Welding tool for assembling electric tricycle

An electric tricycle and welding tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of uneven welding seam, affecting the automatic welding efficiency and welding quality of the frame, and insufficient alignment accuracy of steel pipes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

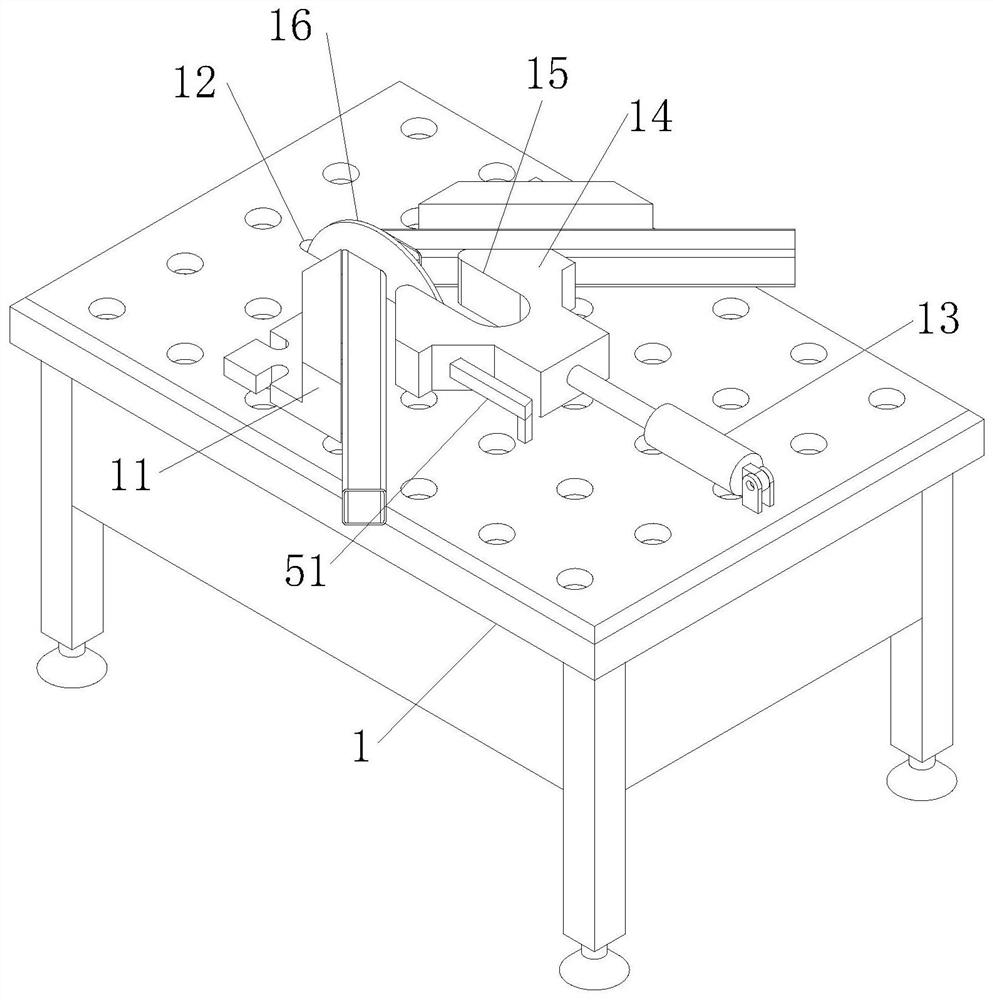

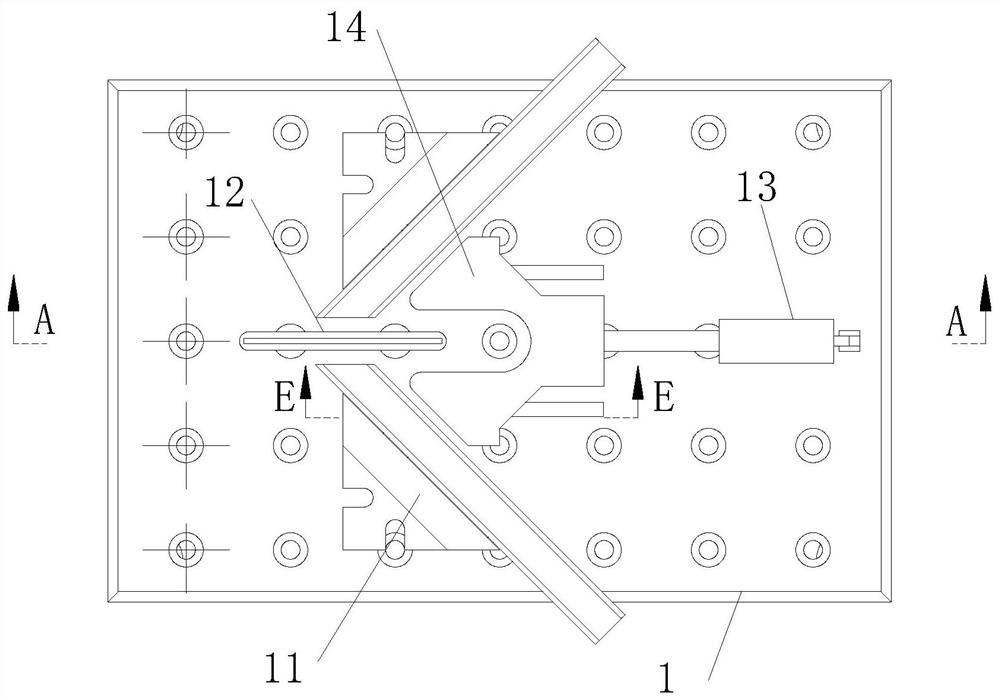

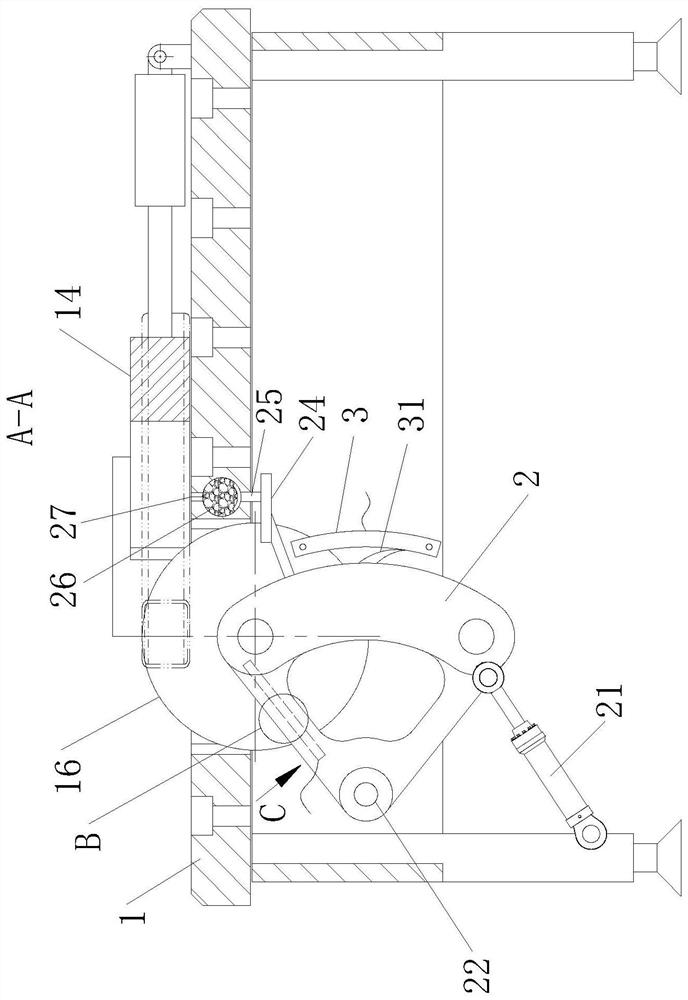

[0031] Such as Figure 1 to Figure 6 As shown, a welding tool for electric tricycle assembly according to the present invention includes a tooling platform body 1; a group of fixing holes are evenly distributed on the top of the tooling platform body 1, and a pair of vertically arranged holes are fixed on the top of the tooling platform body 1 through bolts. The limit block 11; the top of the tooling table top block body 1 between the two limit blocks 11 is provided with a through groove 12, and the side of the tooling table body 1 is hinged with the corresponding position of the through groove 12. The U-shaped groove 15 has a cylinder 13 The end of the piston rod of the cylinder 13 is fixedly connected with a right-angled top block 14, and the side of the top block 14 near the through groove 12 is provided with a U-shaped groove 15; the bottom of the tooling table body 1 is provided with a jacking unit, The jacking unit and the corresponding position of the through groove 12 ...

Embodiment 2

[0040] Such as Figure 7 As shown, a slag discharge hole 55 is opened in the top block 14 on the side away from the cylinder 13 of the roller 52, and the side of the slag discharge hole 55 communicates with the cavity through an inclined surface 56, and the slag discharge hole 55 runs through the top block 14 and the slag discharge The hole 55 is arranged parallel to the axial direction of the roller 52, and an auger 58 is connected to the slag discharge hole 55 through the rotating shaft 57; the rotating shaft 57 and the roller 52 are driven by a figure-eight belt; 58 rotates, the welding slag scooped up by the cutter 53 on the top of the tooling table body 1 is discharged by the auger 58 after being transported by the inclined plane 56, reducing the residue of the welding slag at the cavity and increasing the efficiency of the cutter 53 to scrape the welding slag.

[0041] The bottom of the slag discharge hole 55 is provided with a set of return holes 6, the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com