Method for comprehensively utilizing and processing spirulina

A processing method and technology of spirulina, applied in the field of food processing, can solve problems such as complicated operation steps, requirements, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

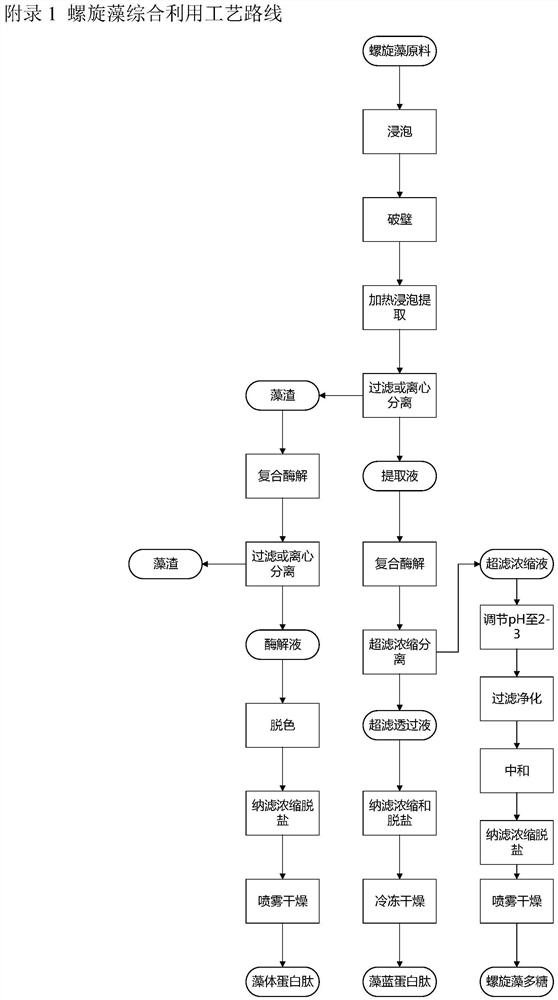

Image

Examples

Embodiment 1

[0027] Embodiment 1: for step (1), add 8 times of pure water of spirulina raw material weight, soak time 2h, homogeneous pressure 15MPa, material realizes solid-liquid separation by plate and frame filtration; for step (2), add alkaline protease, alkaline The amount of protease added is 1.0% of the raw material quality of spirulina, which is filtered by ceramic membrane filtration equipment, and the ultrafiltration permeate is concentrated to a solid content of 10% through nanofiltration; for step (3), add alkaline protease and papain, and the amount Respectively 0.6% and 0.2% of the weight of the spirulina raw material, the microfiltration adopts ceramic membrane filtration equipment, and the nanofiltration is concentrated to a solid content of 10%; for step (4) the ultrafiltration concentrate is added to adjust the pH to 2 by adding hydrochloric acid, and the filtered material The pH of the solution was adjusted to 6, and the solid content was concentrated to 10% by nanofiltr...

Embodiment 2

[0035] Embodiment 2: add 10 times of pure water of spirulina raw material weight for step (1), soak time 3h, homogeneous pressure 30MPa, material realizes solid-liquid separation by decanter centrifuge; add neutral protease and papaya for step (2) The amount of protease and neutral protease added is 1.0% of the mass of spirulina raw material, and the amount of papain added is 0.4% of the mass of spirulina raw material. It is filtered by ceramic membrane filtration equipment, and the ultrafiltration permeate is concentrated by nanofiltration to a solid content of 10% %; add neutral protease for step (3), the addition is respectively 0.6% of the spirulina raw material weight, microfiltration adopts diatomite filter, and nanofiltration is concentrated to solid content 12%; for step (4) ultrafiltration Hydrochloric acid was added to the concentrated solution to adjust the pH to 3, the filtered feed solution was adjusted to pH 7, and the solid content was concentrated to 12% by nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com