Preparation method for one-dimensional metallic oxide nano needle material

A technology of nano needles and oxides, which is applied in the field of nano materials and nano, which can solve the problems of high equipment requirements, restrictions on the application of one-dimensional metal oxide nano materials, and high synthesis costs, and achieve high controllability, low cost, and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

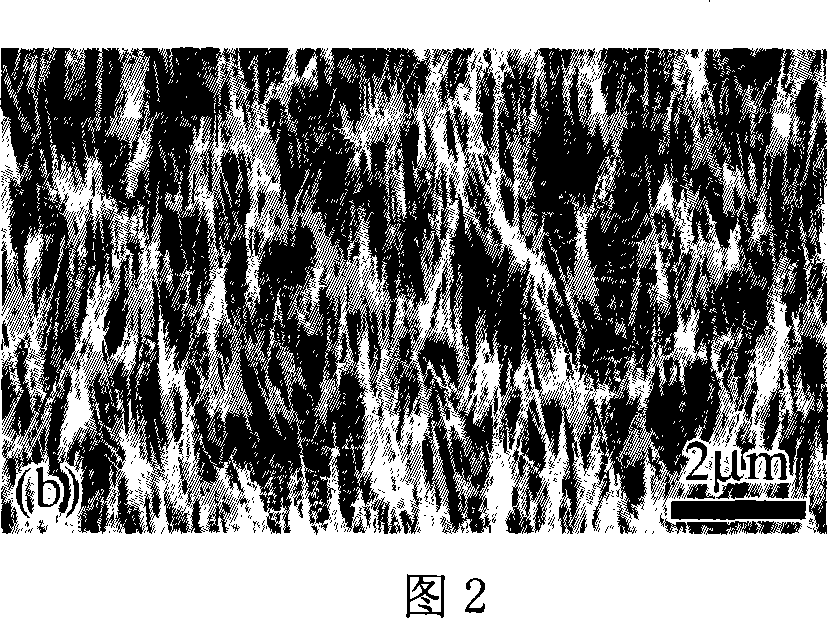

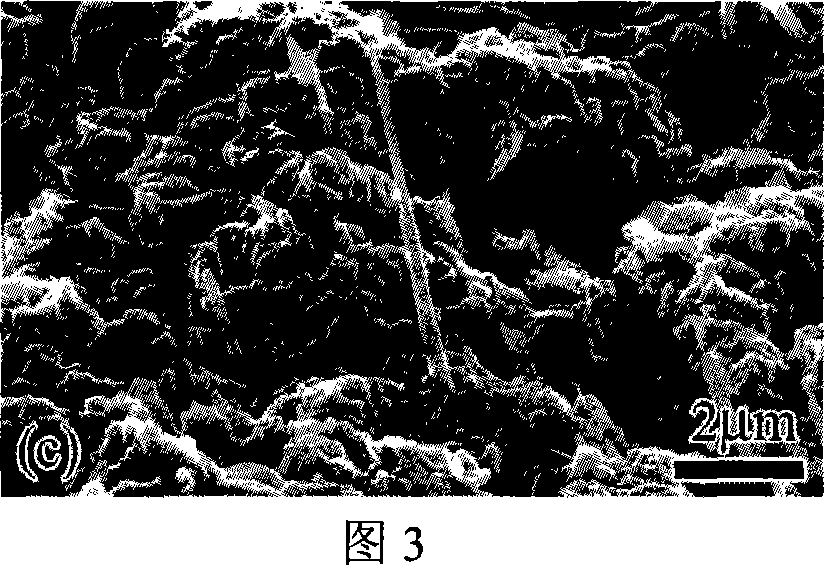

[0012] Example 1: Preparation of one-dimensional CuO nanoneedle material

[0013] (1) The pH of the preparation is 1.0, and the concentration of each component is copper sulfate 210gl -1 , boric acid 45gl -1 , saccharin 5gl -1 , sodium fluoride 0.5gl -1 (2) Using the pulse electrodeposition method, the pulse electrodeposition parameters: the output pulse frequency f is 100Hz, the duty ratio r is 10%, the positive pulse working current is 0.5A, and the negative pulse working current is 0.3A. Electrodeposit a layer of nanocrystalline Cu film on the surface of the substrate; (3) Heat the nanocrystalline Cu film in air at 700°C, 800°C, 900°C, and 1000°C for 1 to 2 hours, and thermally oxidize it to obtain a one-dimensional CuO nanometer Needle.

[0014] The scanning electron microscope SEM photos of each product obtained are shown in Figure 1, Figure 2, Figure 3, and Figure 4. Figure 1, Figure 2, Figure 3, and Figure 4 are respectively when the thermal oxidation temperature is...

Embodiment 2

[0015] Example 2: Preparation of one-dimensional ZnO nanoneedle material

[0016] (1) The pH value of the preparation is 5.0, and the concentration of each component is zinc chloride 100gl -1 , potassium chloride 160gl -1 , boric acid 30gl -1 , saccharin 5gl -1 (2) Using the pulse electrodeposition method, the pulse electrodeposition parameters: the output pulse frequency f is 100Hz, the duty ratio r is 10%, the positive pulse working current is 0.5A, and the negative pulse working current is 0.3A. Electrodeposit a layer of nanocrystalline Zn film on the surface of the substrate; (3) Heat the nanocrystalline Zn film in air at 300°C, 400°C, 500°C, and 600°C for 1 to 2 hours, and thermally oxidize to obtain a one-dimensional ZnO nanometer film. Needle.

[0017] The scanning electron microscope SEM photos of each product obtained are shown in Figure 5, Figure 6, Figure 7, and Figure 8. Figure 5, Figure 6, Figure 7, and Figure 8 are respectively when the thermal oxidation temp...

Embodiment 3

[0018] Example 3: Preparation of one-dimensional γ-Fe 2 o 3 nanoneedle material

[0019] (1) The pH value of the preparation is 2.0, and the concentration of each component is ferrous chloride 380gl -1 , boric acid 20gl -1 , saccharin 5gl -1 , sodium fluoride 2.5gl -1 (2) Using the pulse electrodeposition method, the pulse electrodeposition parameters: the output pulse frequency f is 100Hz, the duty ratio r is 10%, the positive pulse working current is 0.5A, and the negative pulse working current is 0.3A. Electrodeposit a layer of nanocrystalline Fe film on the surface of the substrate; (3) Heat the nanocrystalline Fe film in air at 700°C, 800°C, and 900°C for 1 to 2 hours, and thermally oxidize it to obtain one-dimensional γ-Fe 2 o 3 nanoneedles.

[0020] The scanning electron microscope SEM pictures of each obtained product are shown in Figure 9, Figure 10, and Figure 11. Figure 9, Figure 10, and Figure 11 are products when the thermal oxidation temperature is 700°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com