Continuous electrochemical cyanogen breaking device for cyanogen-containing waste liquid

A cyanide waste liquid and electrochemical technology, which is applied in the field of continuous electrochemical cyanide breaking device for cyanide waste liquid, can solve the problems of short residence time and affect the treatment effect of cyanide, achieve high stability of cyanide breaking, and avoid spray dead angle , Improve the effect of processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

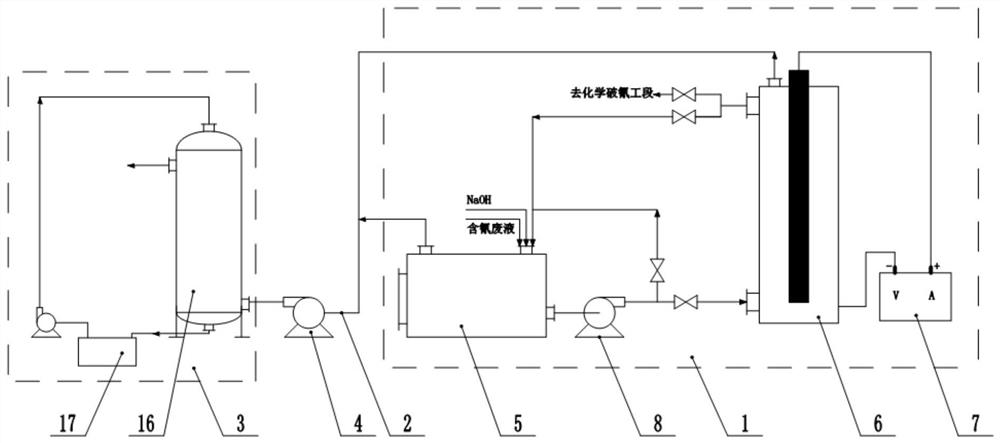

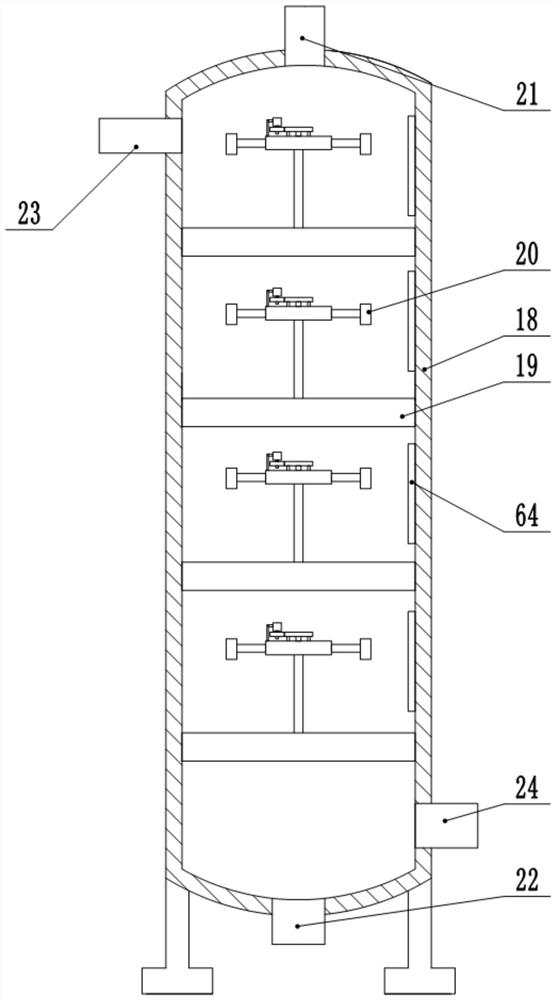

[0044] A continuous electrochemical cyanide breaking device for cyanide-containing waste liquid, including an electric cyanide-breaking system 1 for treating cyanide-containing waste liquid, a tail gas treatment system that communicates with the electric cyanide-breaking system 1 through a delivery pipeline 2 and is used for treating cyanide-containing gas 3. An induced draft fan 4 is installed on the conveying pipeline 2 .

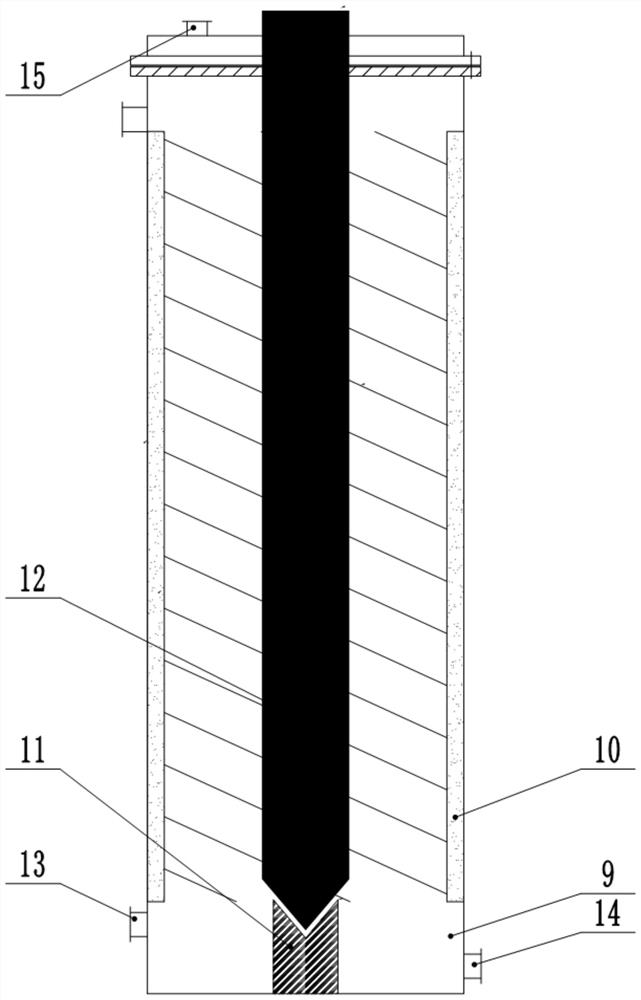

[0045] The electric cyanide breaking system 1 includes a liquid storage tank 5 for temporarily storing cyanide-containing waste liquid, an electric cyanide breaking reactor 6 communicated with the liquid storage tank 5 through a first pipeline, and a rectifier 7 providing electric current for the electric cyanide breaking reactor 6 ; The feeding pump 8 and the first valve are installed on the first pipeline;

[0046] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com