A phosphorylated peptide adsorbent and its preparation and application

A phosphorylated peptide and adsorbent technology, applied in the field of immobilized metal ion affinity chromatography materials, can solve the problems of unfavorable large-scale preparation, harsh reaction conditions, and complicated preparation process, and achieve good application prospects, low cost, and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

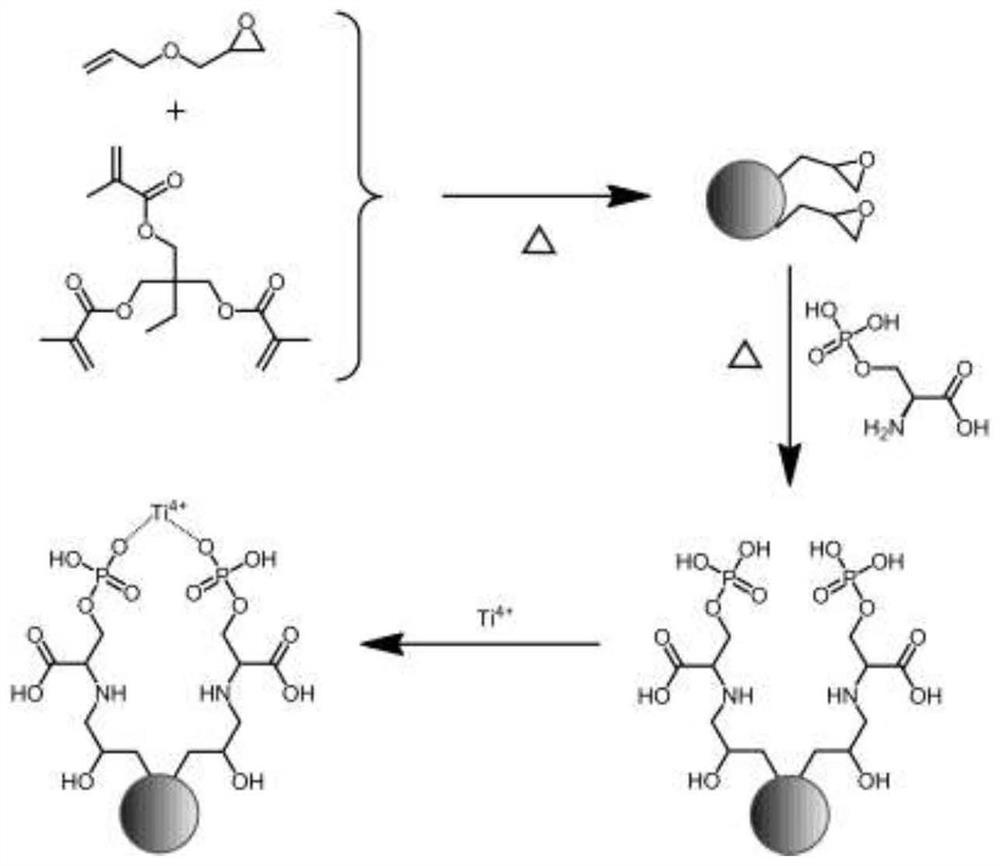

[0015] Example 1 Ti prepared based on epoxy polymer microspheres 4+ -IMAC functional materials used in the separation and enrichment of Ti phosphopeptides 4+ - Preparation of IMAC functional materials:

[0016] (1) Preparation of polymer microspheres functionalized with epoxy groups: 0.5 g of polyvinyl alcohol was added to 60 mL of methanol-water mixed solvent (methanol / water=5 / 2, volume ratio), heated to 60° C. It was completely dissolved, then cooled to room temperature (22°C), then 2g of allyl glycidyl ether and 2g of trimethylolpropane trimethacrylate were added dropwise, and then 60mg of azobisisobutyronitrile was added, at 70°C In an oil bath, mechanically stir at a stirring rate of 500rpm, heat up to 85°C after 2h, stop heating after continuing the reaction for 30min, wash the product with methanol and water in turn, remove residual reagents, and vacuum dry at 60°C for 12h to obtain epoxy polymer object microspheres.

[0017] (2) Preparation of polymeric microspheres...

Embodiment 2

[0025] Example 2 Commercial Ti 4+ -IMAC microspheres for separation and enrichment of phosphorylated peptides

[0026] Commercial Ti 4+ - IMAC microspheres were purchased from Bailingwei Reagent Co., Ltd., and the process of enrichment of phosphopeptides and identification by mass spectrometry were the same as in Example 1.

[0027] Material Characterization:

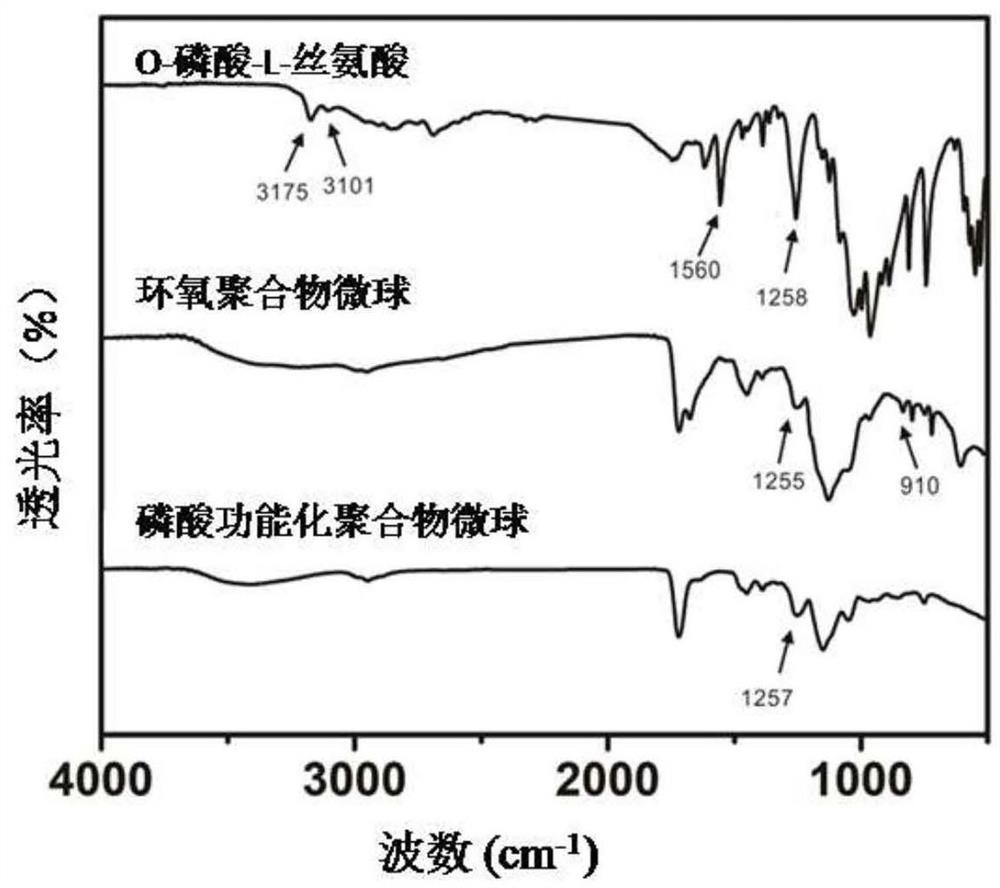

[0028] The epoxy polymer microspheres, phosphoserine-polymer microspheres and O-phospho-L-serine monomer were characterized by Fourier transform attenuated total reflection infrared spectroscopy (ATR-FTIR). Such as figure 2 As shown, the wave number at 910cm appeared in the spectrum of epoxy polymer microspheres -1 and 1255cm -1 The characteristic vibration peak of the epoxy group, while the wave number in the spectrum of phosphoserine-polymer microspheres is at 910cm -1 The absorption peak disappears, and the wavenumber is at 1255cm -1 The intensity of the absorption peak also decreased significantly, indicatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com