Dynamic catalytic water treatment ceramic membrane and application thereof

A ceramic membrane and water treatment technology, applied in the fields of water treatment, ozone catalysis and ceramic membrane filtration, can solve the problems of poor membrane filtration accuracy, many membrane defects, and low membrane separation efficiency, and achieve low permeability resistance and mass transfer efficiency. High and catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

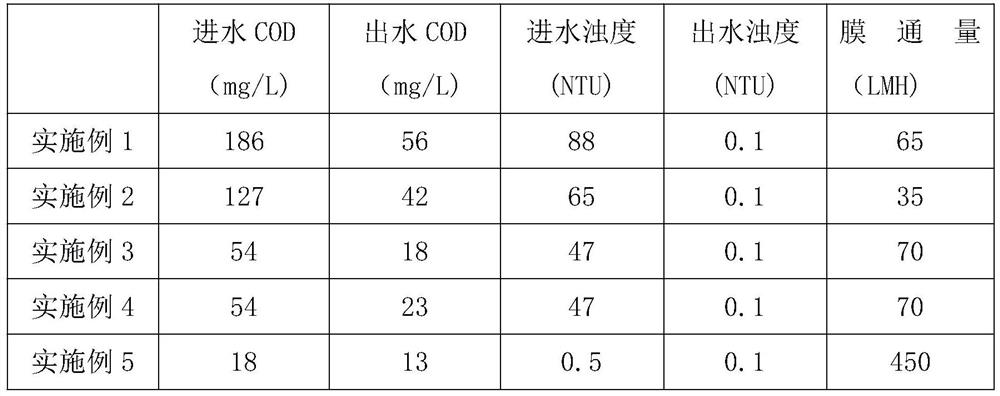

Examples

Embodiment 1

[0028] Step (1) is to modify the commercial titanium dioxide particles with a particle size range of 0.1 to 0.5 μm into microspheres with rounded particles and uniform size through ball milling technology; prepare metal manganese alkoxide sol; Titanium dioxide microspheres were immersed in metal manganese alkoxide sol for 4 hours, and the titanium dioxide microspheres after centrifugation were dried in an oven at 100°C for 3 hours; finally, the dried titanium dioxide microspheres were kept in a muffle furnace at 600°C for 3 hours, Nanoparticles coated with a layer of manganese metal.

[0029]Step (2) is to disperse the titanium dioxide microspheres coated with metal manganese nanoparticles prepared in step (1) in the feed tank of 500L according to 1wt%; Before entering the biochemical tail water of the industrial wastewater treatment plant, the suspension of titanium dioxide microspheres coated with dispersed metal manganese nanoparticles was circulated in a cross-flow at a pr...

Embodiment 2

[0034] Step (1) is to modify the commercial titanium dioxide particles with a particle size range of 0.1 to 0.5 μm into microspheres with rounded particles and uniform size through ball milling technology; prepare metal manganese alkoxide sol; Titanium dioxide microspheres were immersed in metal manganese alkoxide sol for 4 hours, and the titanium dioxide microspheres after centrifugation were dried in an oven at 100°C for 3 hours; finally, the dried titanium dioxide microspheres were kept in a muffle furnace at 600°C for 3 hours, Nanoparticles coated with a layer of manganese metal.

[0035] Step (2) is to disperse the titanium dioxide microspheres coated with metal manganese nanoparticles prepared in step (1) in the membrane pool of 1000L according to 1wt%; adopt the silicon carbide flat ceramic membrane negative pressure suction type with 0.1 μm aperture Dead-end filtration, before entering the biochemical tail water of the domestic sewage treatment plant, the suspension of...

Embodiment 3

[0040] Just change metal manganese into metal cobalt in embodiment 2, the treated domestic sewage is changed into a certain river channel water in Zhejiang, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com