Composite microbial preparation for degrading high-oil-content kitchen waste and preparation method and application thereof

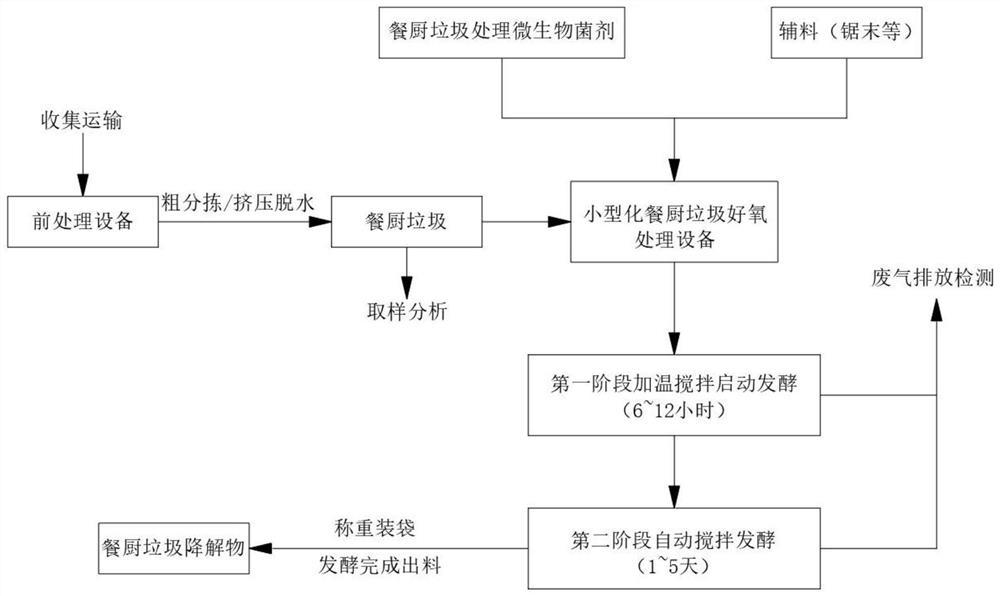

A technology for compounding microorganisms and kitchen waste, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc. Air contact specific surface area and other issues to achieve the effect of reducing odor concentration, rapid decomposition, and reducing the release of NH3 and H2S

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned compound microbial preparation for degrading high-oil-containing kitchen waste specifically includes the following steps:

[0030] S1, activated strains

[0031] Inoculate each original strain of the composite microbial preparation on the solid medium corresponding to each strain for activation culture, in which Acinetobacter johnsonii, Bacillus subtilis and Geobacillus stearothermophilus are inoculated on the LB medium, 30~ Cultivate at 40°C for 24-36 hours; inoculate Candida utilis and Phanerochaete chrysosporium on PDA medium, and culture at 25-30°C for 36-48 hours; activate each strain to obtain each single activated strain;

[0032] S2, primary seed liquid shake flask culture

[0033] Each strain activated in S1 was inoculated into the corresponding Erlenmeyer flask liquid medium for shaking flask culture, in which Acinetobacter johnsonii, Bacillus subtilis and Geobacillus stearothermophilus were inoculated on the LB l...

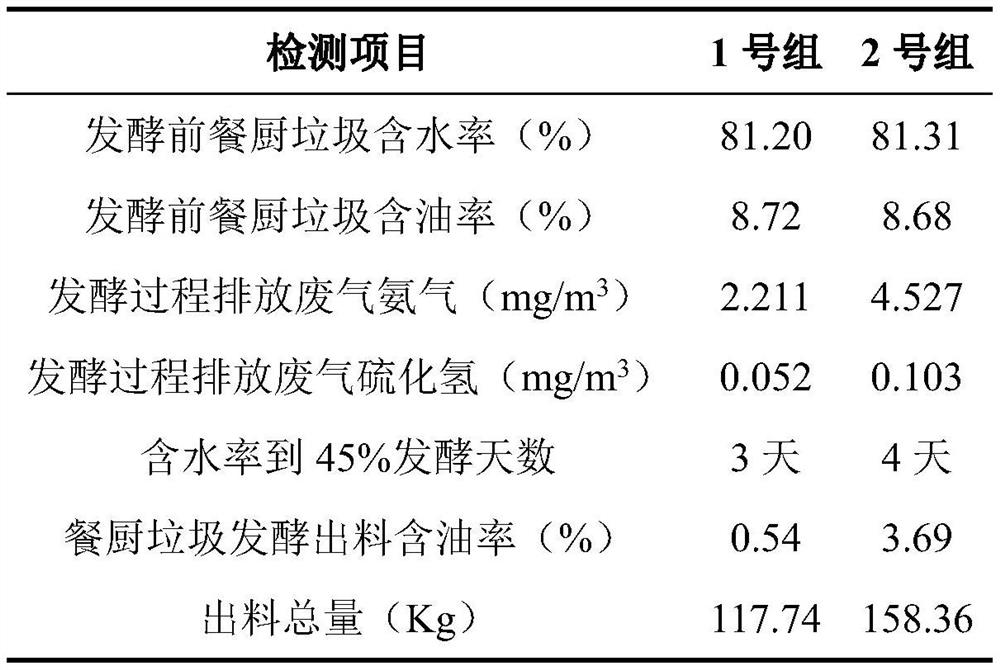

Embodiment 1

[0051] The compound microbial preparation for degrading food waste with high oil content includes Acinetobacter johnsonii, which accounts for 30% of the total bacterial count in the preparation, Candida utilis, which accounts for 20% of the total bacterial count in the preparation, and Chrysosporium chrysosporium, which accounts for 10% of the total bacterial count in the preparation. Phaneroderma, Bacillus subtilis accounting for 20% of the total number of bacteria in the preparation and Geobacillus stearothermophilus accounting for 20% of the total number of bacteria in the preparation.

Embodiment 2

[0053] The compound microbial preparation for degrading high-oil-containing food waste includes Acinetobacter johnsonii accounting for 40% of the total bacterial count in the preparation, Candida utilis accounting for 15% of the total bacterial count in the preparation, and Chrysosporium chrysosporium accounting for 15% of the total bacterial count in the preparation Phaneroderma, Bacillus subtilis accounting for 15% of the total number of bacteria in the preparation and Geobacillus stearothermophilus accounting for 15% of the total number of bacteria in the preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com