System for preparing hydrogen-rich synthesis gas through biomass grading gasification

A biomass and synthesis gas technology, which is applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of unfavorable upgrading, low calorific value of gas production, restricted promotion and application, etc., so as to improve the economy of carbon atom utilization. performance, achieve self-sustaining process heat, and good technical and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

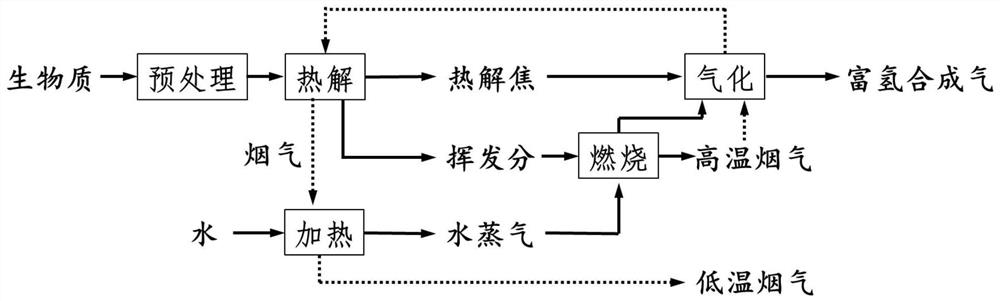

[0020] Such as figure 1 As shown, a system for producing hydrogen-rich synthesis gas by staged biomass gasification designed in the present invention includes a biomass pretreatment unit, a pyrolysis reaction device, a gasification device, a volatile matter combustion unit and a heat exchange unit.

[0021] The biomass described in this embodiment specifically includes wheat straw, rice straw, cotton stalk, sawdust, etc., but is not limited to the above-mentioned biomass materials.

[0022] Biomass pretreatment unit is used for crushing and forming pretreatment of biomass to obtain shaped biomass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com