Waste liquid treatment device in PCB (printed circuit board) production process

A technology for waste liquid treatment and production process, applied in the field of electronic technology, which can solve the problems of low copper recovery efficiency and clogging of filters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

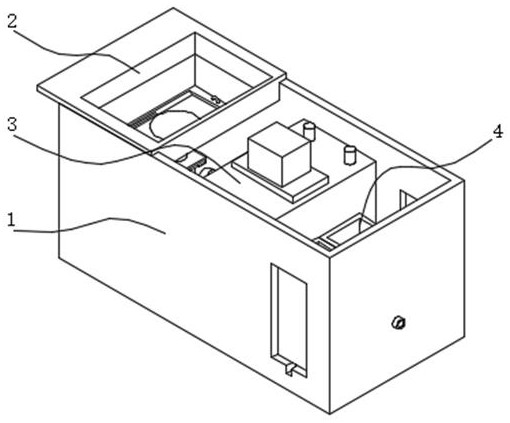

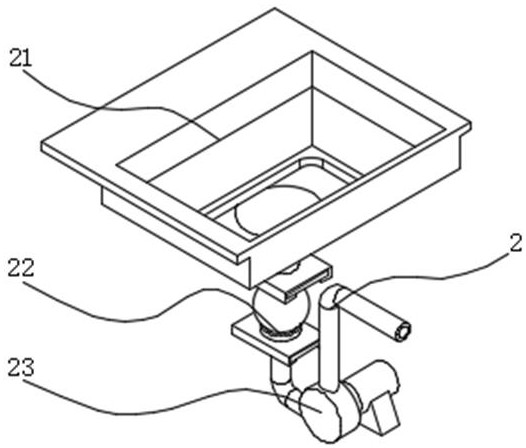

[0033] see Figure 1-8 As shown, the present invention is a waste liquid treatment device in the PCB production process, including a support base 1, a preliminary filter part 2, a stirring mechanism 3 and a secondary filter part 4, the preliminary filter part 2 is placed on the support base 1, and the stirring mechanism 3 is connected to the primary filter part 2 through pipelines, the stirring mechanism 3 is slidably connected to the secondary filter part 4 , and the secondary filter part 4 is slidably connected to the support base 1 .

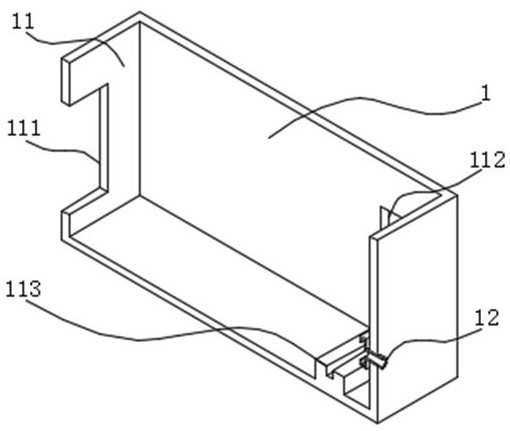

[0034] Among them such as Figure 1-5As shown, the support base 1 includes a support part 11 and a first water outlet part 12. One end of the support part 11 is provided with an observation port 111, and the end of the support part 11 far aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com