Voltage-sharing element applied to power equipment and design method of voltage-sharing element

A technology of power equipment and components, applied in the field of voltage equalizing components and its design, can solve the problems of high R&D cost and long R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

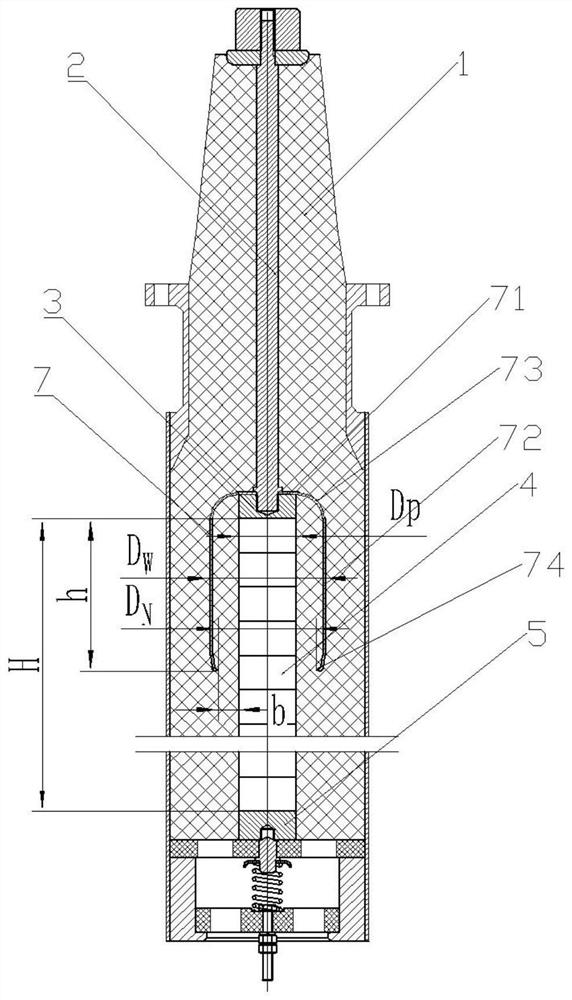

[0102] Such as figure 1 As shown, the electrical equipment in this embodiment is a shielded plug-in lightning arrester, including an insulating layer 1, a first conductor 2, a second conductor 3, a valve body 4 and a first conductor located in the insulating layer 1 and arranged in sequence according to the current transmission direction. three conductors 5;

[0103] The pressure equalizing element 7 is made of conductive or semi-conductive material, including the bottom of the barrel and the barrel body; the bottom of the barrel is a first disc 71 with fixing holes, the barrel body is a thin-walled cylindrical structure 72, and the bottom of the first disc 71 The surface is electrically connected to the upper surface of the second conductor 3, the upper end of the thin-walled cylindrical structure 72 is connected to the edge of the first disc 71 through a circular arc transition section 73, and the other end extends toward the direction of the third conductor 5, and the thin-...

Embodiment 2

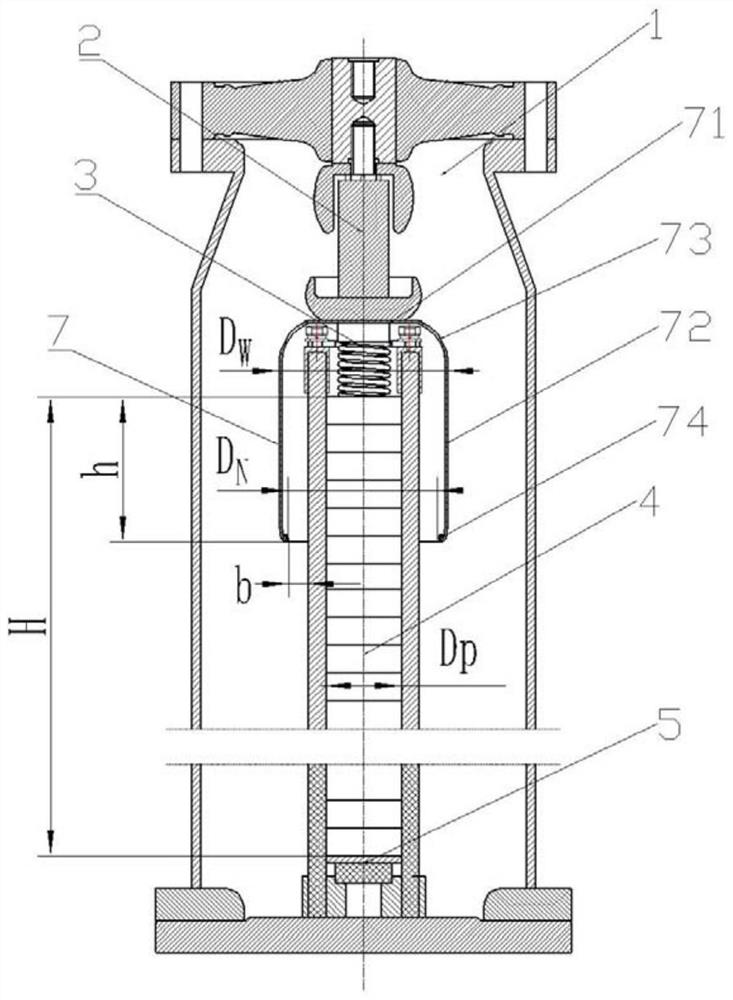

[0148] Such as figure 2 As shown, the power equipment in this embodiment is a GIS arrester, including an insulating layer 1, a first conductor 2, a second conductor 3, a valve body 4 and a third conductor 5 located in the insulating layer 1 and arranged in sequence according to the current transmission direction ; The difference from Example 1 is that the insulating layer 1 of the arrester is made of SF6 gas.

[0149] The pressure equalizing element 7 is made of conductive or semi-conductive materials, including the bottom of the barrel and the barrel; the bottom of the barrel is a first disc 71, and the barrel is a thin-walled cylindrical structure 72. The lower surface of the first disc 71 is connected to the second conductor. The upper surface of the thin-walled cylindrical structure 72 is electrically connected to the upper surface of the thin-walled cylindrical structure 72. The upper end of the thin-walled cylindrical structure 72 is connected to the edge of the first d...

Embodiment 3

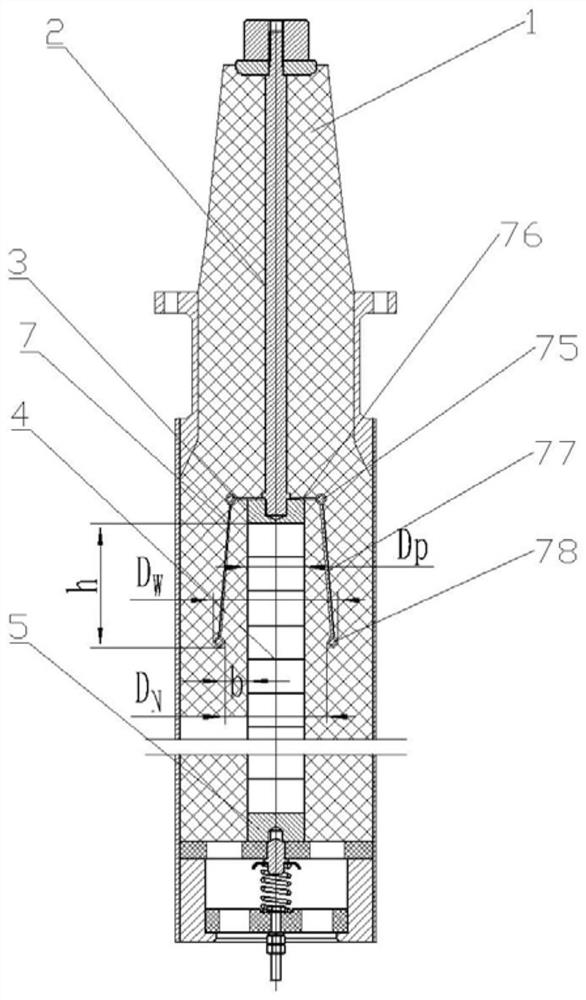

[0194] Such as image 3 As shown, the electric equipment in this embodiment is the same as that in Embodiment 1, and it is also a shielded plug-in lightning arrester, including an insulating layer 1, a first conductor 2 and a second conductor located in the insulating layer 1 and arranged in sequence according to the current transmission direction 3. The valve body 4 and the third conductor 5;

[0195] The pressure equalizing element 7 is made of conductive or semi-conductive material, including the bottom of the barrel and the barrel body; the bottom of the barrel includes a first ring 75 and a second disc 76, the second disc 76 is sleeved outside the first conductor 2, and the second The lower surface of the second disk 76 is electrically connected to the upper surface of the second conductor 3, and the outer edge of the second disk 76 is provided with the first ring 75; the barrel includes some connecting ribs 77 and the second ring 78; The circular ring 78 is arranged par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com