A plunger pump power control device and control method thereof

A technology of power control and plunger pump, which is applied in the direction of pump control, liquid variable displacement machinery, machine/engine, etc., can solve the problems of variable variable jamming, etc., and achieve the effect of variable variable, simple structure, and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (Example 1, a plunger pump power control device)

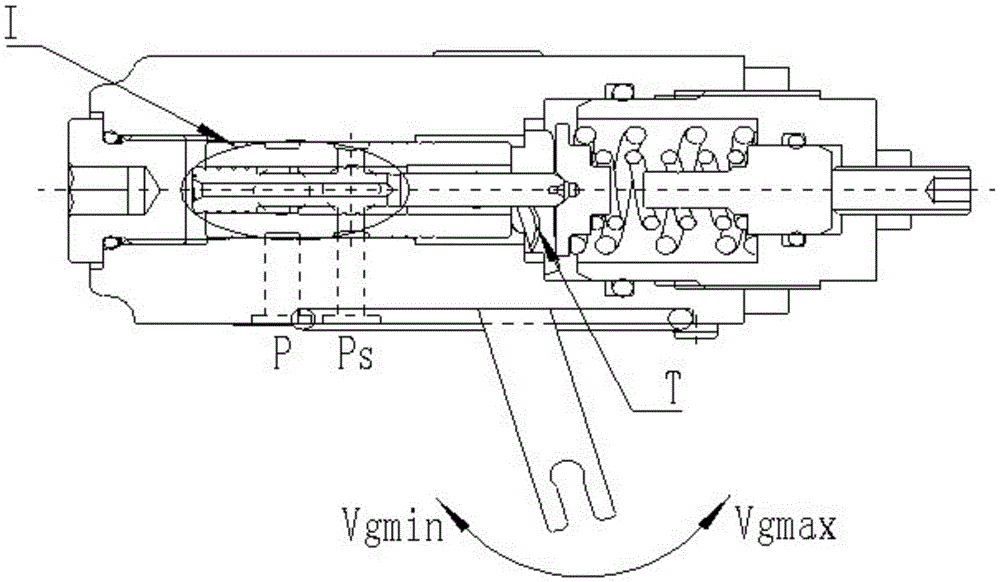

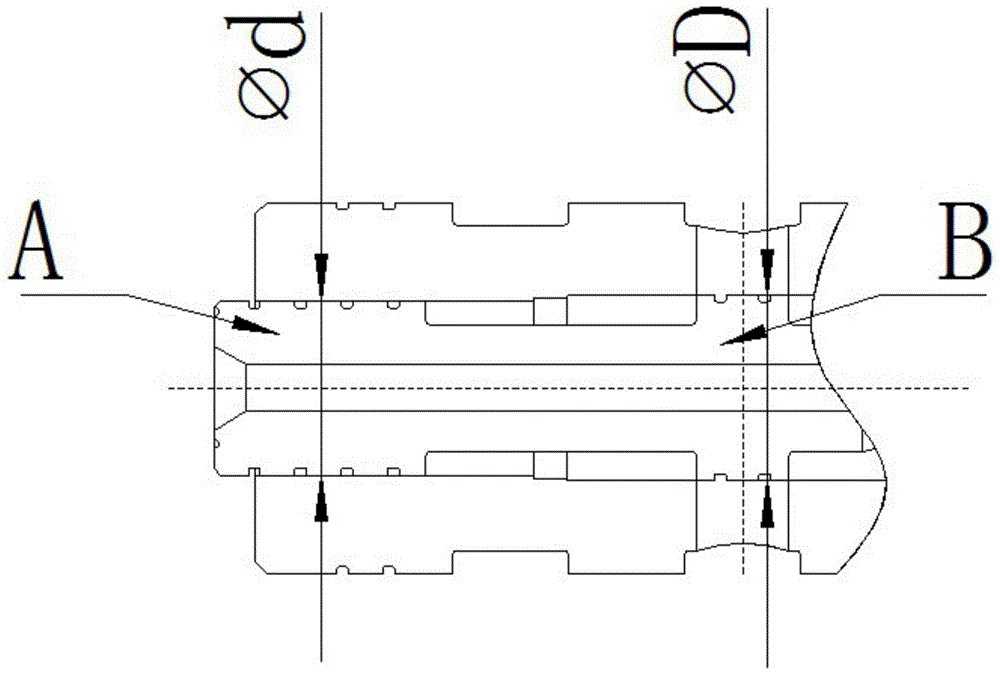

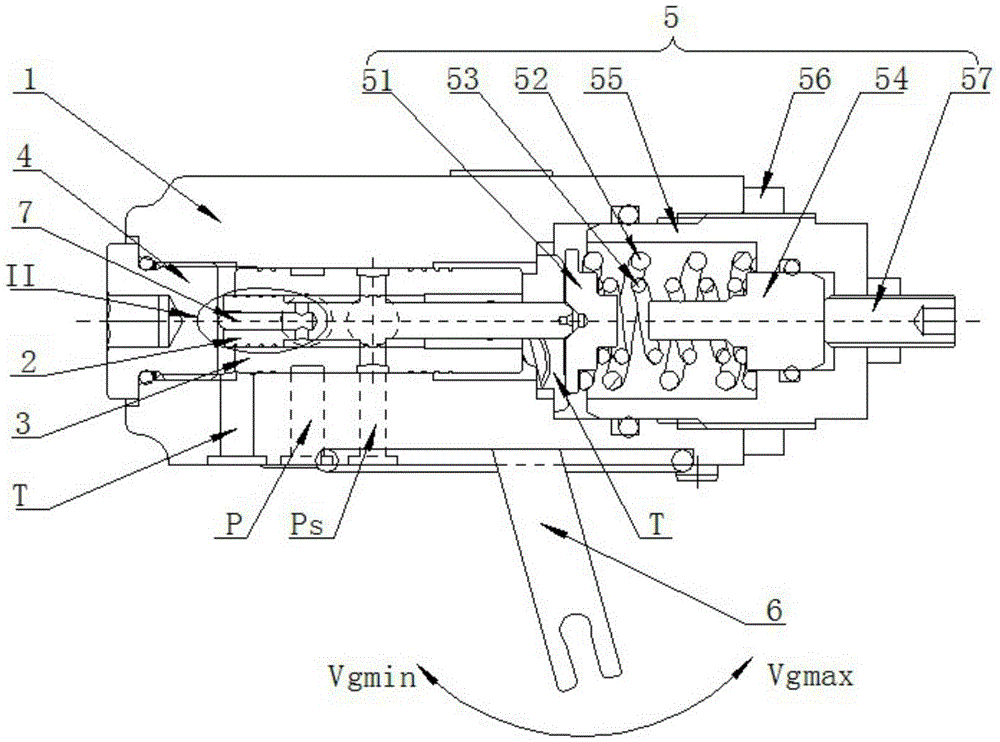

[0030] See Figure 3 to Figure 5 , a plunger pump power control device, with a control valve body 1, a valve core 2, a valve sleeve 3, a stop screw plug 4, a spring preload mechanism 5, a feedback mechanism 6 and a slide valve 7; the control valve body 1 is provided with There are oil inlet P, oil outlet Ps and two oil discharge ports T; the oil outlet Ps is externally connected to the variable piston chamber of the pump body; the valve core 2 is set in the valve sleeve 3, and the valve sleeve 3 and the valve core 2 form a 3-position 2-way structure valve, the E chamber is formed between the valve sleeve 3 and the valve core 2; the slide valve 7 is arranged at the center of one end of the valve core 2, and the slide valve 7 and the valve core 2 form a C cavity in the radial direction of the valve core 2, and the slide valve 7 The ball end of the ball is in contact with the stop screw plug 4; the stop screw plug 4 is se...

Embodiment 2

[0035] (Example 2, a control method for a plunger pump power control device)

[0036] A control method for a plunger pump power control device, the specific steps are as follows:

[0037] ① Set the value of the spring preload mechanism 5;

[0038]②Introduce the pressure oil at the pump outlet from the oil inlet P, and enter the cavity C of the valve core 2 through the valve sleeve 3. The pressure oil at the pump outlet pushes the slide valve 7 and the valve core 2 to move in the opposite direction, and the slide valve is stopped by the stop screw. If it is blocked, the spool moves to the compression spring preloading mechanism; or the pressure of oil inlet P decreases, and the spring preloading mechanism pushes the spool to move in the opposite direction against the pressure of cavity C;

[0039] ③ Perform binary processing, when the outlet pressure of the pump introduced into chamber C increases and exceeds the value set by the spring preload mechanism 5, the spool 2 moves i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com