Display screen, manufacturing method thereof and electronic equipment with display screen

A production method and technology of electronic equipment, applied in branch office equipment, television, telephone communication, etc., can solve the problems of large through-hole area of camera and small screen-to-body ratio, so as to ensure imaging quality, reduce area, and increase screen-to-body ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

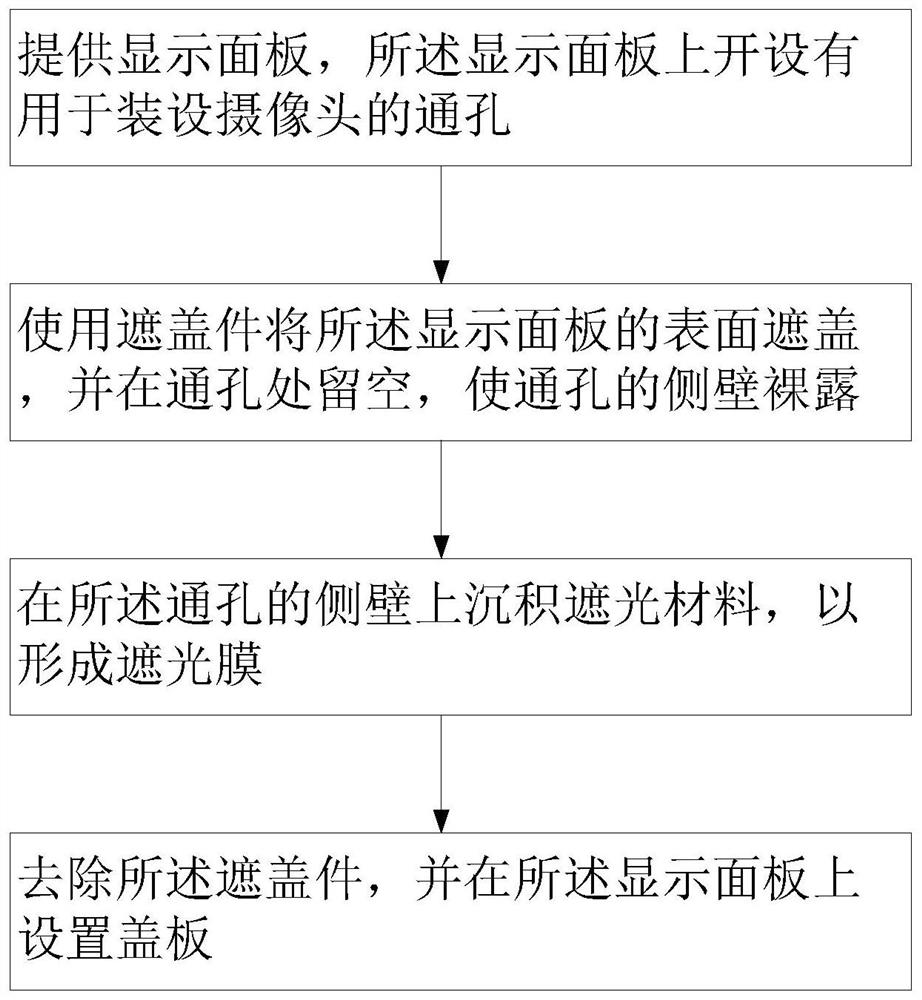

[0058] A display panel 10 is provided, and the display panel 10 is provided with a through hole 11 for installing a camera;

[0059] Covering the surface of the display panel 10 with a mask plate, and leaving a hole at the through hole 11, so that the side wall of the through hole 11 is exposed;

[0060] On the side wall of the through hole 11, the light-shielding material Ti is deposited by PVD sputtering coating method to form a layer with a thickness of The light-shielding film 20, wherein the sputtering target is a Ti target, the power is 10w, the air pressure is 0.3Pa, and the temperature is 25°C;

[0061] The reticle is removed, and a glass cover 30 is disposed on the display panel 10 .

Embodiment 2

[0063] A display panel 10 is provided, and the display panel 10 is provided with a through hole 11 for installing a camera;

[0064] Covering the surface of the display panel 10 with a mask plate, and leaving a hole at the through hole 11, so that the side wall of the through hole 11 is exposed;

[0065] On the side wall of the through hole 11, the light-shielding material W is deposited by PVD sputtering coating method to form a layer with a thickness of The light-shielding film 20, wherein the sputtering target is a W target, the power is 50w, the air pressure is 2.0Pa, and the temperature is 25°C;

[0066] On the surface of the light-shielding film 20 away from the display panel 10, a molybdenum antireflection film 40 with an oxidation thickness of 50 nm is deposited by PVD sputtering coating method, wherein the sputtering target is a molybdenum oxide target, the power is 500w, and the air pressure is 2.0Pa. Temperature 25°C;

[0067] The reticle is removed, and a glass ...

Embodiment 3

[0069] A display panel 10 is provided, and the display panel 10 is provided with a through hole 11 for installing a camera;

[0070] Covering the surface of the display panel 10 with a mask plate, and leaving a hole at the through hole 11, so that the side wall of the through hole 11 is exposed;

[0071] On the side wall of the through hole 11, the light-shielding material MoNb is deposited by PVD sputtering coating method to form a thickness of The light-shielding film 20, wherein the sputtering target is a MoNb target, the power is 50w, the air pressure is 2.0Pa, and the temperature is 25°C;

[0072] The reticle is removed, and a glass cover 30 is disposed on the display panel 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com