A method of synthesizing graphene felts without using binders

A technology for synthesizing graphite and graphite felt, which is used in the fields of synthetic graphite felt, synthesis/preparation of graphite felt, processing of graphene materials, synthesis of graphite felt without binder, support and mechanical strength, and can solve the problem of affecting graphite felt. Electrochemical, catalytic and sensing properties, graphite felt properties and performance effects, affecting the conductivity of graphite felt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the following detailed description, reference is made to the accompanying drawings, which form a part hereof, and in which are shown by way of illustration specific embodiments that may be practiced. These embodiments are described in sufficient detail to enable those skilled in the art to practice them, it being noted that other changes may be made without departing from the scope of these embodiments. Accordingly, the following detailed description should not be viewed as limiting.

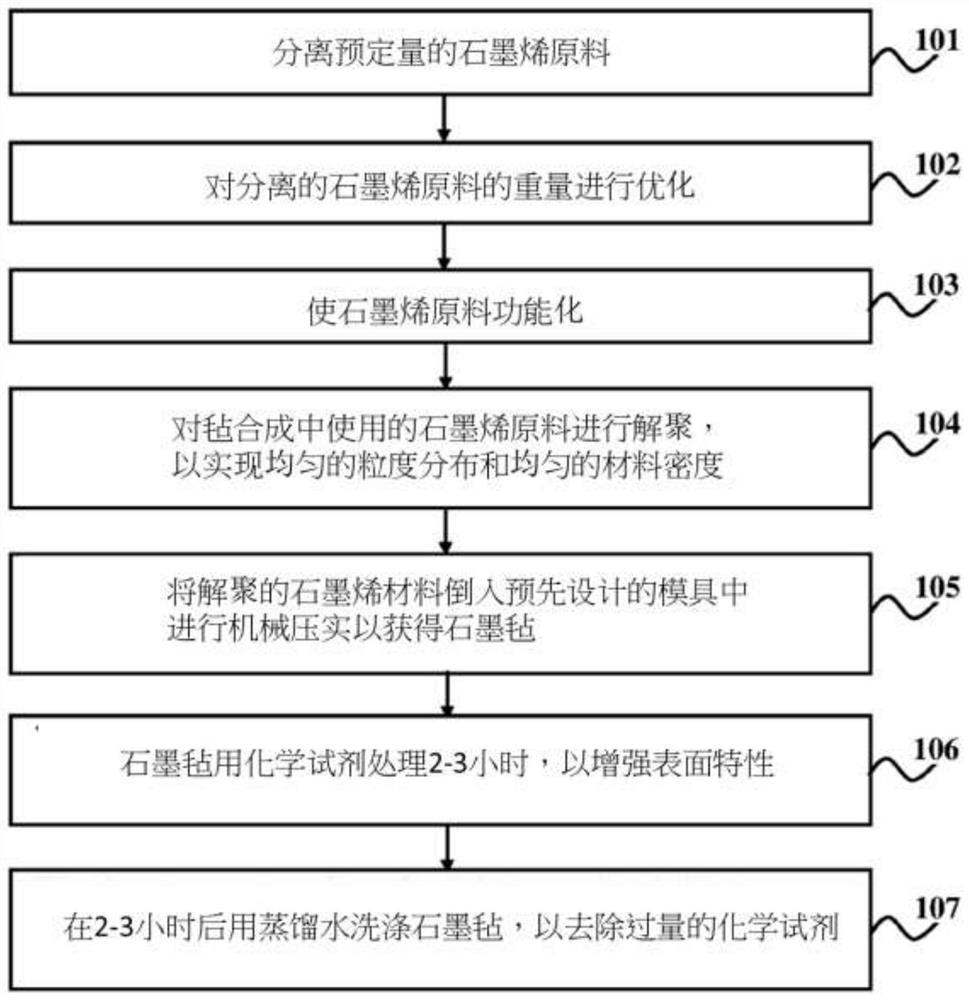

[0050] Various embodiments of the present invention provide a method of synthesizing graphite felt without the use of binders.

[0051] According to an embodiment of the present invention, a method for preparing / synthesizing binder-free graphite felt is provided, and wherein the graphene material is selected from graphene sheets, graphene ribbons, graphene flakes, graphene foams, graphene sponges, The group consisting of graphene airgel, graphene 3D structure, highly expanded graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com