Cross-software-platform joint mechanical simulation method considering uneven mechanical property distribution of casting

A technology of software platform and simulation method, applied in design optimization/simulation, informatics, computer material science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

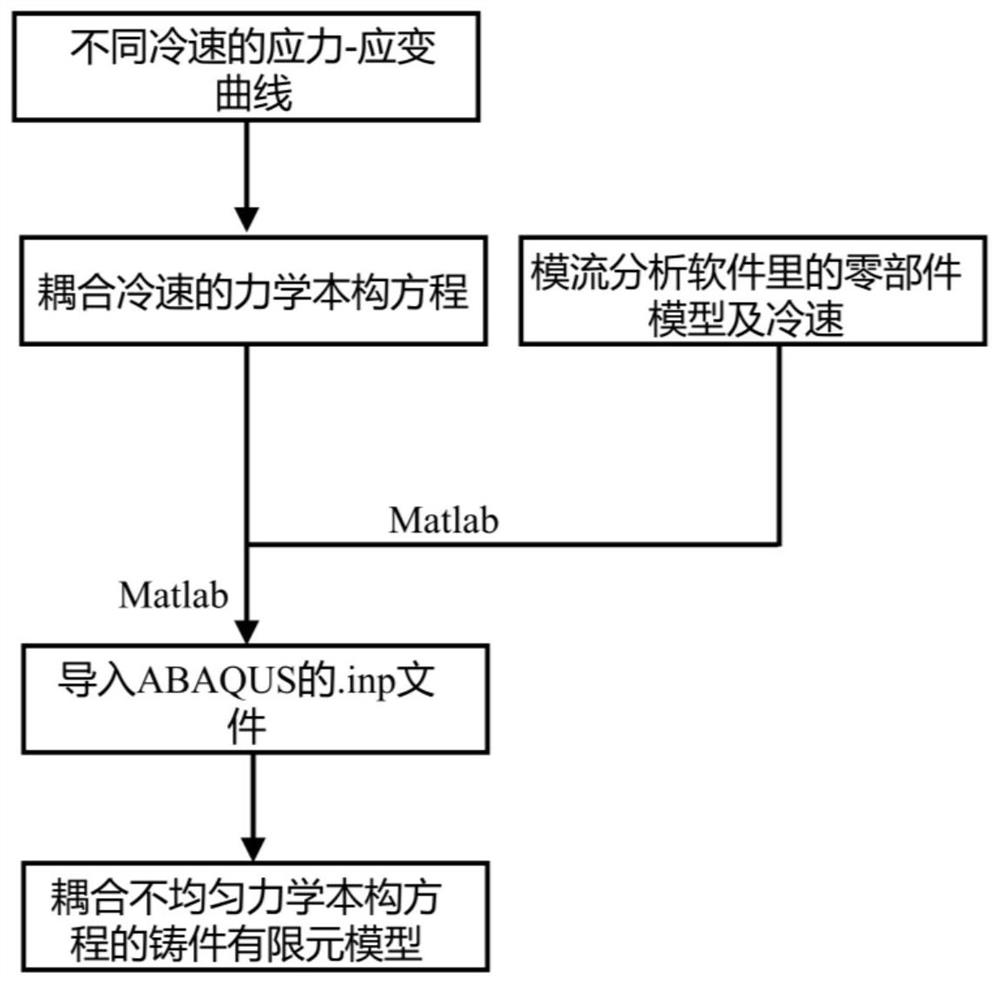

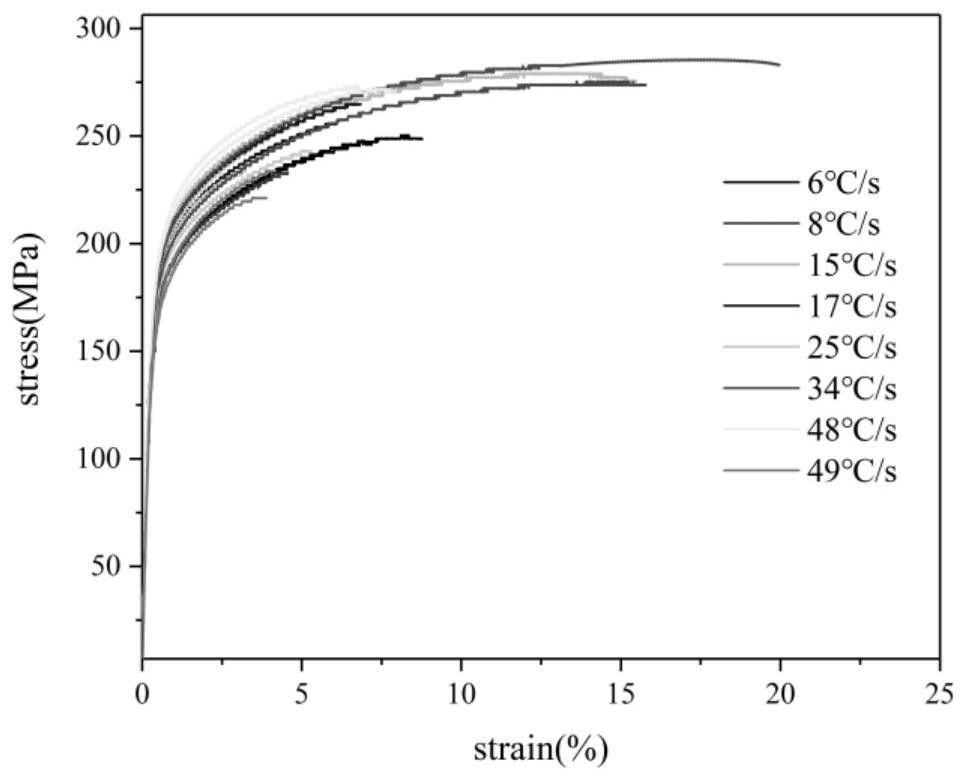

Method used

Image

Examples

specific Embodiment

[0051] The model and cooling rate information are obtained through the ProCAST casting simulation software, and then imported into ABAQUS for mechanical simulation of a typical A356 casting. The specific steps include:

[0052] Step 1. Obtain the mesh file in ProCAST. After the casting simulation is completed, open the g.unf file in the Viewer section, then click Mesh in the upper left corner, and click Export in the File drop-down menu to output the g.inp file.

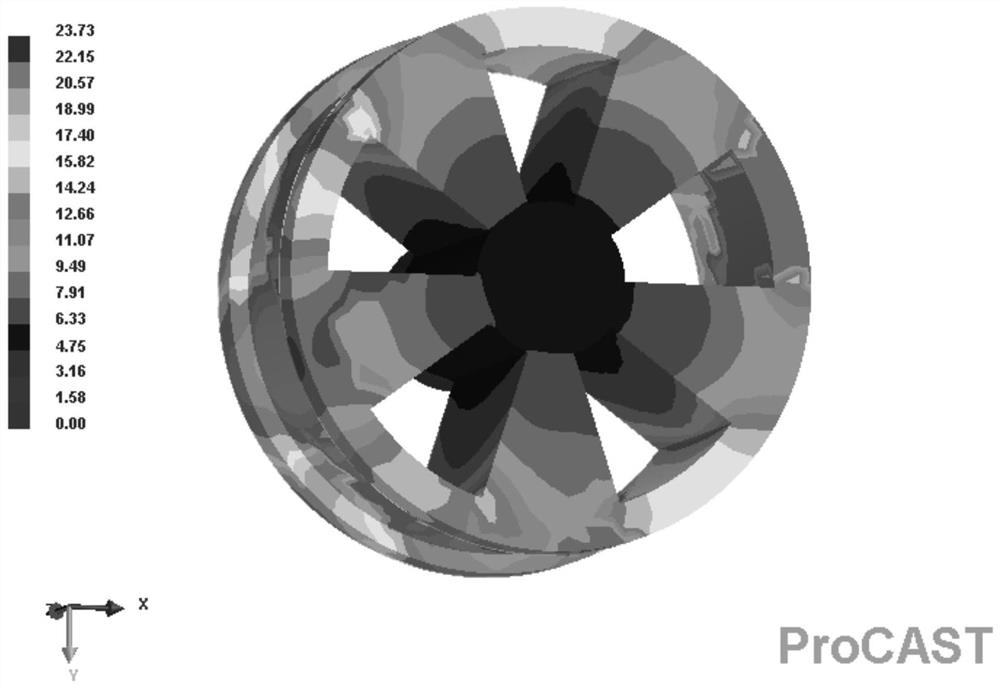

[0053] Step 2. Obtain the cooling rate file in ProCAST. The cooling rate is distributed in three dimensions in the casting such as figure 2 shown. In the Viewer section of ProCAST, click Metallurgical Tools in the pull-down menu of Results, select R, G, L, according to the nyiamacriterion calculation criteria, fill in A with 1, B with 0, C with 1, D with -0.5, and L upper temperature with 615 ( Tliquidus+2), L lower temperature fill in 548 (Tsolidus), R, G temperature fill in 554.5 (Tsolidus+0.1*(Tliquidus-Tsolidu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com