An intelligent welding machine for metal pressure vessels

A pressure vessel and intelligent technology, applied in the field of intelligent welding machines for metal pressure vessels, can solve the problems of reducing welding efficiency and welding quality, and the situation is not easy to observe and detect, so as to improve welding efficiency and welding quality, improve welding quality and improve welding quality. Economic benefits, improved real-time and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

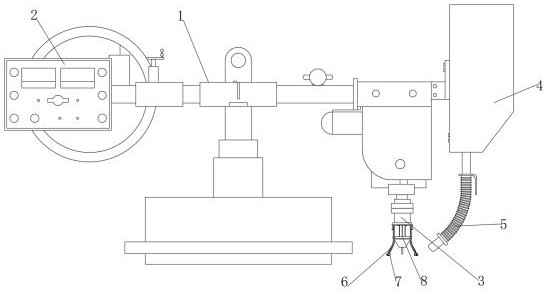

[0047] see Figure 1-10 , an intelligent welding machine for metal pressure vessels, an intelligent welding machine for metal pressure vessels, including an intelligent submerged arc welding machine body 1, and a welding control device installed on the left side of the intelligent submerged arc welding machine body 1 Box 2 and the submerged arc welding machine head 3 installed on the right side of the intelligent submerged arc welding machine body 1, the submerged arc welding machine head 3 is electrically connected to the welding control box 2 through wires, please refer to figure 1 The right end of the body 1 of the intelligent submerged arc welding machine is equipped with a flux box 4 matching the head 3 of the submerged arc welding machine. An electric control valve is installed on it, and the electric control valve is electrically connected with the welding control box 2 through wires. The welding control box 2 controls the submerged arc welding machine head 3, the flux...

Embodiment 2

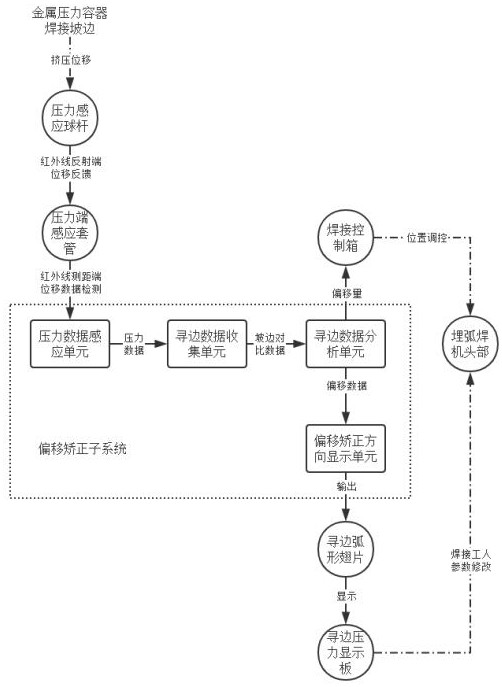

[0050] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 , the edge-finding sensing bollard 701 is provided with an offset correction subsystem, the offset correction subsystem includes an edge-finding data analysis unit, the input end of the edge-finding data analysis unit is connected to an edge-finding data collection unit, and the edge-finding data collection unit inputs The end is connected with a pressure data sensing unit, the output end of the edge-seeking data analysis unit is connected with an offset correction direction display unit, the output end of the edge-finding data analysis unit is electrically connected with the welding control box 2 through wires, and acts on the submerged arc we...

Embodiment 3

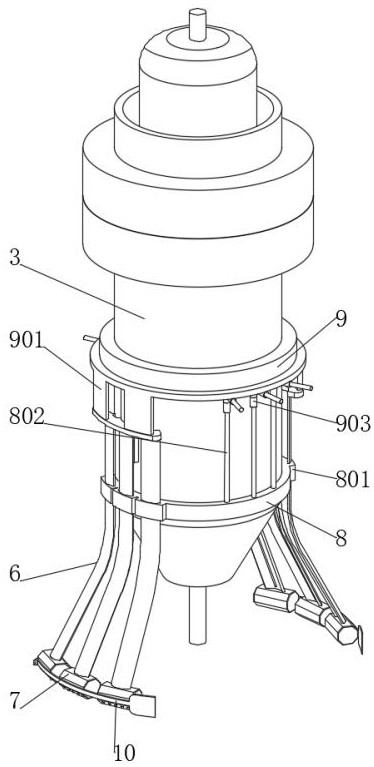

[0052] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 3-5 , the outer end of the submerged arc welding machine head 3 is fixedly connected with a guide adjustment ring 8 located on the lower side of the vertical limit ring 9, and the left and right ends of the guide adjustment ring 8 are fixedly connected with guide arcs 801, and the edge-seeking arc fins 6 runs through the guide arc 801 and is slidably connected with it. The guide arc 801 can limit and guide multiple edge-seeking arc-shaped fins 6, and when the edge-seeking arc-shaped fins 6 move vertically and straightly, the movement accuracy can be improved, and the displacement of the edge-seeking arc-shaped fins 6 can be improved. The adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com