Crushing equipment for fused silica powder production and processing

A crushing equipment and silicon micropowder technology, applied in the field of fused silica micropowder, can solve problems such as high energy consumption costs, failure to meet user needs, and low processing efficiency, and achieve the effects of cost reduction, high practical value, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

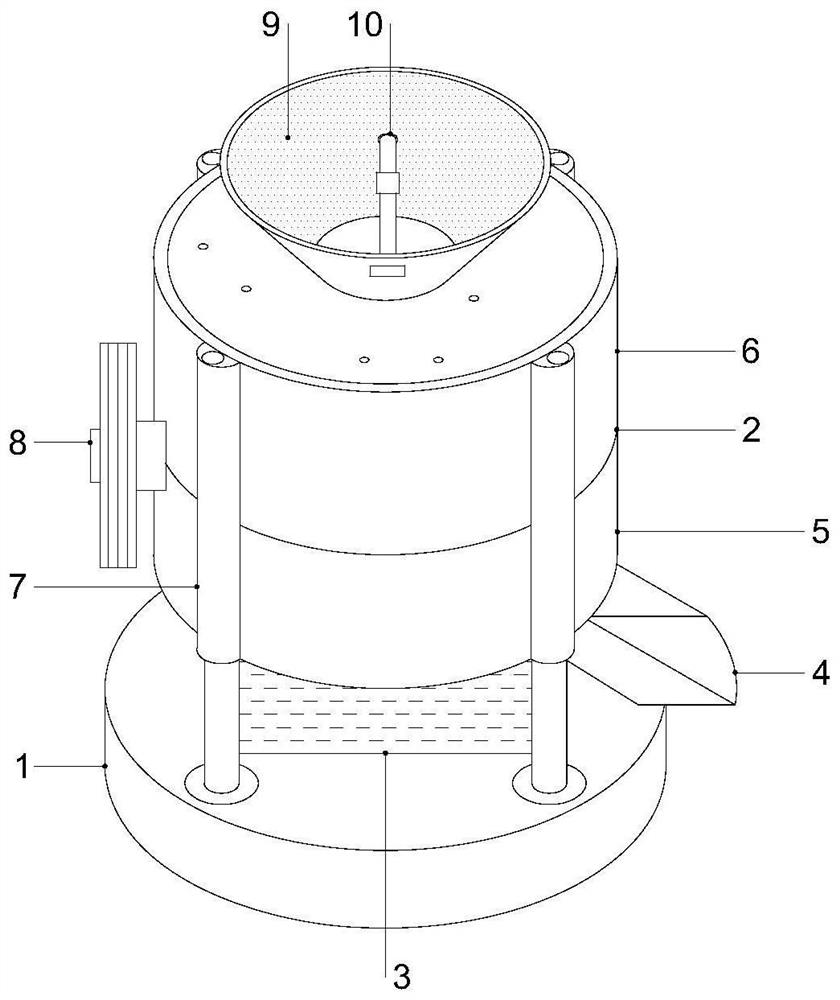

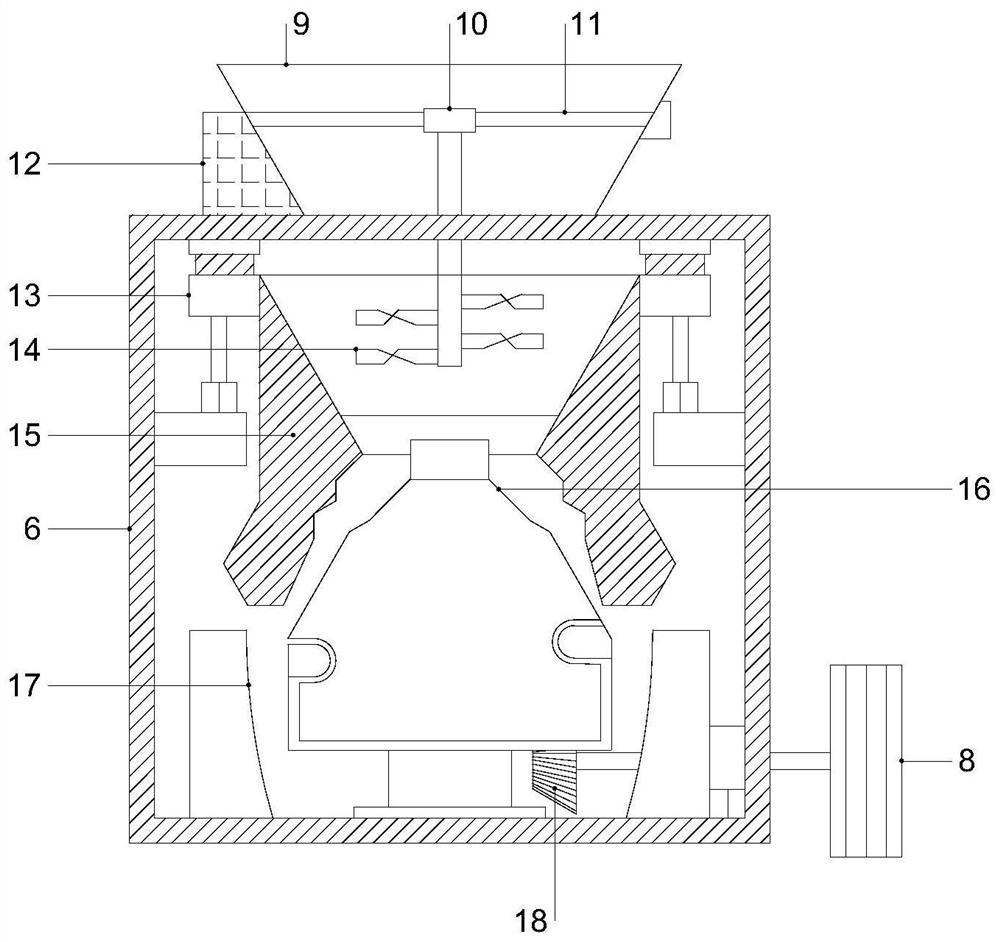

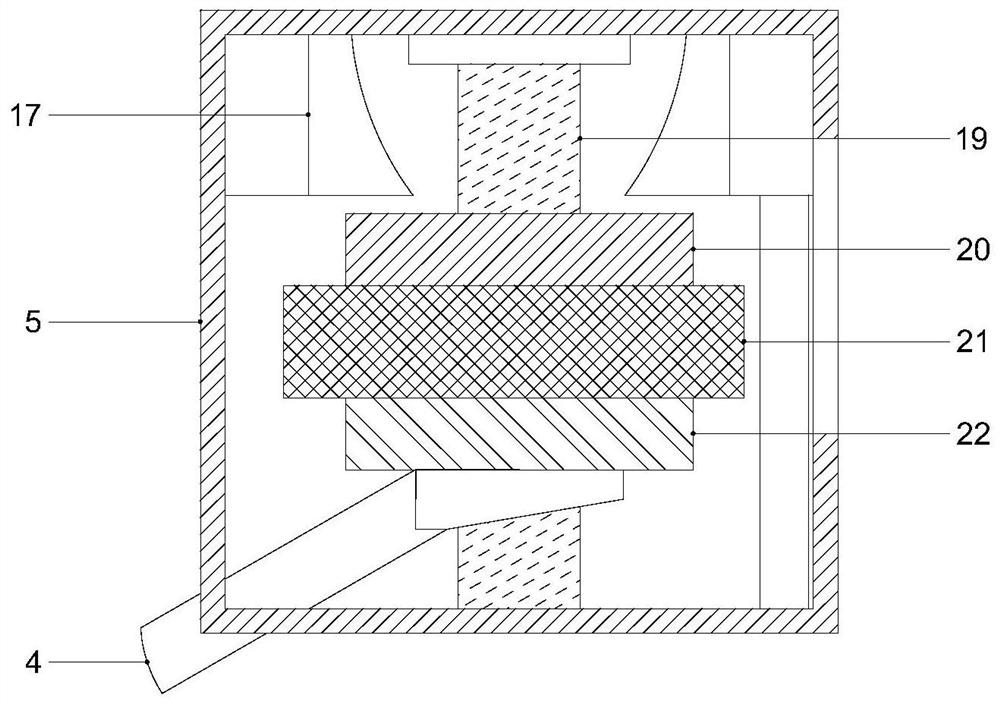

[0021] Example: such as Figure 1-3 As shown, a crushing equipment for production and processing of fused silica powder according to the present invention includes a base 1, a drive motor 3 is fixedly installed in the center of the top of the base 1, and a shock-absorbing support 7 is fixedly installed in the four corners of the top of the base 1;

[0022] The main body 2 is composed of a coarse crushing box 5 and a fine crushing box 6. The top of the coarse crushing box 5 is equipped with a feeding funnel 9 and a stirring device 10. The stirring device 10 includes a transmission rod 11, a rotating motor 12 and a stirring paddle 14. , the top of the rough crushing box 5 is fixedly installed with a fixed crushing fast 15, and the side wall of the fixed crushing fast 15 is equipped with an inner shock absorber 13, and the bottom of the fixed crushing fast 15 is equipped with a rocking crushing head 16, and the rocking crushing head 16 is installed. The bottom of the crushing hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com