Microwave preparation method and application of graphene/molybdenum sulfide/molybdenum oxide heterostructure catalyst

A heterogeneous structure, graphene technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the unfavorable large-scale commercial production, lithium-sulfur batteries are rarely seen, and the operation steps are cumbersome And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

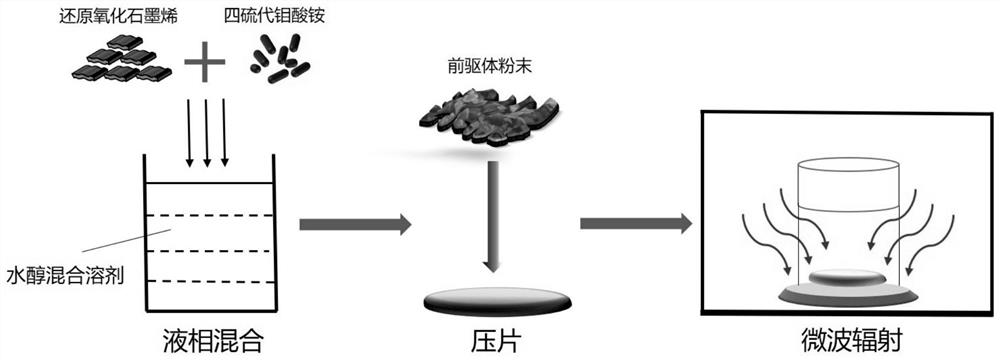

[0045] see figure 1 A microwave preparation method of a graphene / molybdenum sulfide / molybdenum oxide heterostructure catalyst of the present invention comprises the following steps:

[0046] S1. Disperse the reduced graphene oxide powder and ammonium tetrathiomolybdate powder with a mass ratio of 1: (0.5-3) in the same volume of ethanol and deionized water respectively, and then mix, stir and sonicate the two dispersions After processing, a mixed dispersion is obtained;

[0047] Among them, the reduced graphene oxide is selected from few-layer graphene prepared by chemical method;

[0048] The ratio of reduced graphene oxide to ammonium tetrathiomolybdate is 1: (0.5~3), and different MoS can be obtained 2 -MoO 2 content of composite materials.

[0049] S2. Stir and heat the mixed dispersion liquid obtained in step S1 at 60-80°C until it is dried in a solvent to obtain a precursor powder. Take the precursor powder and perform tableting treatment to obtain a precursor tablet...

Embodiment 1

[0056] (1) Take 80mg graphene and disperse it in 10ml ethanol, weigh 80mg ammonium tetrathiomolybdate and dissolve it in 10ml deionized water, then mix, stir, and sonicate the two;

[0057] (2) Stir and heat the mixed dispersion in (1) at 70°C until the solvent is completely dried, take 30mg of powder and press it into a disc with a diameter of 10mm, and the applied pressure is 2Mpa;

[0058] (3) The disc pressed in (2) was packaged in a quartz glass bottle filled with argon, and then placed in a microwave synthesizer with the power set to 750W and the time set to 100s.

Embodiment 2

[0060] (1) Take by weighing 100mg graphene and disperse in 15ml ethanol, take by weighing 120mg ammonium tetrathiomolybdate and dissolve in 15ml deionized water, then mix, stir, ultrasonic;

[0061] (2) Stir and heat the mixed dispersion in (1) at 70°C until the solvent is completely dried, take 50mg of powder and press it into a disc with a diameter of 12mm, and the applied pressure is 2Mpa;

[0062] (3) The disc pressed in (2) was packaged in a quartz glass bottle filled with argon, and then placed in a microwave synthesizer with the power set to 800W and the time set to 120s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com