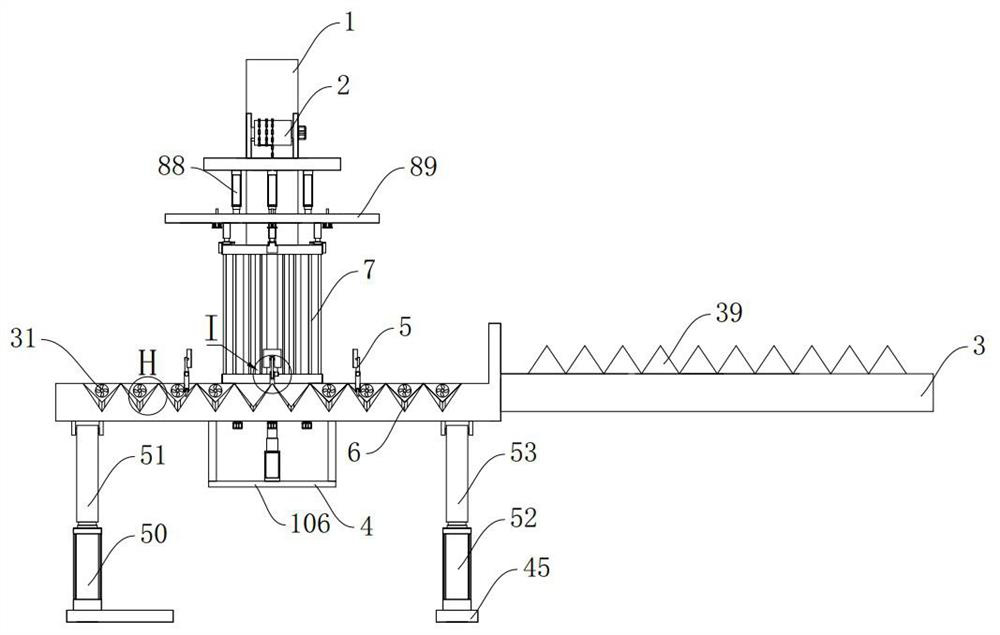

[0004] In view of the above situation, in order to overcome the defects of the prior art, the present invention provides a motor maintenance workbench based on Pascal's law multi-bubble adsorption

impurity removal, which creatively uses the principle of pre-action (adopting the pre-arrangement of relevant equipment at a convenient position, so that It plays a role in time when needed without

wasting time) applied to the motor equipment maintenance workbench equipment, because in the process of motor maintenance, the motor needs to be removed externally, and the old

stator winding coils inside also need to be completely replaced, which takes a long time The

metal rust fragments accumulated on the outside of the motor and the

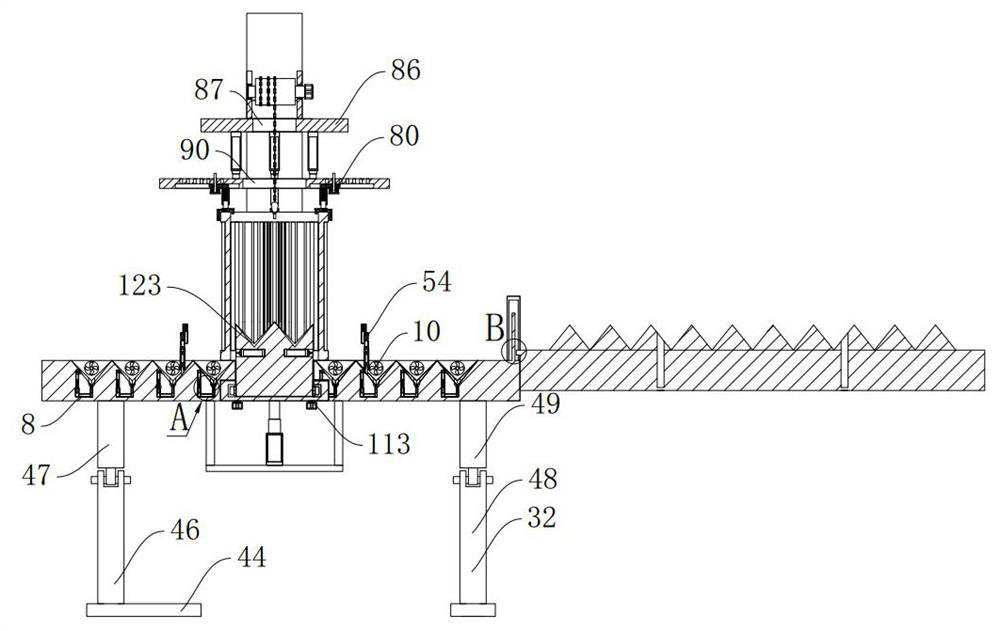

metal debris falling during the dismantling process need to be collected to prevent debris and other substances from accumulating in the maintenance area and avoid affecting the subsequent maintenance operations of the motor equipment. The table is changed into two sets of splicing panels with V-shaped sawtooth-shaped snap-on blocks, which can be used to choose the horizontal table

placement method according to the operation steps of the current motor maintenance, and can be effectively collected through the V-shaped snap-in groove

Metal scraps and metal

scrap wires of the

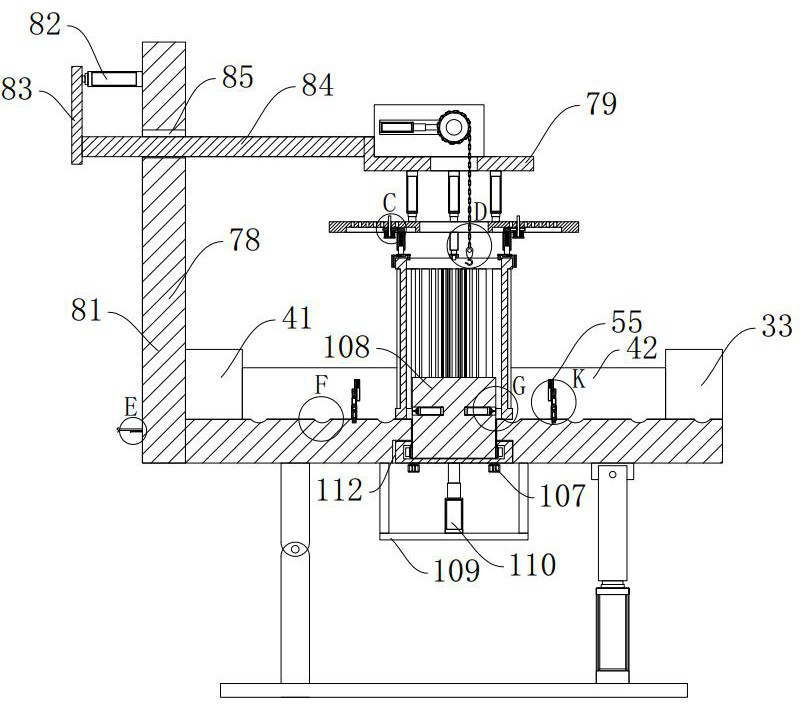

stator winding, the edge of the V-shaped sawtooth support block can effectively support the motor, and will not affect the operation steps of the motor maintenance; creatively apply Pascal's law (incompressible static fluid After any point is subjected to an external force to generate a

pressure increase, the

pressure increase is transmitted to each point of the static fluid instantaneously) and is used in the cleaning process of debris. According to the characteristics of the increasing number of

falling objects during the maintenance process, combined with deep groove waste The object support plate moves down automatically to realize the technical effect of

fully automatic bubble-type adhesion and impurity removal. One end of the

partial pressure balance device is constantly under the pressure of debris accumulated on the upper end, and the original balance state of the bottom end of the

partial pressure balance device changes. As the

hydraulic pressure at one end of the

partial pressure balance device rises, in order to release the pressure, the height of the other end of the bottom partial

pressure balance device changes. By constantly stirring the easy-to-foam solution and adjusting the liquid level of the foam solution, foaming can be easily achieved. The design goal of the contact between the solution and the debris substance; creatively use the easy-to-foam material to change the morphological structure of the adsorbed substance (change the liquid

aqueous solution into a foam-type

aqueous solution structure) to adsorb impurities, due to the motor during maintenance. A large amount of debris and other tiny particles or substances, ordinary brushing and wind blowing will cause harmful substances to splash, making the table more messy, and directly using a large amount of running water to wash will cause waste of

water resources. In order to reduce

water resources Therefore, the traditional cleaning method is replaced by a foaming solution, which not only retains the

adsorption effect of the

surface tension of the liquid on impurities, but also increases the adsorption area of the liquid and expands the working area of the adsorption; creatively uses non-

Newtonian fluid materials (subjected suddenly from The

external pressure will be stabilized instantly) applied in the device, in the process of motor maintenance, if the motor is unbalanced when the

stator winding is removed, the motor will swing for a moment, and once the position of the motor deviates, it must be reinstalled. The positioning operation is convenient for the user to remove the stator winding in the next step. Therefore, the use of a fixing device with a non-

Newtonian fluid can not only effectively move the non-Newtonian fluid along the

convex structure outside the motor when the motor is fixed in a limited position. snapping, in turn able to occur in the motor When deflecting instantaneously, the non-Newtonian fluid is stable and no longer flows, effectively fixing the outside of the motor to ensure that the motor is always in a fixed operating position for maintenance, which effectively solves the current workbench for removing old coils in motor maintenance on the market Low efficiency, complex structure and inconvenient maintenance

Login to View More

Login to View More  Login to View More

Login to View More