Construction method for representative volume element model of Ni3Al-based alloy

A technology of volume unit and construction method, applied in the field of aerospace materials, can solve the problem that the distribution of the strengthening phase γ' phase is not completely ordered, and achieve the effect of effective mechanical response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

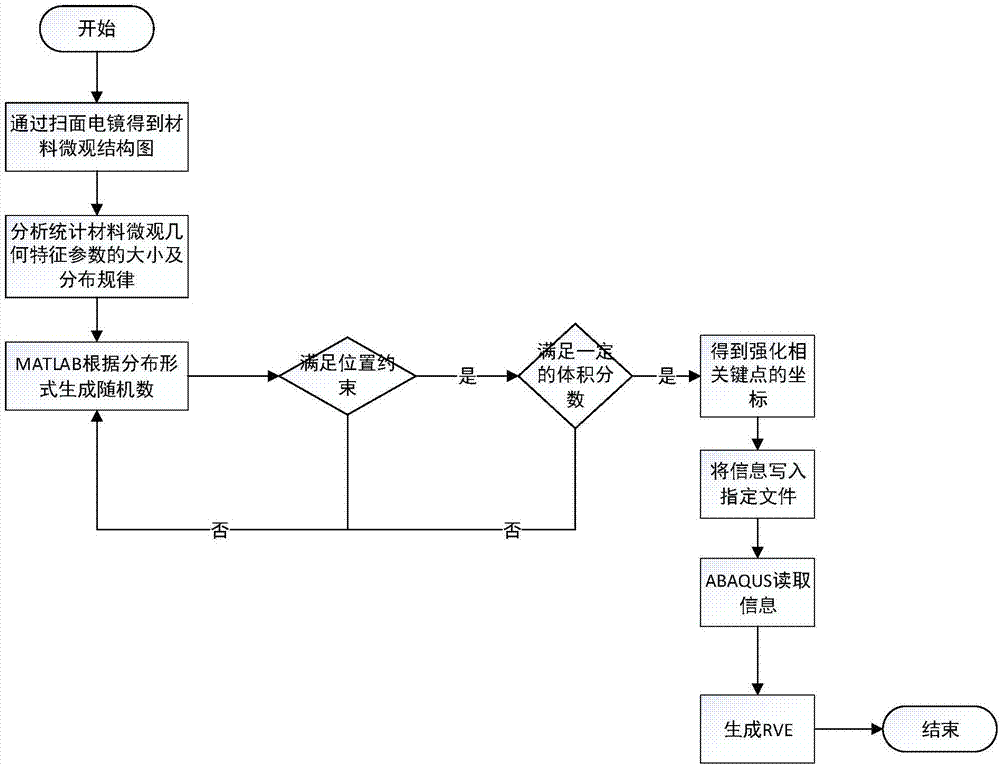

[0059] 1. A kind of Ni 3Al-based alloy representative volume element (RVE) model construction method, such as figure 1 shown, including the following steps:

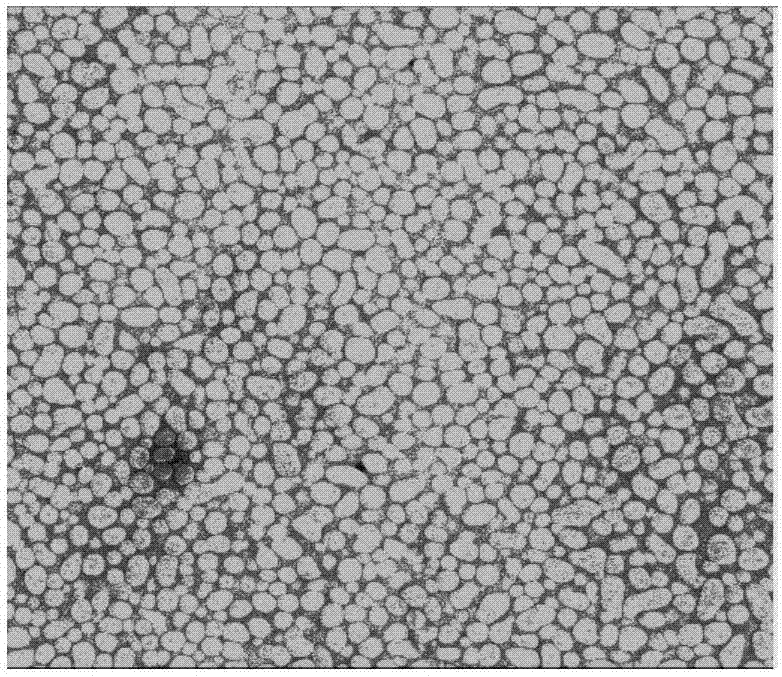

[0060] 1), using a scanning electron microscope to obtain the observation map of the microstructure of the material, such as figure 2 Shown is the microstructure diagram of IC10 alloy;

[0061] 2), by strengthening the phase volume fraction w p , strengthening phase size l p and the strengthening phase shape parameter n p Three microscopic geometric characteristic parameters are used to describe the microstructure observation map of the material.

[0062] 2-1), the volume fraction of strengthening phase (w p )

[0063] In ImagePro plus (IPP) software, the area that needs to be measured in the picture is called AOI (area of interest), and color recognition is one of the most effective methods. This article is the method of color recognition used for Ni 3 The microstructure diagram of the Al-based alloy is iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com