Pyrolysis and catalytic pyrolysis method for infrared rapid heating of waste plastics

A technology for waste plastics and catalytic pyrolysis, which is used in the heating of coke ovens, special forms of dry distillation, coke ovens, etc. The effect of improving quality and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

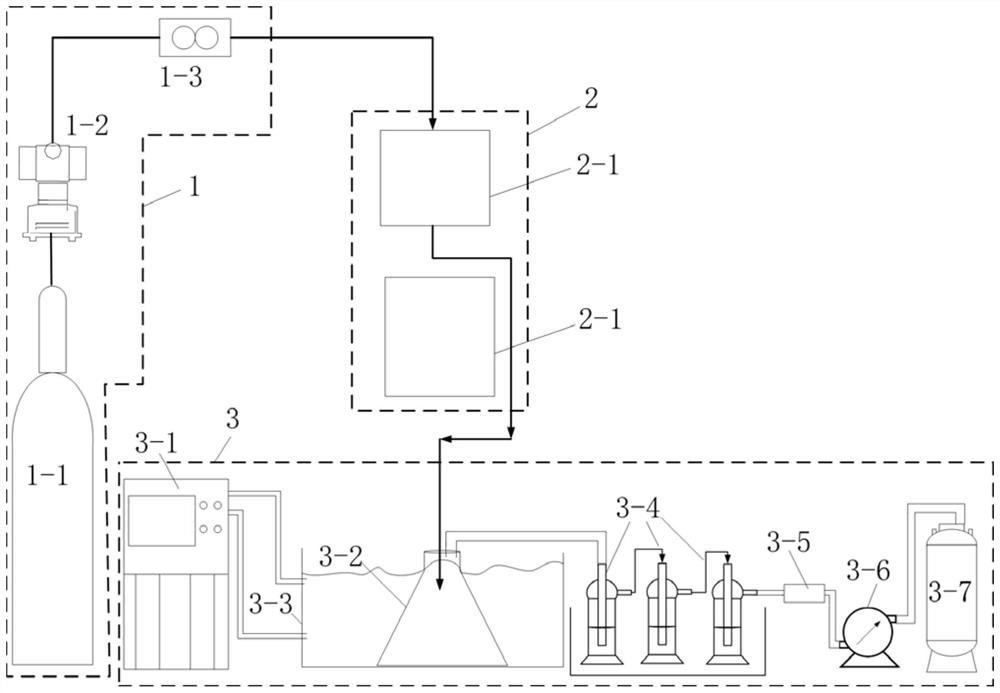

[0035] Such as figure 1 As shown, the infrared heating waste plastics pyrolysis and catalytic pyrolysis method of the present invention is the process equipment for separate pyrolysis of waste plastics. The components include a gas distribution system 1 , a pyrolysis reactor 2 and a product recovery system 4 . The specific structure and connection relationship of the components are:

[0036] The gas distribution system 1 includes a high-pressure steel cylinder 1-1, a gas pressure reducing valve 1-2 and a high-pressure steel cylinder 1-3, which are connected by stainless steel pipes or copper pipes with an inner diameter of 3mm, and the high-pressure steel cylinder 1-1 is first connected to the gas Pressure reducing valve 1-2, gas pressure reducing valve 1-2 is connected with high-pressure steel cylinder 1-3 again, and high-pressure steel cylinder 1-3 is connected with pyrolysis reactor 2;

[0037] The product recovery system 4 includes a refrigerator 4-1, a liquid collection ...

Embodiment 2

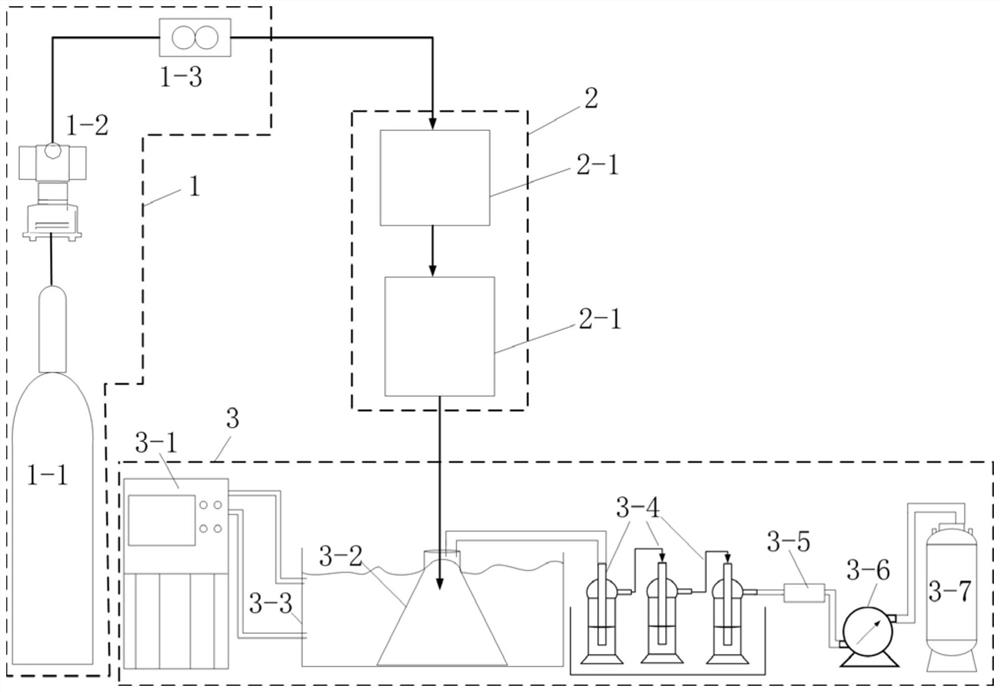

[0039] Such as figure 2 As shown, the infrared heating waste plastics pyrolysis and catalytic pyrolysis method of the present invention is the process equipment for catalytic pyrolysis of waste plastics. The components include a gas distribution system 1, a pyrolysis reactor 2, and a catalytic pyrolysis reactor 3. As well as the product recovery system 4, the specific structure and connection relationship of the components are:

[0040] The gas distribution system 1, the product recovery system 4 components and the connection relationship are the same as those described in embodiment 1, the difference is that the gas distribution system 1 is first connected to the pyrolysis reactor 2, and the pyrolysis reactor 2 is then connected to the catalytic pyrolysis reaction Device 3, catalytic pyrolysis reactor 3 is connected with product recovery system 4 again.

Embodiment 3

[0042]A pyrolysis and catalytic pyrolysis method for rapid infrared heating of waste plastics. When waste plastics are individually pyrolyzed, the pyrolysis device is connected according to the connection method described in Example 1, and the plastic (polyethylene) with a particle size of 10mm is Take by weighing 3g and pack in the pyrolysis reactor 2, connect the pipeline, the gas in the high-pressure steel cylinder 1-1 is preferably nitrogen, adjust the gas flow 100ml / min of the high-pressure steel cylinder 1-3,

[0043] The temperature of pyrolysis reactor 2 is preferably 400 DEG C, and the temperature rise rate is preferably 20 DEG C / s, and the residence time that is set at 400 DEG C is 30min, and the pyrolysis product distribution solid product that this condition obtains accounts for 0.9%, and liquid product ( Waxy) 92.6%, gas products accounted for 6.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com