Resistive layer material, memristor and preparation method thereof

A technology of resistive layer and memristor, which is applied in the direction of electrical components, can solve the problems of changes in multiple resistance states, and it is difficult to simulate the plasticity of human brain synapses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

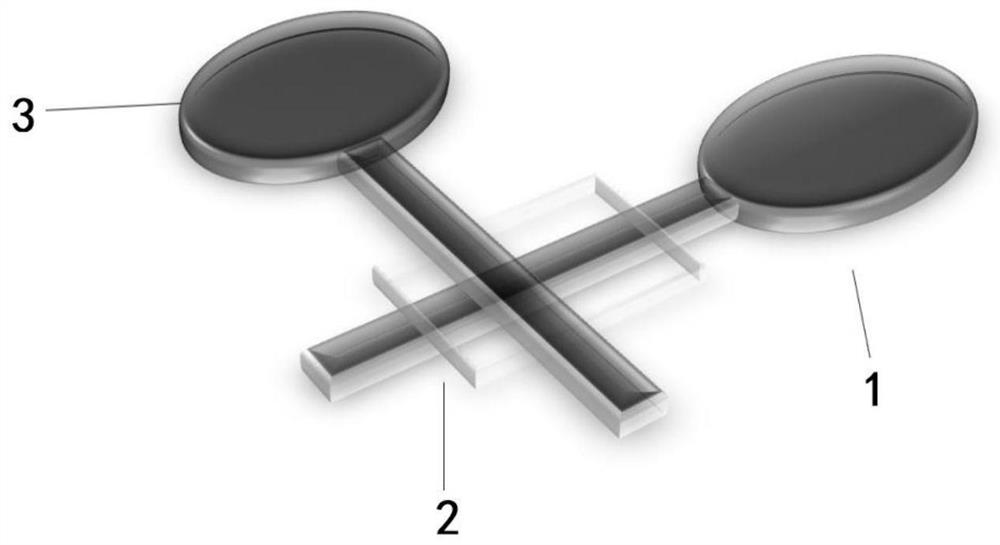

[0037] Such as figure 1 As shown, the present embodiment provides a memristor, and its preparation method is as follows:

[0038] (1) 36mg carboxylated chitosan, 24mg polyvinyl alcohol (PVA) and 40mg ammonium nitrate (NH 4 NO 3 ) was dissolved in 10mL deionized water to obtain the resistive layer material;

[0039] (2) Forming a W electrode 1 with a thickness of 50 nm on the glass substrate by a sputtering process;

[0040] (3) Spin-coat the resistive layer material prepared in step (1) on the W electrode 1 prepared in step (2) to form a resistive layer 2 with a thickness of 200 nm;

[0041] (4) An Ag electrode 3 with a thickness of 50 nm is formed on the resistive layer 2 prepared in step (3) by using an electron beam evaporation process to obtain a memristor.

Embodiment 2

[0043] Such as figure 1 As shown, the present embodiment provides a memristor, and its preparation method is as follows:

[0044] (1) 48mg carboxylated chitosan, 12mg polyvinyl alcohol (PVA) and 40mg ammonium nitrate (NH 4 NO 3 ) was dissolved in 10ml deionized water to obtain the resistive layer material;

[0045] (2) Forming a W electrode 1 with a thickness of 100 nm on a glass substrate by a sputtering process;

[0046] (3) Spin-coat the resistive layer material prepared in step (1) on the W electrode 1 prepared in step (2) to form a resistive layer 2 with a thickness of 500 nm;

[0047] (4) An Ag electrode 3 with a thickness of 100 nm is formed on the resistive layer 2 prepared in step (3) by using an electron beam evaporation process to obtain a memristor.

experiment example

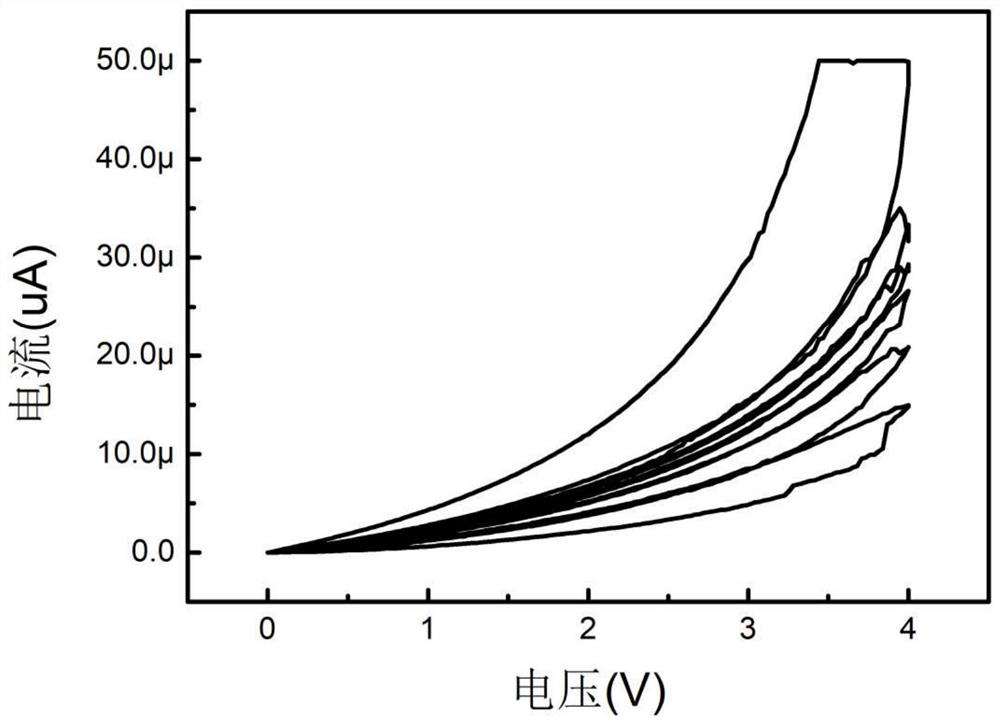

[0049] Such as figure 2 As shown, using the Agilent B1500A semiconductor tester, the W electrode is grounded, the Ag electrode is connected to the positive electrode, and a voltage of 4V is applied to the device for scanning test. As the number of scans continues to increase, it can be found that the current is constantly increasing and the conductance is constantly changing. , the resistance of the resistive layer keeps decreasing.

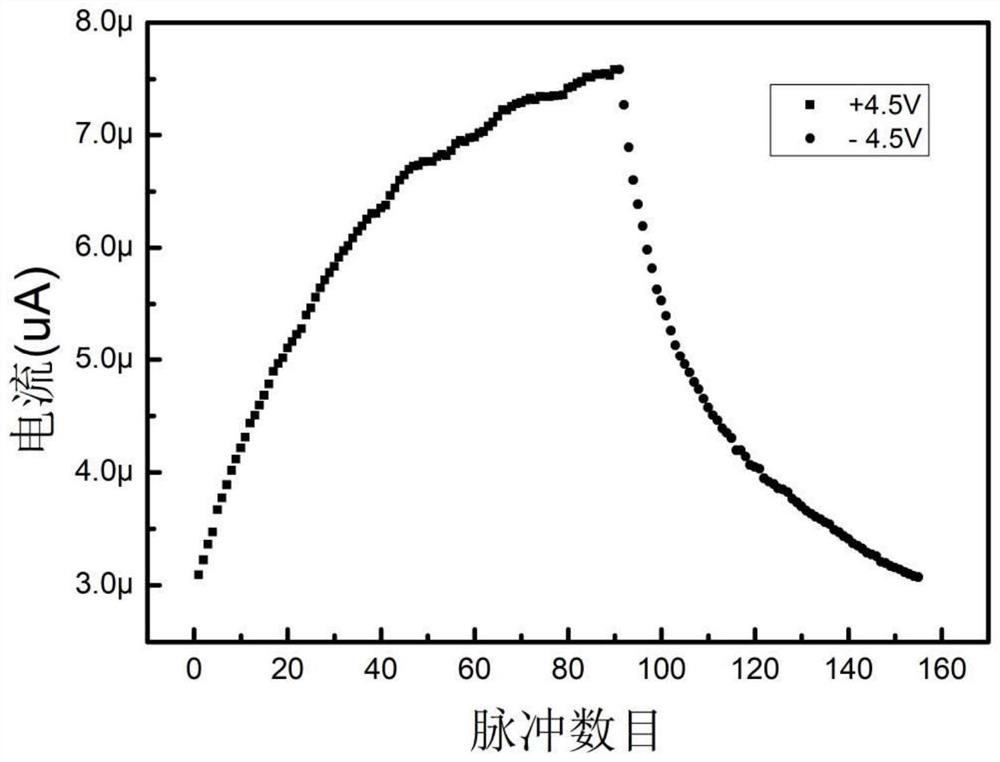

[0050] Such as image 3 As shown, using the Keithley 2636B semiconductor tester to apply 90 consecutive positive pulse voltages of 4.5V to the device, the read voltage of 0.5V (pulse interval is 60ms) is limited to 500uA, and the conductance of the device gradually increases from 3uA to 7.5 uA, continuous application of 80 reverse -4.5V pulse voltages, -0.5V read voltage (pulse interval 60ms), the conductance of the device dropped from 7.5uA to 3uA.

[0051] Such as Figure 4As shown, using Keithley 2636B semiconductor tester to apply 400 con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com