Preparation method of freckle-removing and whitening cosmetic

A freckle whitening, cosmetic technology, applied in the direction of manufacturing tools, material forming presses, presses, etc., can solve the problems of stickiness on the surface of foundation cakes, lowering the quality of foundation cakes, and uneven thickness of foundation cakes, so as to avoid unevenness. , the effect of improving smoothness and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

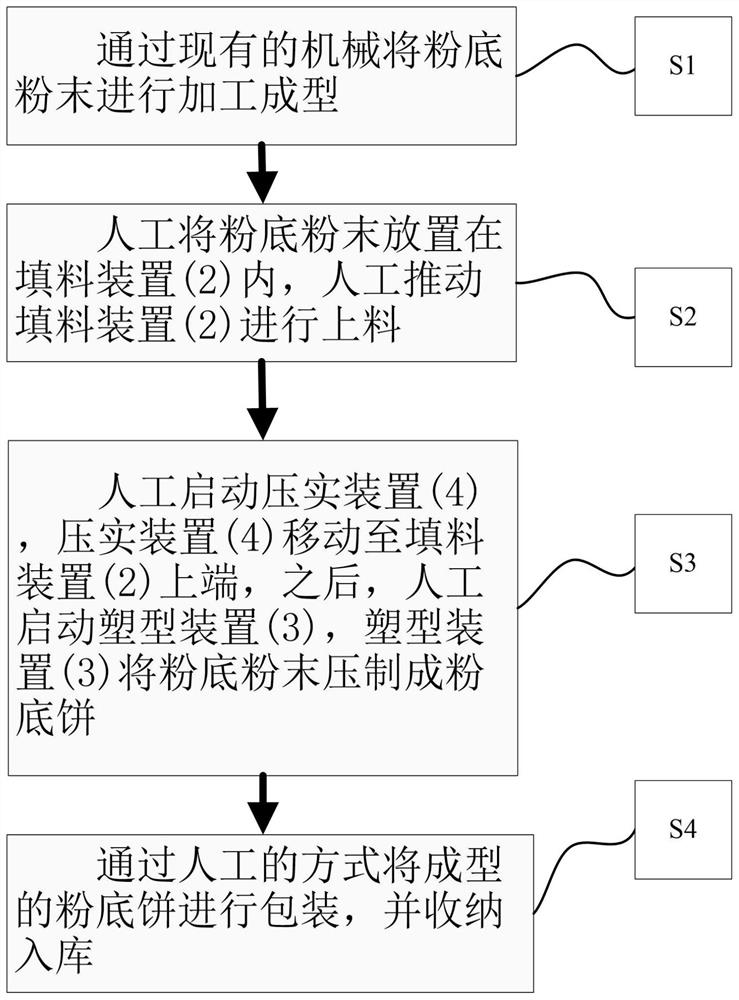

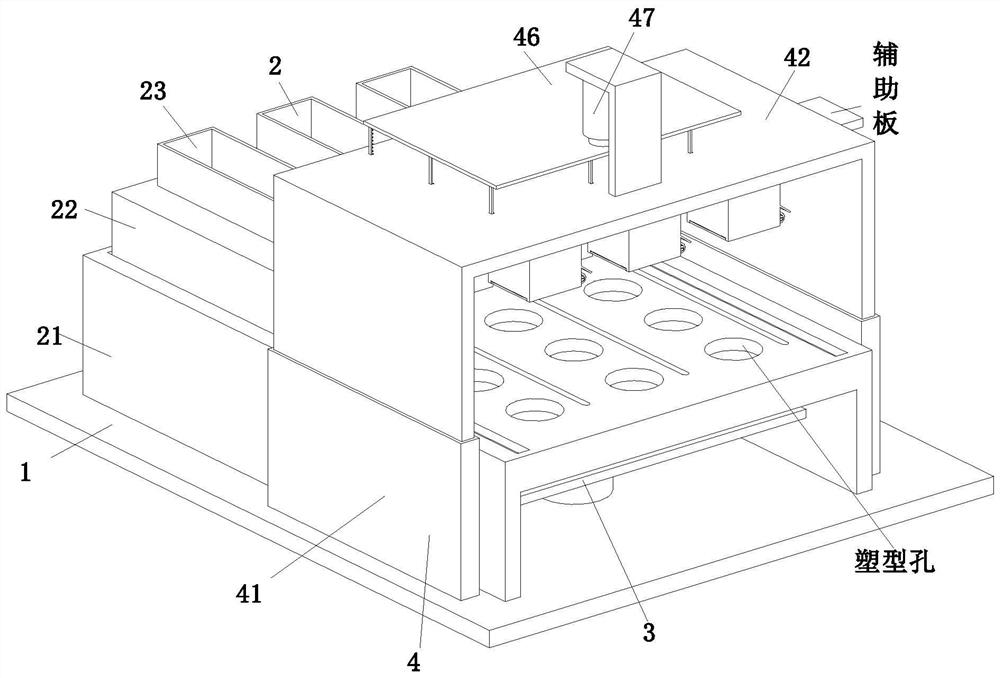

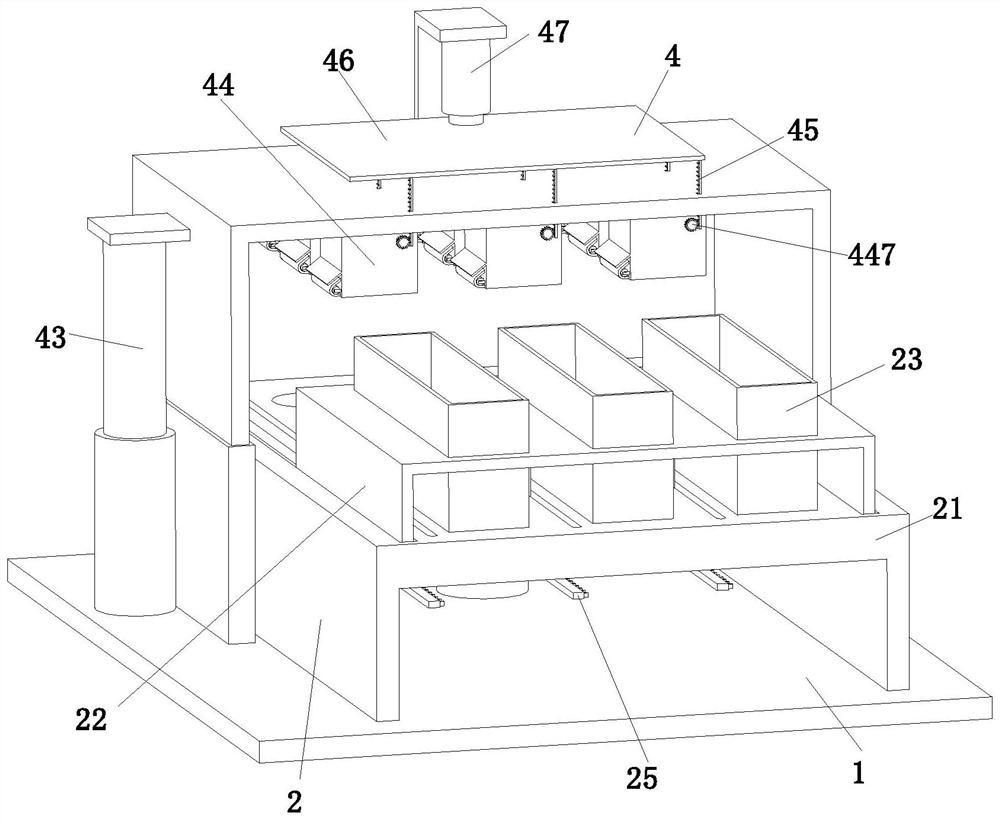

[0037] Such as Figure 1 to Figure 9 As shown, in order to achieve the above object, the present invention adopts the following technical scheme, a preparation method of freckle-removing and whitening cosmetics, which uses a preparation equipment for freckle-removing and whitening cosmetics, and the preparation equipment for freckle-removing and whitening cosmetics includes a base plate 1, a filler device 2, a molding The device 3 and the compacting device 4, when using the freckle-removing and whitening cosmetics preparation equipment to press and shape the foundation cake, the specific method is as follows:

[0038] S1. Foundation production: the foundation powder is processed and shaped by existing machinery;

[0039] S2. Filling preparation: Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com