Novel railway vehicle roof framework

A technology for rail vehicles and skeletons, applied in the field of rail vehicles, can solve the problems of large auxiliary work volume, etc., and achieve the effect of convenient installation and welding, and preventing excessive gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

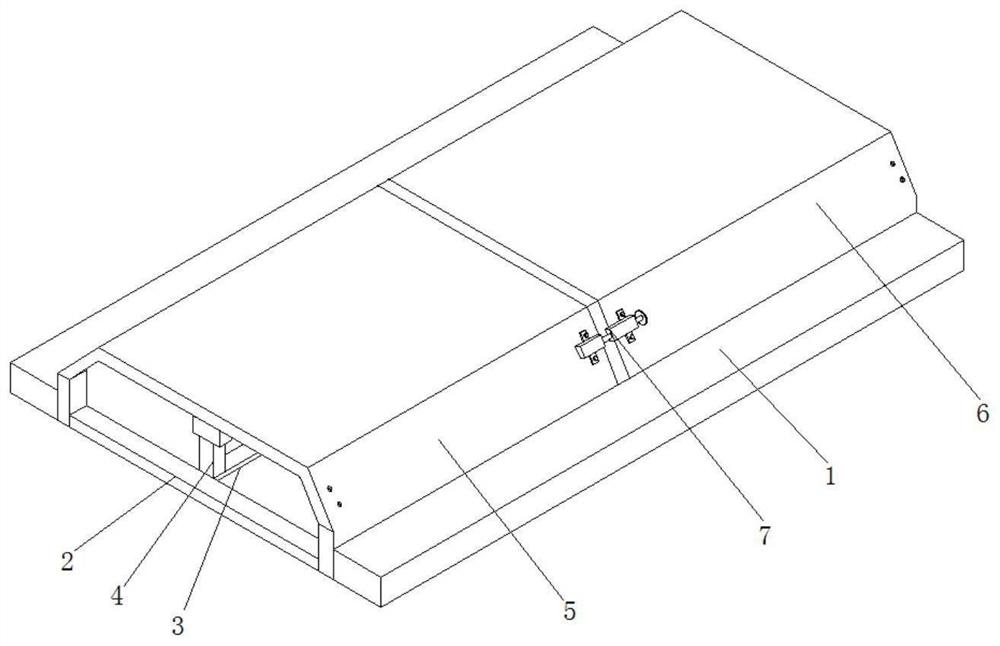

[0026] refer to Figure 1-3 , a new type of rail vehicle roof frame, including two mounting plates 1, the outer walls of the opposite sides of the two mounting plates 1 are fixed with connecting rods 2 through bolts, and the same fixing rod 2 is fixed between the two connecting rods 2 through bolts. Plate 3, the outer walls of the opposite sides of the two mounting plates 1 are fixed with slide rails by bolts, and the inner walls of the two slide rails are respectively slidably connected with the first top plate 5 and the second top plate 6, the first top plate 5 and the second top plate 6 The outer walls on both sides are provided with installation holes, the outer walls on both sides of the first top plate 5 and the second top plate 6 are provided with a connecting mechanism 7, and the support rods 4 are welded on the fixed plate 3. The connecting mechanism 7 includes the first connecting box 8 and the second connecting box. Two connecting boxes 9, the inner walls on both si...

Embodiment 2

[0028] refer to figure 1 , 2 and 4, a new rail vehicle roof frame, including two mounting plates 1, the outer walls of the opposite sides of the two mounting plates 1 are fixed with connecting rods 2 by bolts, and the two connecting rods 2 are fixed by bolts There is the same fixed plate 3, the outer walls of the opposite sides of the two mounting plates 1 are fixed with slide rails by bolts, and the inner walls of the two slide rails are respectively slidably connected with the first top plate 5 and the second top plate 6, the first top plate 5 and the second top plate Both sides outer walls of two top plates 6 are provided with installation holes, first top plate 5 and second top plate 6 both sides outer walls are all provided with connecting mechanism 7, are all welded with support bar 4 on the fixed plate 3, and connecting mechanism 7 comprises the first connection Box 8 and the second connection box 9, the inner walls on both sides of the first connection box 8 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com