A kind of preparation method of superhydrophobic antistatic transparent coating

A transparent coating and water-resistant technology, applied in coatings, conductive coatings, devices for coating liquid on the surface, etc., can solve the problems of easy accumulation of dust, single function, and poor dust prevention, and achieve the goal of reducing accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

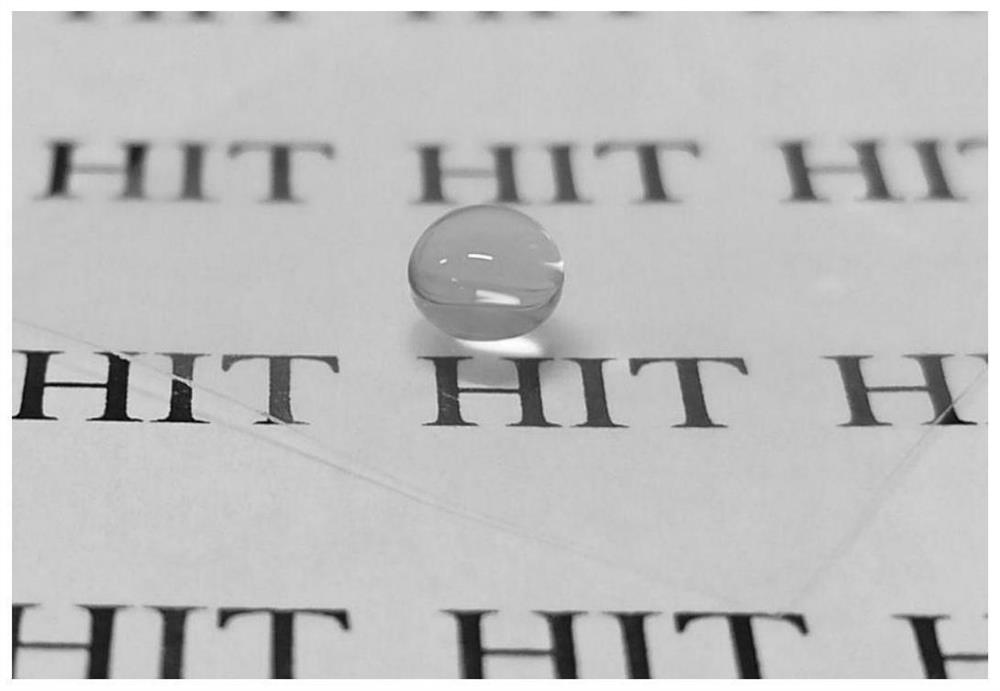

Embodiment 1

[0026] Apply the coating to the polyimide film surface:

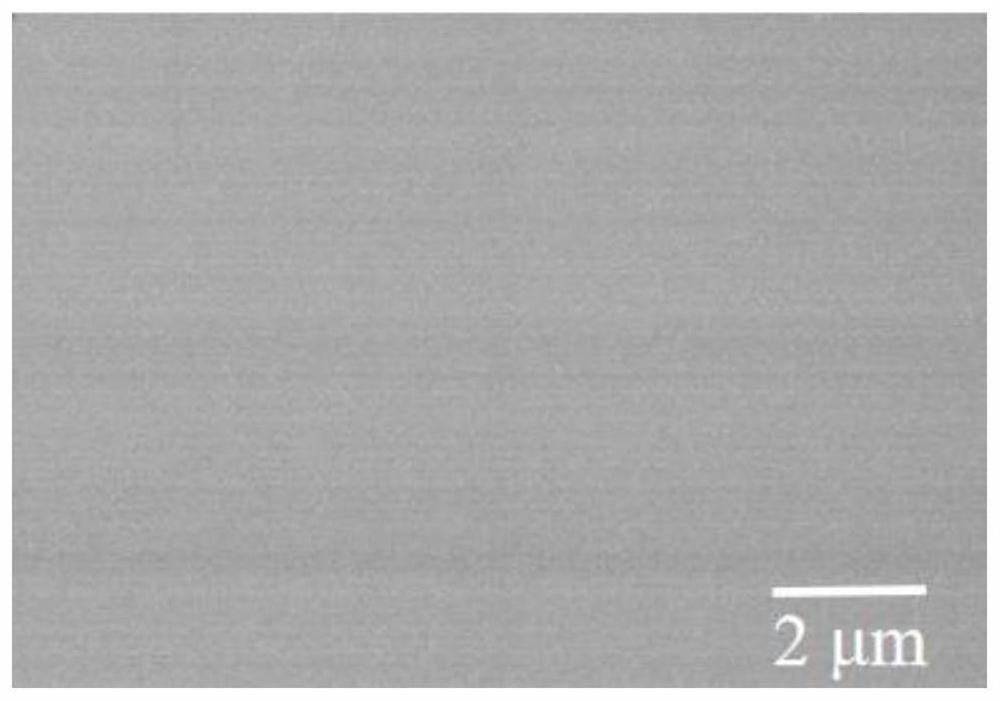

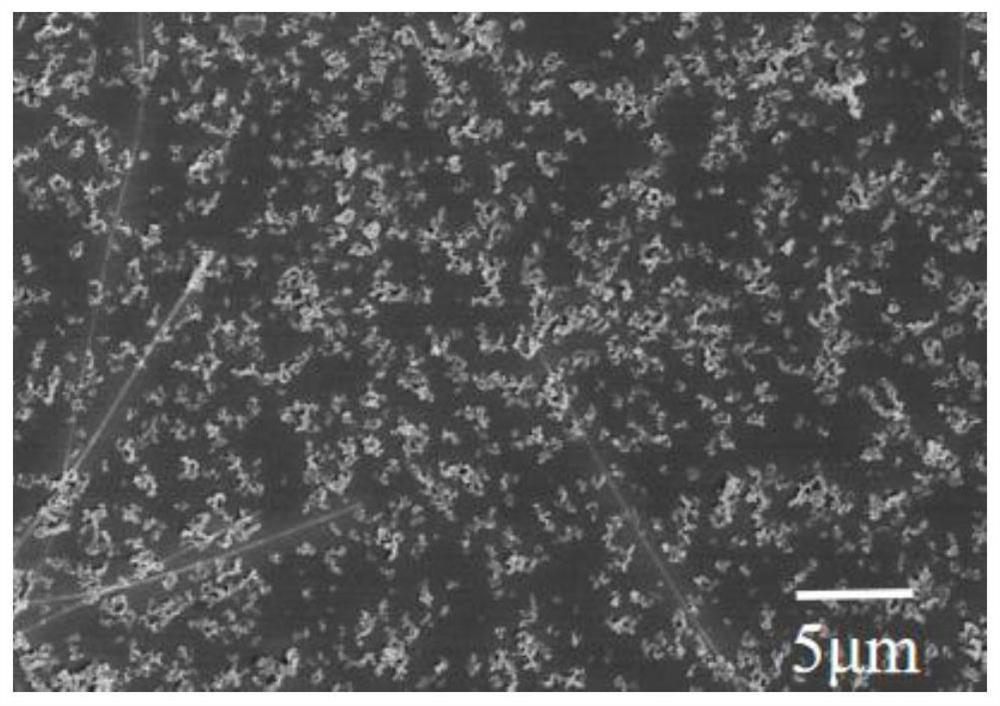

[0027] Step 1: Weigh nano-silica and add it to absolute ethanol. After magnetically stirring for 15 minutes, ultrasonically disperse for 15 minutes to obtain a uniform nano-silica dispersion. Put the nano-silica dispersion in a container and control the temperature of the oil bath. At 50°C, stir magnetically at the same time; add ethyl orthosilicate, stir for 15 minutes, add hexamethyldisilazane, add deionized water after 30 minutes, and continue to react for 6 hours to obtain a hydrophobic silica sol;

[0028] Step 2: Weigh 1 g of the hydrophobic silica sol obtained in Step 1, add 5 g of absolute ethanol, and sonicate at room temperature for 30 minutes to obtain a uniform hydrophobic silica coating solution.

[0029] Step 3: Prepare a silver nanowire solution with a concentration of 3 wt%, clean the transparent polyimide film with ethanol ultrasonically, and then dry it. Take the dried transparent polyimide film and s...

Embodiment 2

[0033] Apply the coating to the glass surface:

[0034] Step 1: Weigh nano-silica and add it to absolute ethanol. After magnetically stirring for 15 minutes, ultrasonically disperse for 15 minutes to obtain a uniform nano-silica dispersion. Put the nano-silica dispersion in a container and control the temperature of the oil bath. At 50°C, stir magnetically at the same time; add ethyl orthosilicate, stir for 15 minutes, add hexamethyldisilazane, add deionized water after 30 minutes, and continue to react for 6 hours to obtain a hydrophobic silica sol;

[0035] Step 2: Weigh 1 g of the hydrophobic silica sol obtained in Step 1, add 5 g of absolute ethanol, and sonicate at room temperature for 30 minutes to obtain a uniform hydrophobic silica coating solution.

[0036] Step 3: Prepare a silver nanowire solution with a concentration of 3 wt%, clean the transparent glass with acetone ultrasonically, and then dry it. Take the dried transparent glass and soak it in the silver nanowi...

Embodiment 3

[0040] To apply the coating to a clear PET surface:

[0041] Step 1: Weigh nano-silica and add it to absolute ethanol. After magnetically stirring for 15 minutes, ultrasonically disperse for 15 minutes to obtain a uniform nano-silica dispersion. Put the nano-silica dispersion in a container and control the temperature of the oil bath. At 50°C, stir magnetically at the same time; add ethyl orthosilicate, stir for 15 minutes, add hexamethyldisilazane, add deionized water after 30 minutes, and continue to react for 6 hours to obtain a hydrophobic silica sol;

[0042] Step 2: Weigh 1 g of the hydrophobic silica sol obtained in Step 1, add 5 g of absolute ethanol, and sonicate at room temperature for 30 minutes to obtain a uniform hydrophobic silica coating solution.

[0043] Step 3: A gold nanowire solution with a concentration of 3 wt % was prepared, and the transparent PET was ultrasonically cleaned with acetone and then dried. The dried transparent PET was soaked into the gold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com