Semi-quantitative prediction and visualization method for mesoscopic stress and texture in alpha titanium deformation process

A semi-quantitative and textured technology, applied in the field of plastic deformation of materials, can solve the problems of difficulty in realizing texture visualization in the deformation process of α-titanium alloys, difficulty in measuring mesoscopic stress of materials, and high cost of mesoscopic stress measurement in α-titanium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

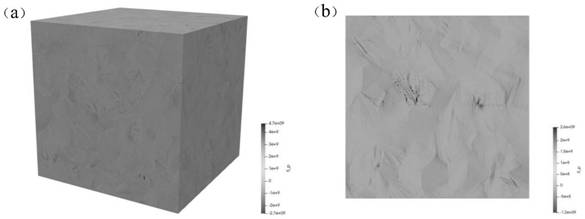

[0054] A method for semi-quantitative prediction and visualization of mesoscopic stress and texture in the deformation process of α-titanium, comprising the following steps:

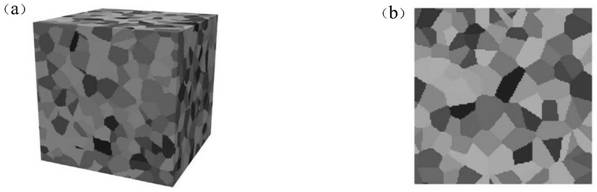

[0055] Step 1. Based on the experimental characterization results of the microstructure of the α-titanium alloy, use the open source software DREAM 3D or DAMASK to establish a representative volume element model RVE including material texture.

[0056] For the XRD measurement results, the specific steps are:

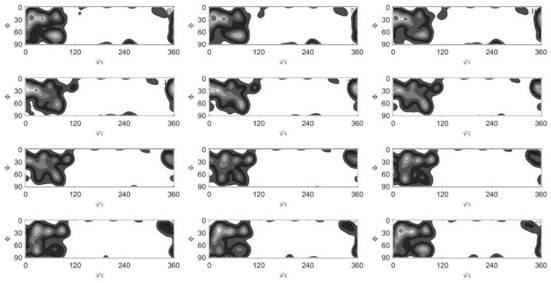

[0057] (1) Obtain the texture data of the material by XRD method (such as figure 1 , including Euler angle data and corresponding weights), and the data format is converted to format 1 text data (*.txt) through a python program, such as figure 2 shown on the left;

[0058] (2) Modify the file header and file type of the text data in format 1 to format 2, such as figure 2 As shown on the right, it is applicable to the hybrid IA pre-processing program disclosed by DAMASK, after processing, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com