A kind of Juncao fiberboard and preparation method thereof

A technology of fiberboard and Juncao, which is applied in the field of fiberboard, can solve the problems of unsuitable particleboard raw materials and large particleboard volume, and achieve the effects of reducing long cultivation period, fast growth speed and alleviating contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

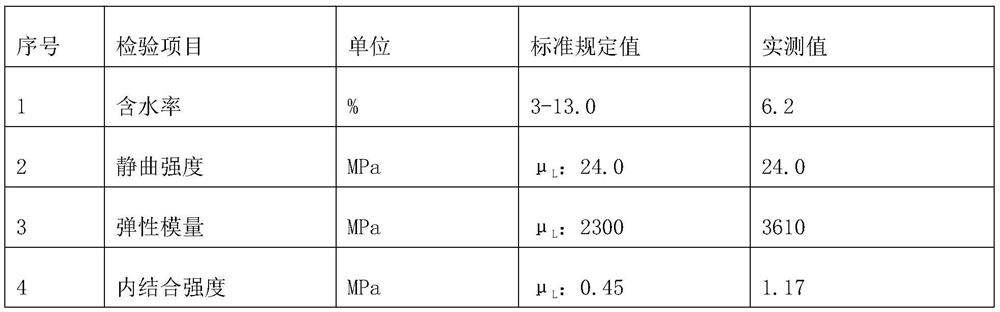

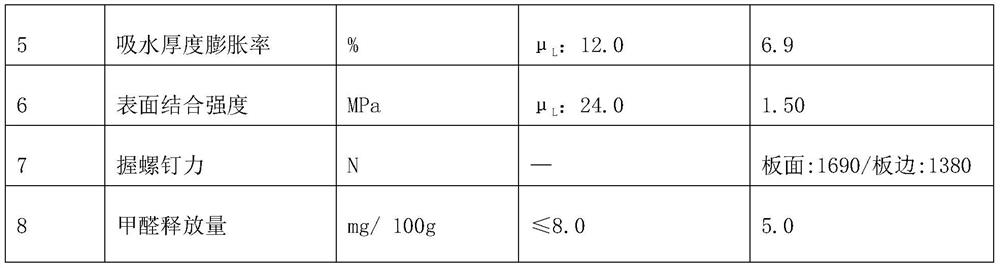

[0025] Embodiment 1 A kind of thickness is 18mm Juncao fiberboard and preparation method thereof

[0026] Cutting: Cut the 1.5-year-old Oasis No. 1 Juncao with a water content of 50.2% to a length of 2-3cm;

[0027] Cooking: After cutting, the Juncao is boiled and softened under high pressure; the cooking temperature is controlled to be 158-160°C, the steam pressure is 5.0-5.5bar, and the cooking time is 2-3min;

[0028] Defibrillation and sizing: the cooked Juncao is mechanically decomposed into fibers in a thermal mill; in the process of ejecting fibers from the thermal mill, an adhesive is added to obtain sizing Juncao fibers; the addition of adhesive The amount is 10% urea-formaldehyde resin of the quality of the cooked Juncao;

[0029] Drying: Use a flash dryer to air dry the sizing Juncao fiber at 120-160°C, and the moisture content of the dried Juncao fiber is 8.05%;

[0030] Paving, sweeping and pre-pressing: the dried Juncao fibers are paved, smoothed and pre-presse...

Embodiment 2

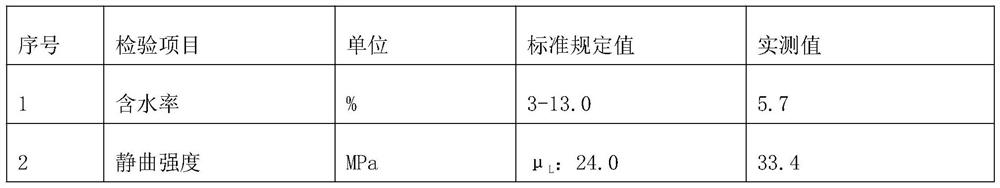

[0037] Embodiment 2 A kind of thickness is 12mm Juncao fiberboard and preparation method thereof

[0038] The difference from Embodiment 1 is that in this embodiment:

[0039] Cutting: Cut the 2-year-old Oasis No. 1 Juncao with a water content of 59.5% into a length of 2-3cm;

[0040] Cooking: soften the cut Juncao by high-pressure cooking; the cooking temperature is 158-160°C, the steam pressure is 5.0-5.5bar, and the cooking time is 2-3min;

[0041] Defibrillation and sizing: the cooked Juncao is mechanically decomposed into fibers in a thermal mill; during the process of ejecting fibers from the thermal mill, an adhesive is added to obtain sizing Juncao fibers; The addition amount is 14.9% urea-formaldehyde resin of the quality of Juncao after cooking;

[0042] Drying: Use a flash dryer to air dry the sizing Juncao fiber at 120-160°C, and the moisture content of the dried Juncao fiber is 8.5%;

[0043] Paving, sweeping and pre-pressing: Pave, sweep and pre-press the drie...

Embodiment 3

[0049] Embodiment 3 A kind of thickness is 15mm Juncao fiberboard and preparation method thereof

[0050] The difference with the above two embodiments is that cutting: cutting the 1-year-old Oasis No. 1 Juncao with a water content of 54.5% into a length of 2-3cm;

[0051] Cooking: soften the cut Juncao by high-pressure cooking; the cooking temperature is 158-160°C, the steam pressure is 5.0-5.5bar, and the cooking time is 2-3min;

[0052] Defibrillation and sizing: the cooked Juncao is mechanically decomposed into fibers in a thermal mill; during the process of ejecting fibers from the thermal mill, an adhesive is added to obtain sizing Juncao fibers; The addition amount is 13.0% urea-formaldehyde resin of the quality of Juncao after cooking;

[0053] Drying: use a flash dryer to air dry the sizing Juncao fiber at 120-160°C, and the moisture content of the dried Juncao fiber is 8.35%;

[0054] Paving, sweeping and pre-pressing: the dried Juncao fiber is paved, sweeping and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com