Fluorine modified activated carbon electrode surface composite treatment method and application thereof

A composite treatment, electrode surface technology, applied in the field of electrochemistry, can solve problems such as difficulty in meeting energy requirements, limited use scenarios of supercapacitors, and low energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Measure 2600 μL of N-methylpyrrolidone, weigh 500 mg of polyvinylidene fluoride, add polyvinylidene fluoride to N-methylpyrrolidone, and stir for 2 hours at a speed of 400 r / min with a magnetic stirrer until polyvinylidene fluoride Completely dissolve ethylene powder in N-methylpyrrolidone; weigh 500mg of conductive agent Super P and 4000mg of activated carbon, add them into the system and stir at 400r / min for 12h at room temperature; finally use a micro ball mill to mill for 6min with a vibration frequency of 50Hz , to obtain a uniform electrode slurry.

[0066] Use a 100 μm doctor blade to coat the electrode slurry on carbon-coated aluminum foil, put it in a blast drying oven for 2 hours at 80°C, and then put it in a vacuum drying oven for 12 hours at 80°C to obtain a pole piece.

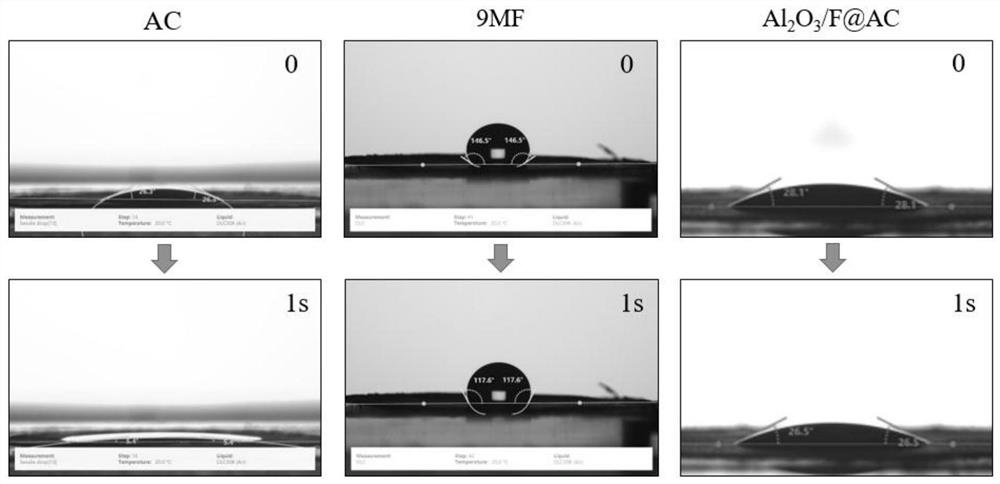

[0067] Put the pole piece into a low-temperature plasma processing device, the gas in the treatment cabin is carbon tetrafluoride, the power supply is set to 80W, the air pressure in the ca...

Embodiment 2

[0070] Measure 2200 μL of N-methylpyrrolidone, weigh 500 mg of polyvinylidene fluoride, add polyvinylidene fluoride to N-methylpyrrolidone, and stir for 3 hours at a speed of 300 r / min with a magnetic stirrer until polyvinylidene fluoride Completely dissolve ethylene powder in N-methylpyrrolidone; weigh 500mg of conductive agent Super P and 4000mg of activated carbon, add to the system and stir at 300r / min for 12h at room temperature; finally use a micro ball mill for 3min, vibration frequency 30Hz , to obtain a uniform electrode slurry.

[0071] Use a 150 μm scraper to coat the electrode slurry on the carbon-coated aluminum foil, put it in a blast drying oven for 4 hours at 60°C, and then put it in a vacuum drying oven for 16 hours at 60°C to obtain a pole piece.

[0072] Put the pole piece into a low-temperature plasma processing device, the gas in the treatment chamber is carbon tetrafluoride, the power supply is set to 100W, the air pressure in the chamber is 60Pa during t...

Embodiment 3

[0075] Measure 2400 μL of N-methylpyrrolidone, weigh 400 mg of polyvinylidene fluoride, add polyvinylidene fluoride to N-methylpyrrolidone, and stir for 2 hours at a speed of 400 r / min with a magnetic stirrer until polyvinylidene fluoride Completely dissolve ethylene powder in N-methylpyrrolidone; weigh 400mg of conductive agent Super P and 4000mg of activated carbon, add them into the system and stir at 400r / min for 13h at room temperature; finally use a micro ball mill for 2min, vibration frequency 150Hz , to obtain a uniform electrode slurry.

[0076] Use a 200 μm doctor blade to coat the electrode slurry on carbon-coated aluminum foil, put it in a blast drying oven for 2 hours at 90°C, and then put it in a vacuum drying oven for 16 hours at 120°C to obtain a pole piece.

[0077] Put the pole piece into the low-temperature plasma processing device, the gas in the treatment chamber is carbon tetrafluoride, the power supply is set to 150W, the air pressure in the chamber is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

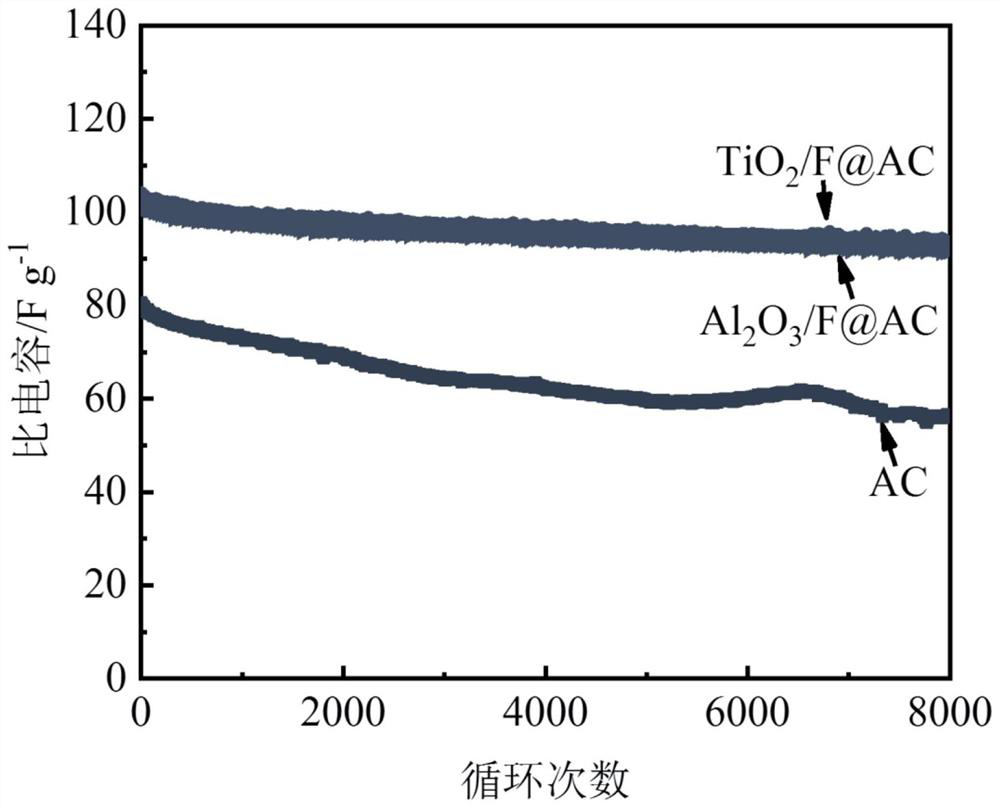

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com