High-permeability selective acid-resistant nanofiltration membrane material as well as preparation method and application thereof

A selective, nanofiltration membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of polluted environment, high energy consumption, low permeation selectivity, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

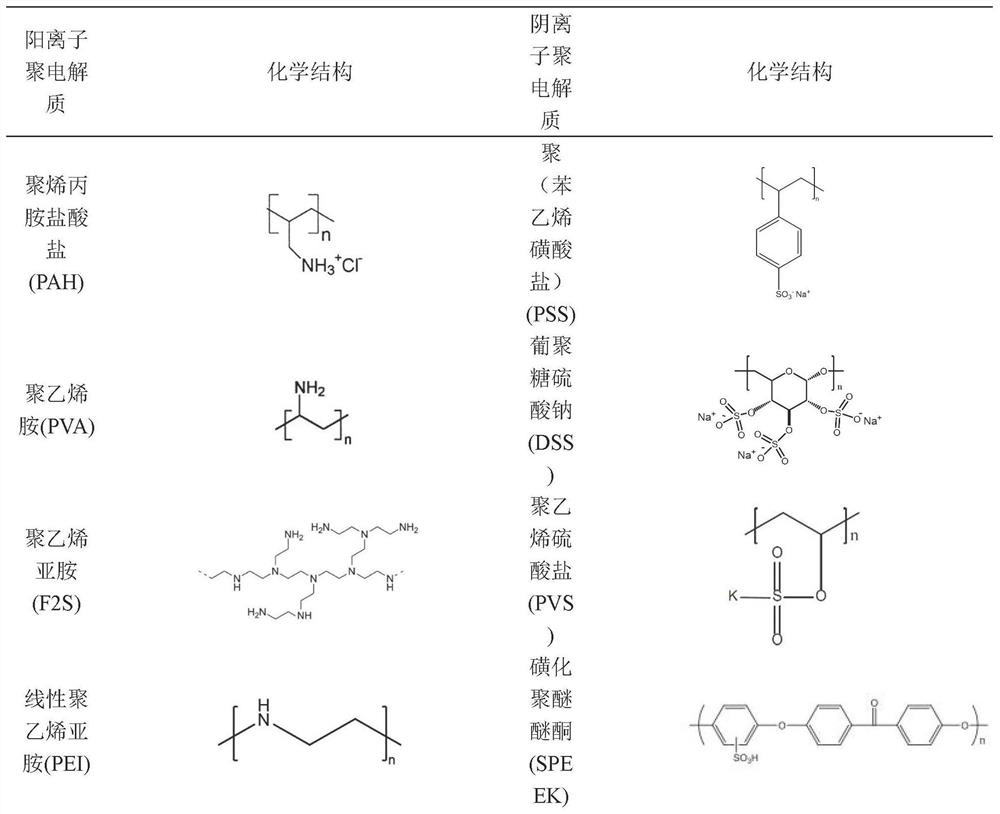

Method used

Image

Examples

Embodiment 1

[0035] A hollow fiber polysulfone base membrane was selected, MWCO=50k Da. First, the basement membrane was washed with deionized water for 1 h, and gas was purged for 1 min. The polycation electrolyte 5g / L PEI (MWCO=100k Da) dissolved in 1.5mol / L NaCl solution and the polyanion electrolyte 5g / L PSS (100k Da) dissolved in 1.5mol / L NaCl solution were alternately coated in the base film Hole, stay for 10 minutes; first coat PEI; after each layer is coated, wash with deionized water for 5 minutes, and gas purge for 1 minute; after coating 3 double layers, use 0.5wt. Rinse with water for 5 minutes and store in refrigerator or deionized water. Prepared membrane material test 500ppm magnesium chloride flux J and rejection rate R, J=17.2LMHbar, R=97.3%; filter 10% H 3 PO 4 +2g / L Al simulated phosphoric acid solution, test phosphoric acid flux Flux, Al rejection rate R Al and phosphoric acid permeability P p , Flux=3.42LMHbar, R Al =98.2%, P p = 94.1%. The prepared film was ch...

Embodiment 2

[0037] The same as the membrane-making method in Example 1, the polyanion electrolyte in Example 1 was replaced by a 5 g / L SPEEK (sulfonation degree of 70%) aqueous solution. Prepared membrane material test 500ppm magnesium chloride, J=15.2LMHbar, R=97.5%; filter 10% H 3 PO 4 +2g / L Al simulated phosphoric acid solution, Flux=3.05LMHbar, R Al =98.5%, P p = 91.7%.

Embodiment 3

[0039] The same as the membrane-making method in Example 1, the polyanion electrolyte in Example 1 was replaced by 5g / L PVS (200k Da) dissolved in 1.5mol / L NaCl solution. Prepared membrane material test 500ppm magnesium chloride, J=18.9LMHbar, R=96.7%; filter 10%H 3 PO 4 +2g / L Al simulated phosphoric acid solution, Flux=3.55LMHbar, R Al =97.1%, P p = 93.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com