An integrated device for automatic cutting and grinding of galvanized pipe fittings

A cutting and pipe fitting technology, used in grinding/polishing safety devices, grinding machines, grinding slides, etc., can solve the problems of scratching construction personnel, low grinding efficiency, affecting the grinding accuracy of incisions, etc. Improve grinding efficiency and improve the effect of docking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

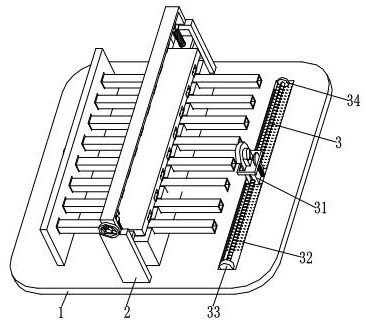

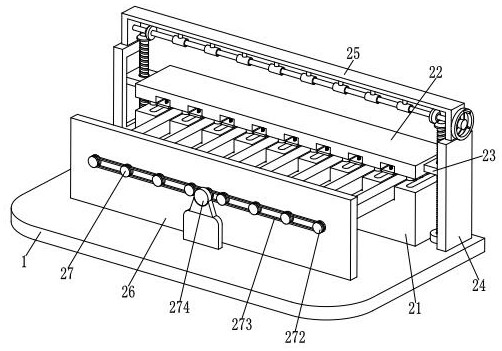

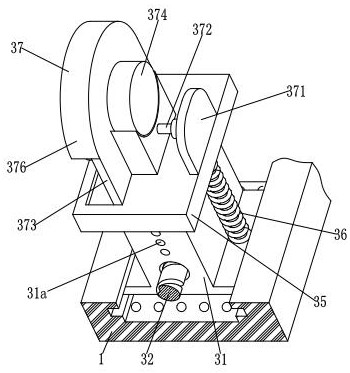

[0028] like Figure 1 to Figure 8As shown in the figure, an integrated device for automatic cutting and grinding of galvanized pipe fittings includes a bottom plate 1, a support locking mechanism 2 and a notch grinding mechanism 3. A support locking mechanism 2 is installed in the middle of the upper end face of the bottom plate 1, which supports locking A notch grinding mechanism 3 is arranged on the right side of the mechanism 2 , and the notch grinding mechanism 3 is installed on the base plate 1 by sliding fit.

[0029] The support locking mechanism 2 includes a placing table 21, a pressing unit 22, a sliding plate 23, a support frame 24, an adjusting locking unit 25, a limit baffle 26 and an inner support unit 27. The upper end surface of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com