Application of silane composite emulsion as anti-cracking reinforcing agent

A technology of composite emulsion and reinforcing agent, which is applied in the field of cement-based materials, can solve the problems of cement matrix strength decline and influence of cement hydration rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

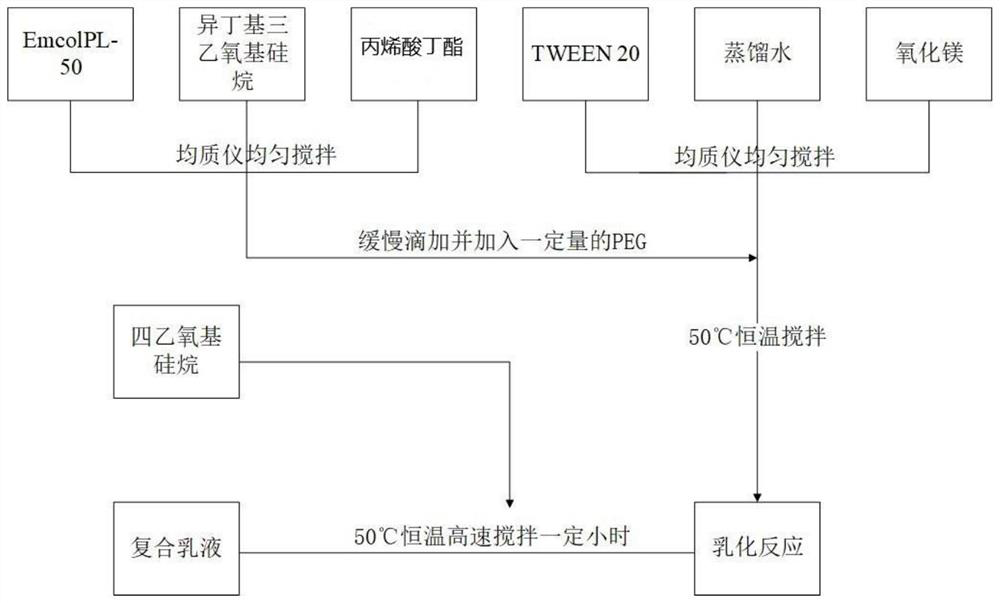

[0049] In the present invention, the preparation method of the silane composite emulsion preferably comprises the following steps:

[0050] (1) first mixing the first emulsifier, isobutyltriethoxysilane, butyl acrylate and dispersant to obtain an oil phase;

[0051] (2) The second emulsifier, magnesium oxide and water are mixed for the second time to obtain an aqueous phase;

[0052] (3) adding the oil phase and tetraethoxysilane to the water phase for emulsification reaction to obtain a silane composite emulsion;

[0053] There is no time sequence limitation between the steps (1) and (2).

[0054] In the present invention, the first emulsifier, isobutyl triethoxysilane, butyl acrylate and dispersant are first mixed to obtain an oil phase. In the present invention, a homogenizer is preferably used for the first mixing, the speed of the first mixing is preferably 1000-2200r / min, more preferably 1500-2000r / min; the temperature of the first mixing is preferably 30-65°C , more pr...

Embodiment 1

[0067] Preparation of silane composite emulsion, raw materials include:

[0068]

[0069]

[0070] The preparation method comprises the following steps:

[0071] (1) Use a homogenizer to perform the first stirring and mixing of EmcolPL-50, isobutyltriethoxysilane, butyl acrylate and dispersant at a mixing speed of 2000r / min and a temperature of 40°C to obtain an oil phase;

[0072] (2) Use a homogenizer to carry out the second stirring and mixing of TWEEN 20, magnesium oxide and water, the mixing speed is 2000r / min, and the temperature is 40°C to obtain the water phase;

[0073] (3) The oil phase is added dropwise to the water phase, and stirred at a constant temperature at 40°C. After the dropwise addition is completed, the emulsification reaction is carried out under stirring at 2500r / min. The temperature of the emulsification reaction is 50°C, and the time is 4h, to obtain Silane complex emulsion;

[0074] The flow chart of the preparation method is as figure 1 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com