Force-induced discoloration polyurethane elastomer material as well as preparation method and application thereof

A polyurethane elastomer and color-induced technology, which is applied in the field of mechanochemical conductive materials, can solve the problems of few mechanochromic materials and flexible substrates, the influence of mechanical properties and mechanochromic properties, poor mechanical properties, etc., and achieve rapid color change And reversible, excellent mechanochromic performance, sensitive mechanical force response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of trihydroxyrhodamine derivative:

[0047] The structure of the trihydroxyrhodamine derivative involved in the embodiments of the present invention is shown in formula (3):

[0048]

[0049] The preparation method of above-mentioned trihydroxyrhodamine derivative (referred to as compound 2) is as follows, and its synthetic route is:

[0050]

[0051] The preparation steps of trihydroxyrhodamine derivative (referred to as compound 2):

[0052] (1) Rhodamine 6G (Rhodamine 6G, 10g, 20.8mmol) was dissolved in 160mL of acetonitrile, ethanolamine (3.7mL, 62.6mmol) was added to the solution, the solution was refluxed for 24h and then cooled to room temperature, filtered to obtain a solid, washed with water, vacuum After drying, 9.1 g of off-white product was obtained, and the yield of compound 1 was 95%.

[0053](2) Compound 1 (4g, 8.7mmol) and sodium bicarbonate (9.6g, 69.8mmol) were added to 40mL bromoethanol, and heated at 100°C for 24h. Aft...

Embodiment 1

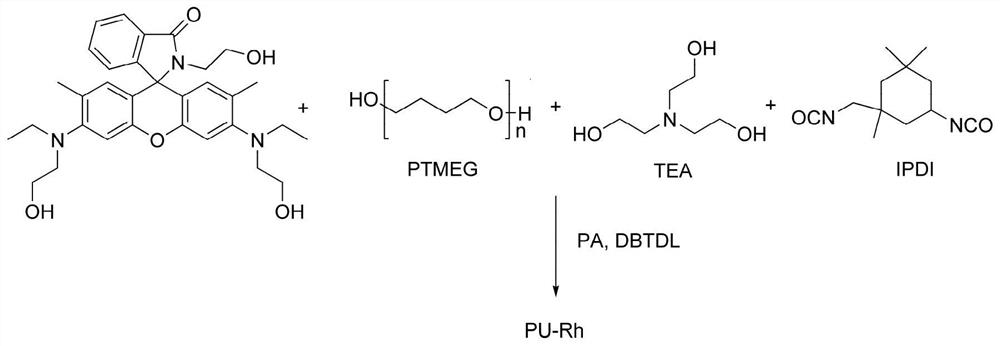

[0064] A method for a mechanochromic polyurethane elastomer material, using polytetrahydrofuran, isophorone diisocyanate, triethanolamine, and trihydroxyrhodamine derivatives as raw materials; figure 1 It is the synthetic route of the mechanochromic polyurethane elastomer PU-Rh of embodiment 1.

[0065] The method comprises the steps in turn:

[0066] Dissolve isophorone diisocyanate (IPDI, 3.508g, 15.8mmol) in acetone (PA), add dibutyltin dilaurate (DBTDL, 30μl) dropwise, heat to 60°C in a round bottom flask, nitrogen Reflux under the protection of the atmosphere, add a trihydroxyrhodamine derivative (0.067 g, 0.1 mmol) dissolved in acetone, and react for 6 hours. Add polytetrahydrofuran (PTMEG, 10g, 11.8mmol) dissolved in acetone and continue the reaction for 6 hours; then add triethanolamine (TEA, 0.399g, 2.7mmol), mix well and pour the product into a polytetrafluoroethylene mold, and wait for the solvent After natural volatilization, the mechanochromic polyurethane film ...

Embodiment 2

[0073] A method for mechanochromic polyurethane elastomer materials, using polytetrahydrofuran, isophorone diisocyanate, and triethanolamine, referring to Example 1, the only difference is that trihydroxyrhodamine derivatives are used as chain extenders to synthesize mechanochromic Color changing polyurethane PU-Rh-1.

[0074] The method comprises the steps in turn:

[0075] Polytetrahydrofuran (PTMEG, 10g, 11.8mmol) was dissolved in acetone (PA), dibutyltin dilaurate (DBTDL, 30μl) was added dropwise, heated to 70°C in a round-bottomed flask, and refluxed under a nitrogen atmosphere. Slowly add isophorone diisocyanate (IPDI, 3.508g, 15.8mmol) dropwise and react for 6 hours to generate a prepolymer. Add trihydroxyrhodamine derivatives (0.067g, 0.1mmol) dissolved in acetone and continue to react for 6 hours; then add triethanolamine (TEA, 0.399g, 2.7mmol), mix well and pour the product into a polytetrafluoroethylene mold , after the solvent volatilized naturally, the mechanoch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com