A seamless bridge structure and construction method based on ultra-high toughness cement-based composite materials

A composite material and seamless bridge technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as stress cracking in negative bending moment areas, achieve the effects of improving stress conditions, improving earthquake resistance, and enhancing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

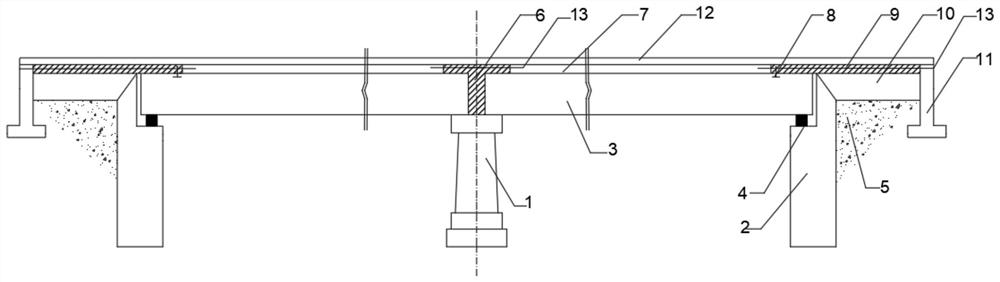

[0056] A seamless bridge structure based on ultra-high toughness cement-based composite materials, taking a bridge with a total span of 20m as an example, such as figure 1 As shown, it includes bridge pier 1, bridge abutment 2, main beam 3, T-shaped connecting member 6, ECC connecting plate 9 and cantilevered ground beam 11;

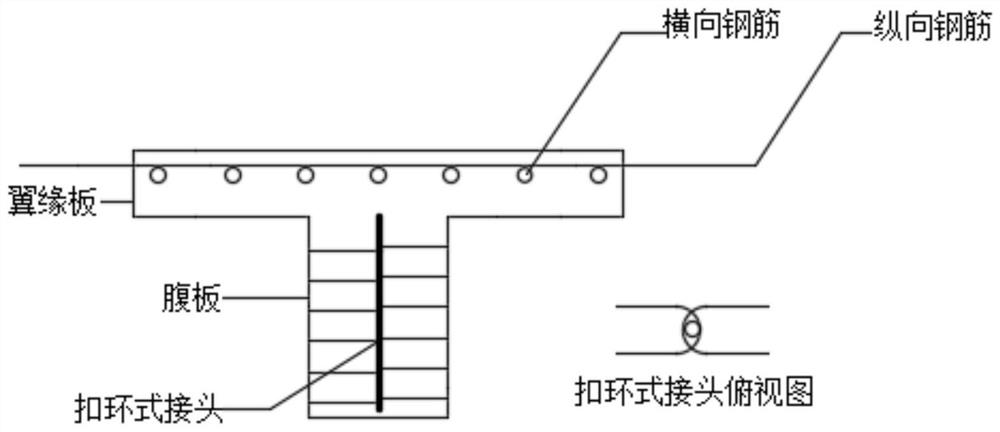

[0057] A T-shaped connecting member 6 of ECC material is cast in place at the gap between two adjacent main beams 3 . The cross-sectional structure of the ECC material T-type connecting member 6 is as follows: figure 2 As shown, the T-shaped connecting member 6 is composed of a web plate and a flange plate. The flange plate is the horizontal horizontal part of the T-shaped and is located on the upper surface of the main beam 3; At the gap between the main beams 3; in the flange plate, the reinforcement is respectively reinforced along the longitudinal and lateral directions of the bridge to form a steel mesh; the length of the longitudinal reinforcemen...

Embodiment 2

[0074] A construction method for a seamless bridge structure based on ultra-high toughness cement-based composite materials (that is, the seamless bridge structure in Embodiment 1), comprising the steps of:

[0075] 1. Prepare steel, concrete, ECC and other materials, of which the ECC ratio per cubic meter is: water 325kg / m 3 , cement 568kg / m 3 , fly ash 682kg / m 3 , quartz sand 455kg / m 3 , polycarboxylate superplasticizer 10kg / m 3 , hydroxypropyl methylcellulose thickener 0.57kg / m 3 , Japan Kuraray PVA fiber 26kg / m 3 . Cast-in-place foundation, pier 1, abutment 2 and other structures;

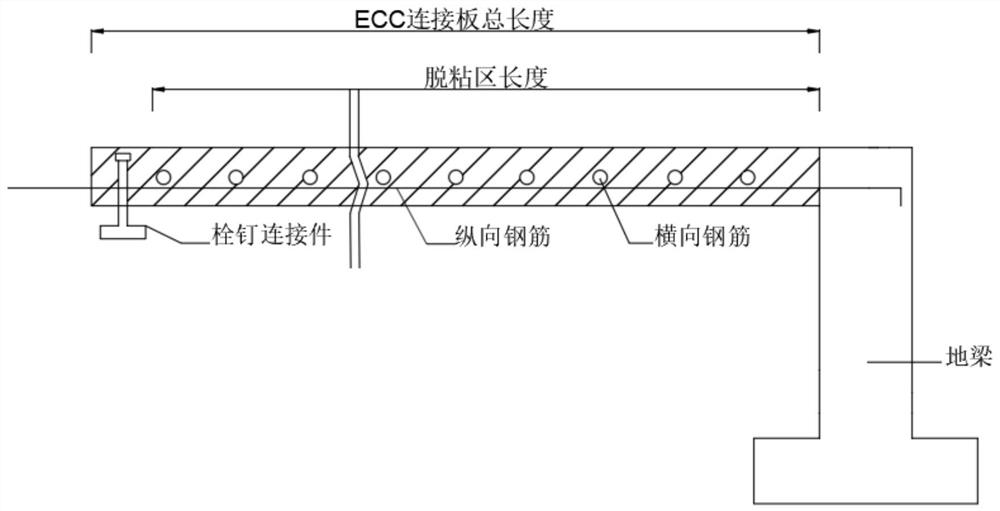

[0076] 2. Prefabricate the main beam 3 and preset the stud connector 8 and the anchoring steel bar;

[0077] ① Pre-set U-shaped steel bars at the junction of the beam ends of the main beams 3 of different spans to connect the main beams 3 of different spans to complete the system conversion from simply supported beams to continuous beams;

[0078] ② In advance, fix a row of stud connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com