MXene/GO composite coating and preparation method and application thereof

A composite coating and coating technology, applied in the direction of coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of poor bonding between the coating and the substrate, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of MXene / GO composite coating, comprises the following steps;

[0026] Disperse MXene and graphene oxide in water to obtain MXene / GO mixed solution;

[0027] Using the polar plate as the cathode and the anode, and using the MXene / GO mixed solution as the deposition medium, electrophoretic deposition is carried out to obtain a deposited coating;

[0028] The deposited coating is dried to obtain the MXene / GO composite coating.

[0029] In the invention, MXene and graphene oxide are dispersed in water to obtain a mixed solution of MXene / GO.

[0030] In the present invention, the total concentration of the MXene / GO mixed solution is preferably 1 mg / mL.

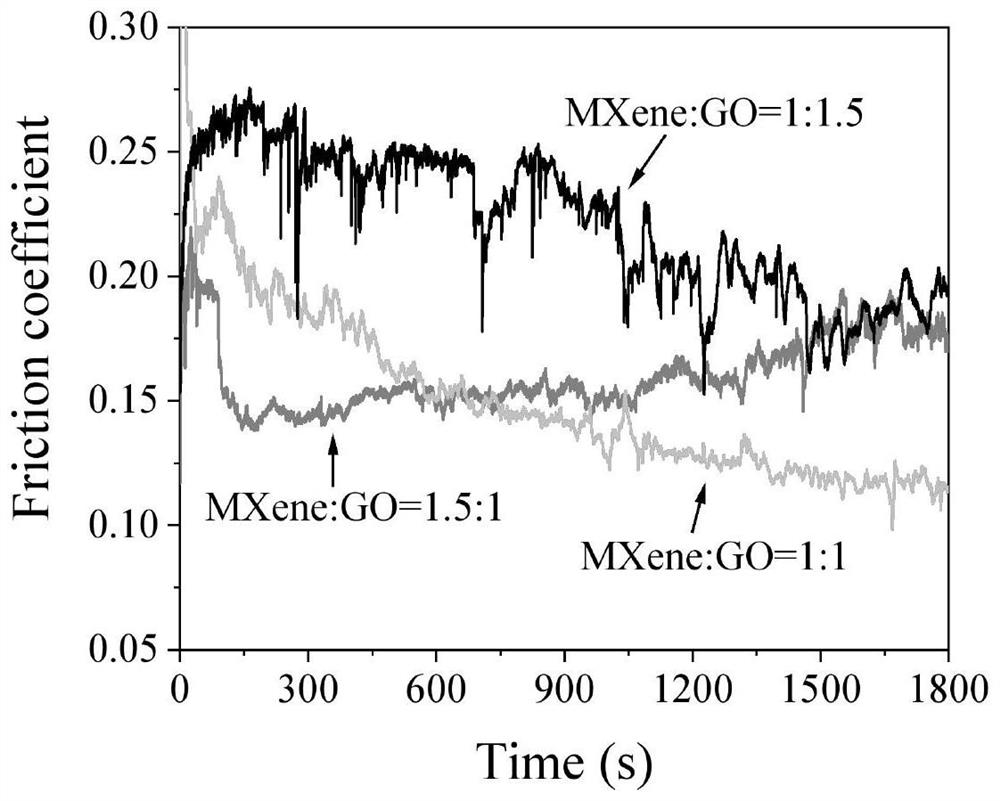

[0031] In the present invention, the preferred mass ratio of MXene to graphene oxide is 1:1.5˜1.5:1, more preferably 1:1.5, 1.5:1 or 1:1.

[0032] In the present invention, the MXene preferably etches Ti by acid and fluoride salt 3 AlC 2 The acid is preferably hydroch...

Embodiment 1

[0047] Step 1. Disperse MXene and GO in ultrapure water, and after 30 min of ultrasonic treatment, the ultrasonic power is 40KHz to obtain a uniformly mixed MXene / GO solution with a concentration of 1 mg / mL, wherein the mass ratio of MXene and GO is 1:1 .

[0048] Step 2: Soak the monocrystalline silicon wafer in piranha solution (concentrated sulfuric acid: 30% hydrogen peroxide=7:3 (V:V)) for 30 minutes. The treated silicon wafer was used as the cathode and the anode, the distance between the cathode and the anode was 15mm, and the mixed solution of MXene / GO was used as the deposition medium, and the electrophoretic deposition was performed at a voltage of 35V for 30min.

[0049]Step 3: Dry the deposited coating at a temperature of 25° C. and a drying time of 4 hours to obtain an MXene / GO composite coating with MXene:GO=1:1.

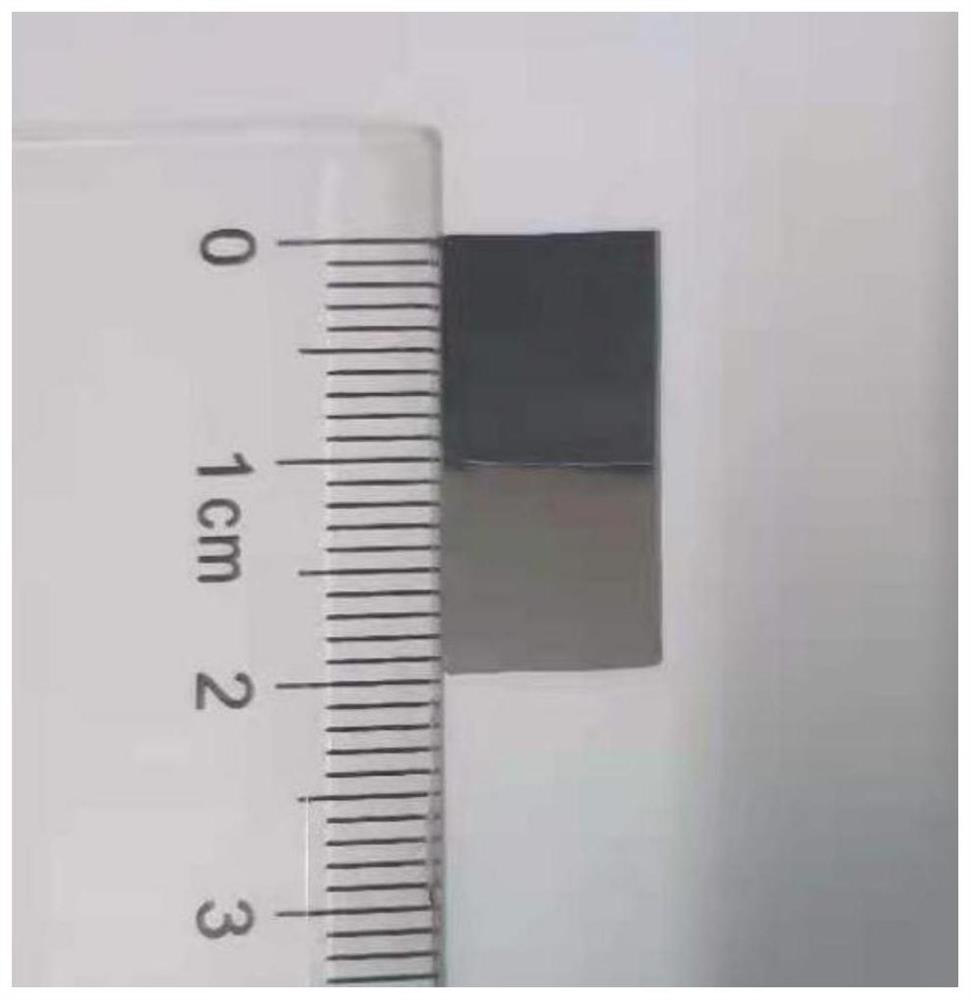

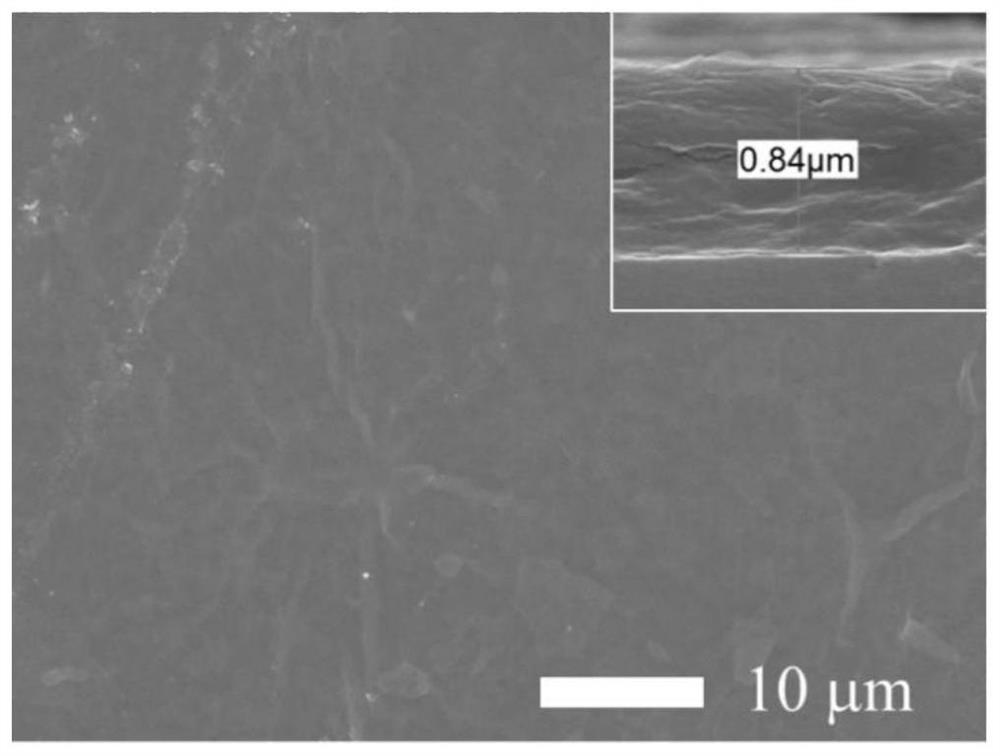

[0050] figure 1 The optical picture of the MXene / GO composite coating that is prepared in embodiment 1; figure 2 For the scanning electron microsc...

Embodiment 2

[0052] Step 1. Disperse MXene and GO in ultrapure water, and after 30 min of ultrasonic treatment, the ultrasonic power is 40KHz to obtain a uniformly mixed MXene / GO solution with a concentration of 1 mg / mL, wherein the mass ratio of MXene and GO is 1.5:1 .

[0053] Step 2: Soak the monocrystalline silicon wafer in piranha solution (concentrated sulfuric acid: 30% hydrogen peroxide=7:3 (V:V)) for 30 minutes. The treated silicon wafer was used as the cathode and the anode, the distance between the cathode and the anode was 15mm, and the mixed solution of MXene / GO was used as the deposition medium, and the electrophoretic deposition was performed at a voltage of 35V for 30min.

[0054] Step 3, drying the deposited coating at room temperature, the temperature is 25° C., and the drying time is 4 hours to obtain an MXene / GO composite coating with MXene:GO=1.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com