Safety monitoring and evaluating system for wall temperature of heating surface in boiler

An evaluation system and safety monitoring technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of numerical simulation result verification, uncertainty of result reliability, and inability to achieve real-time performance, so as to reduce monitoring deviation , Accurate online real-time feedback of wall temperature changes, and the effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] A safety monitoring and evaluation system for heating surface wall temperature in a boiler includes an online calculation module for furnace tube wall temperature and a wall temperature safety evaluation display module.

[0035] The furnace tube wall temperature online calculation module, the specific steps are as follows:

[0036] S1: Collect real-time status parameters of boiler operation through the remote monitoring platform, including furnace structure parameters, coal quality parameters, burner operation status, flue gas temperature, flue gas flow rate, working medium temperature, working medium flow rate, and working medium pressure;

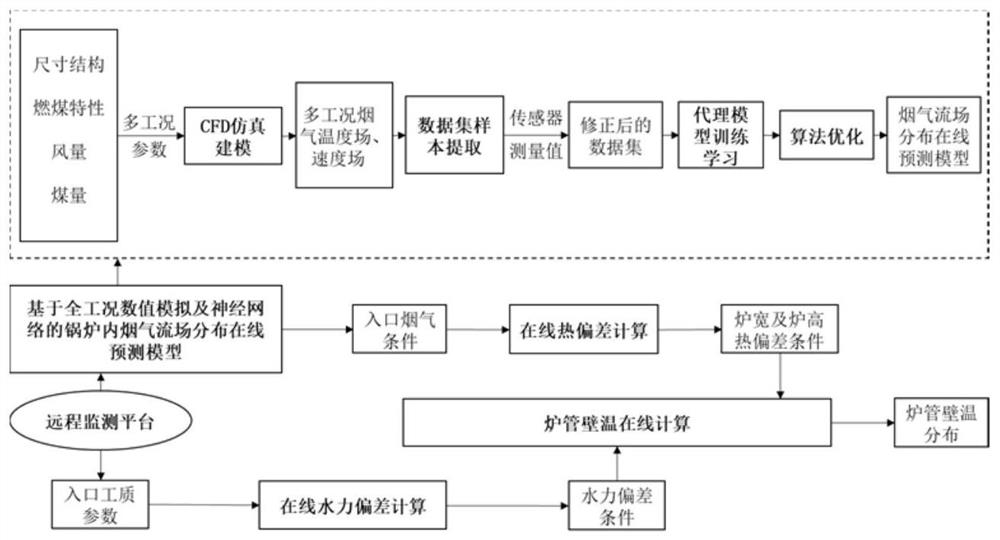

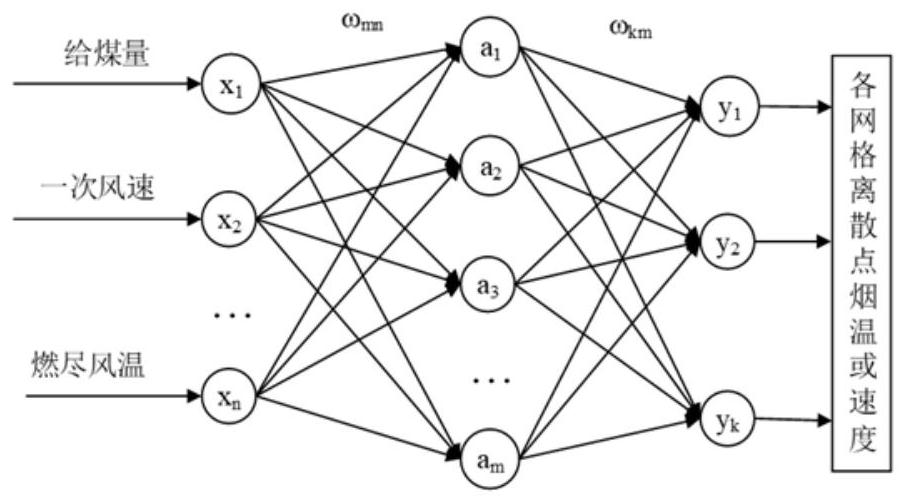

[0037] S2: Substituting the above parameters into the online prediction model of the flue gas flow field distribution in the boiler based on the numerical simulation of the full working conditions and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com