Rare earth extraction and separation process component content digital twinningning characteristic analyzing method

A rare earth extraction and separation, component content technology, applied in instruments, control/regulation systems, simulators, etc., can solve the problems of low fault tolerance, long production cycle, large industrial volume, etc., to achieve accurate analysis and reasonable control, The effect of shortening the operating cycle and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

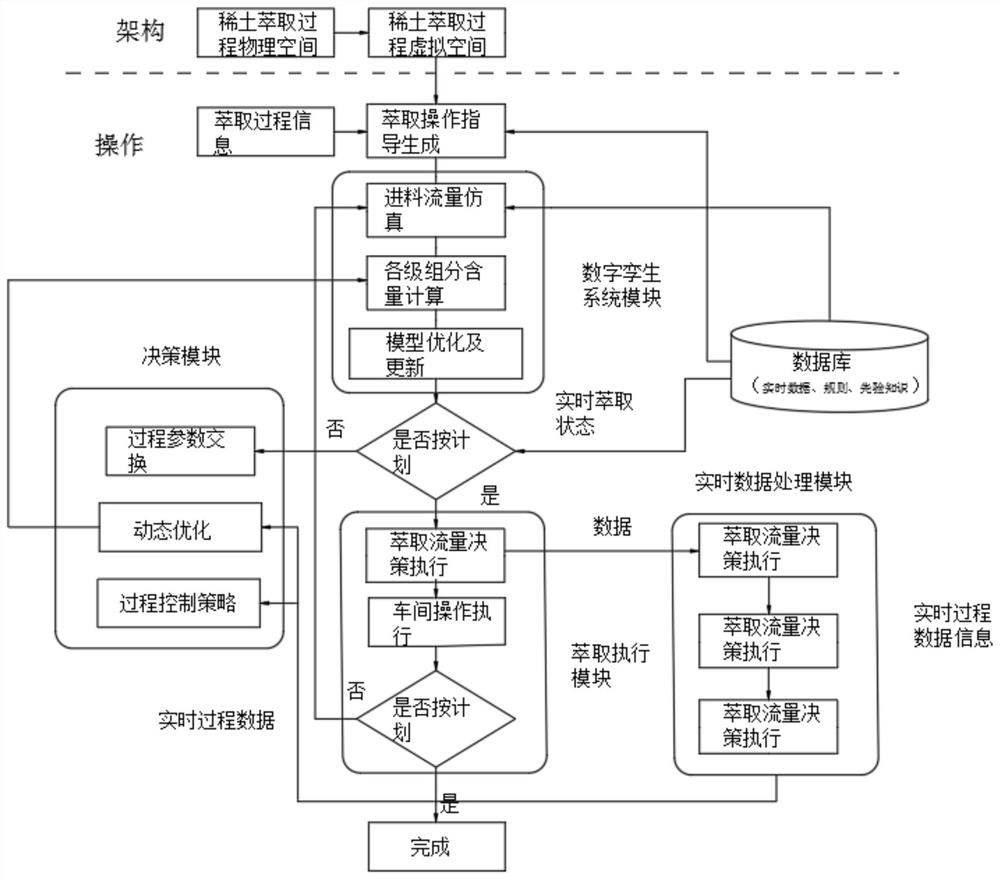

[0030] In order to better understand the purpose, structure and function of the present invention, a digital twin feature analysis method for component content in the rare earth extraction and separation process of the present invention will be further described in detail below in conjunction with the accompanying drawings.

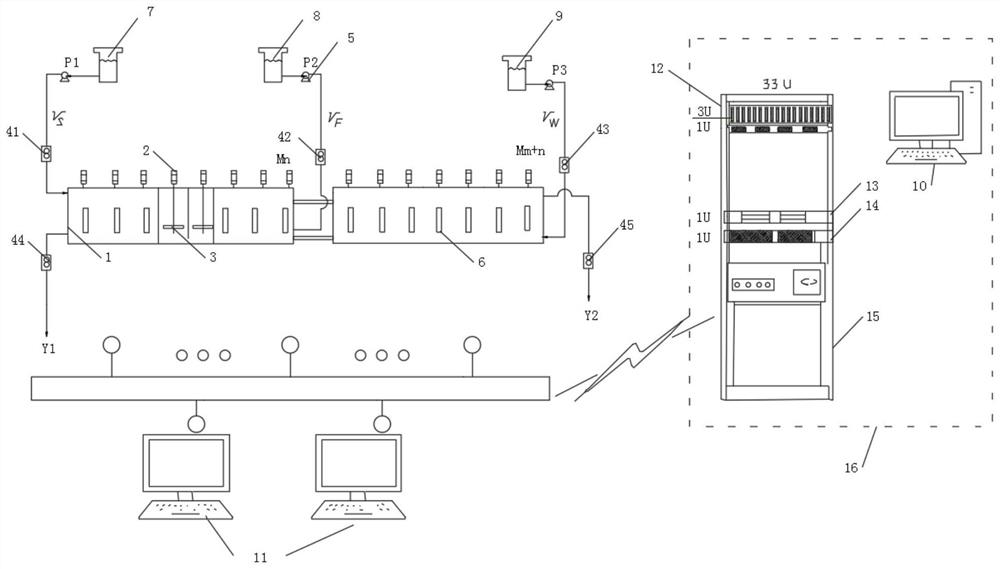

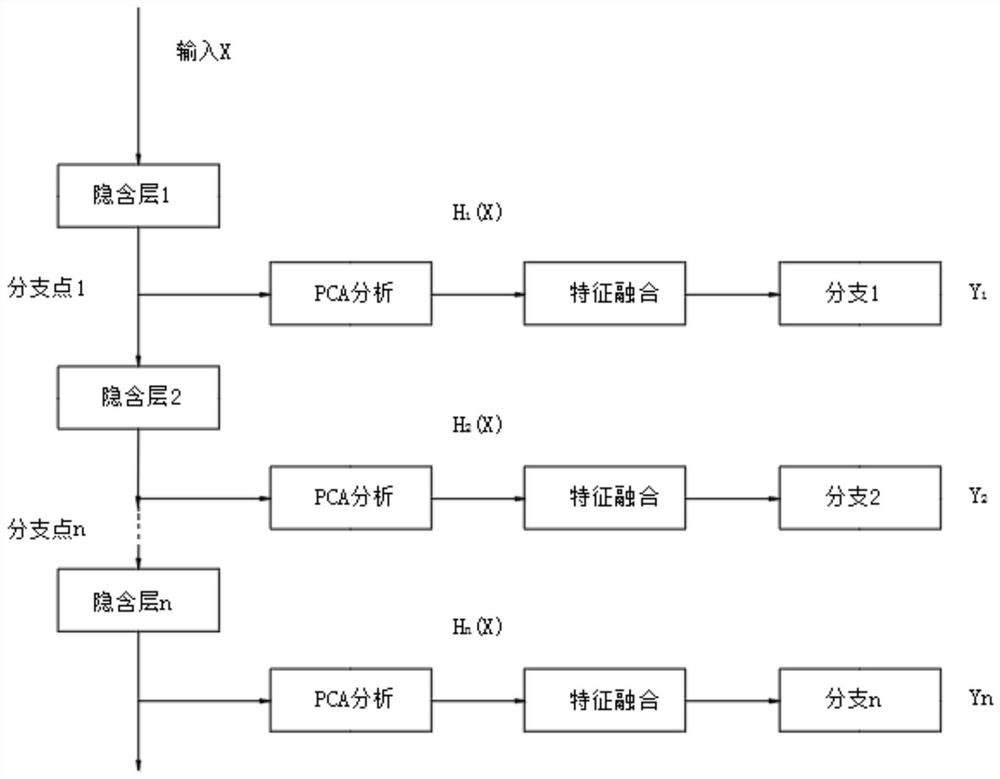

[0031] see Figure 1-5 , the present invention: a rare earth extraction separation process component content digital twin feature analysis method, including rare earth extraction process workshop equipment, a rare earth extraction process simulation platform and a rare earth extraction process component content digital twin system.

[0032] S1: Through the collection and learning of field data, the field real-time data is transmitted to the rare earth extraction process simulation platform of the industrial computer and the data is stored;

[0033] S2: According to the actual production process and data of rare earth extraction, use Siemens Botu software ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com