Chemical fiber single-bundle water repellent and oil repellent treatment device unit

A chemical fiber, single bundle technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below, and the embodiments are only used to explain the present invention, but not to be construed as limiting the present invention.

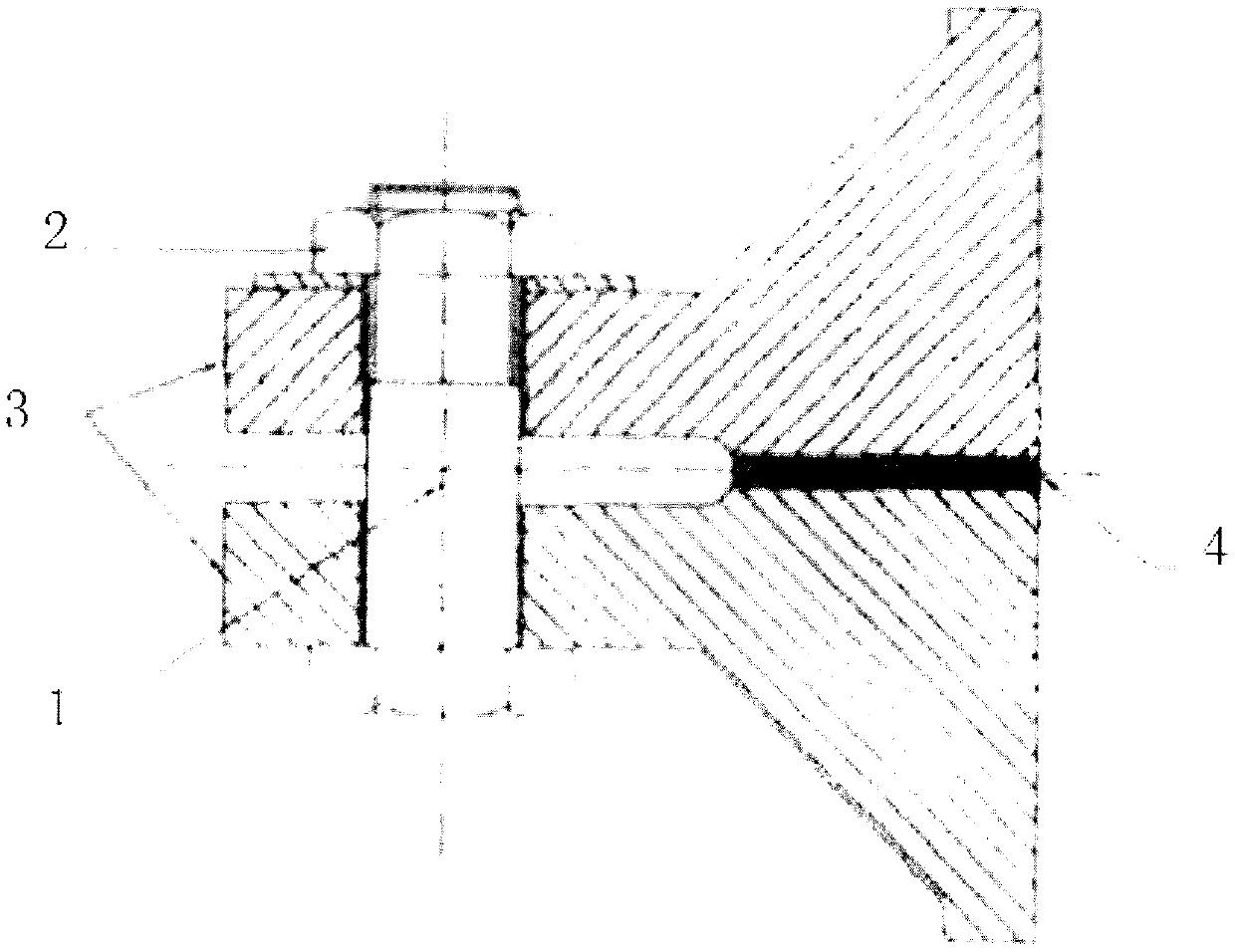

[0025] The chemical fiber used in the woven filter cloth used in this embodiment, the fiber type: polyamide fiber; the fineness is 120D; the form of monofilament and single bundle; the packaging form: packaged.

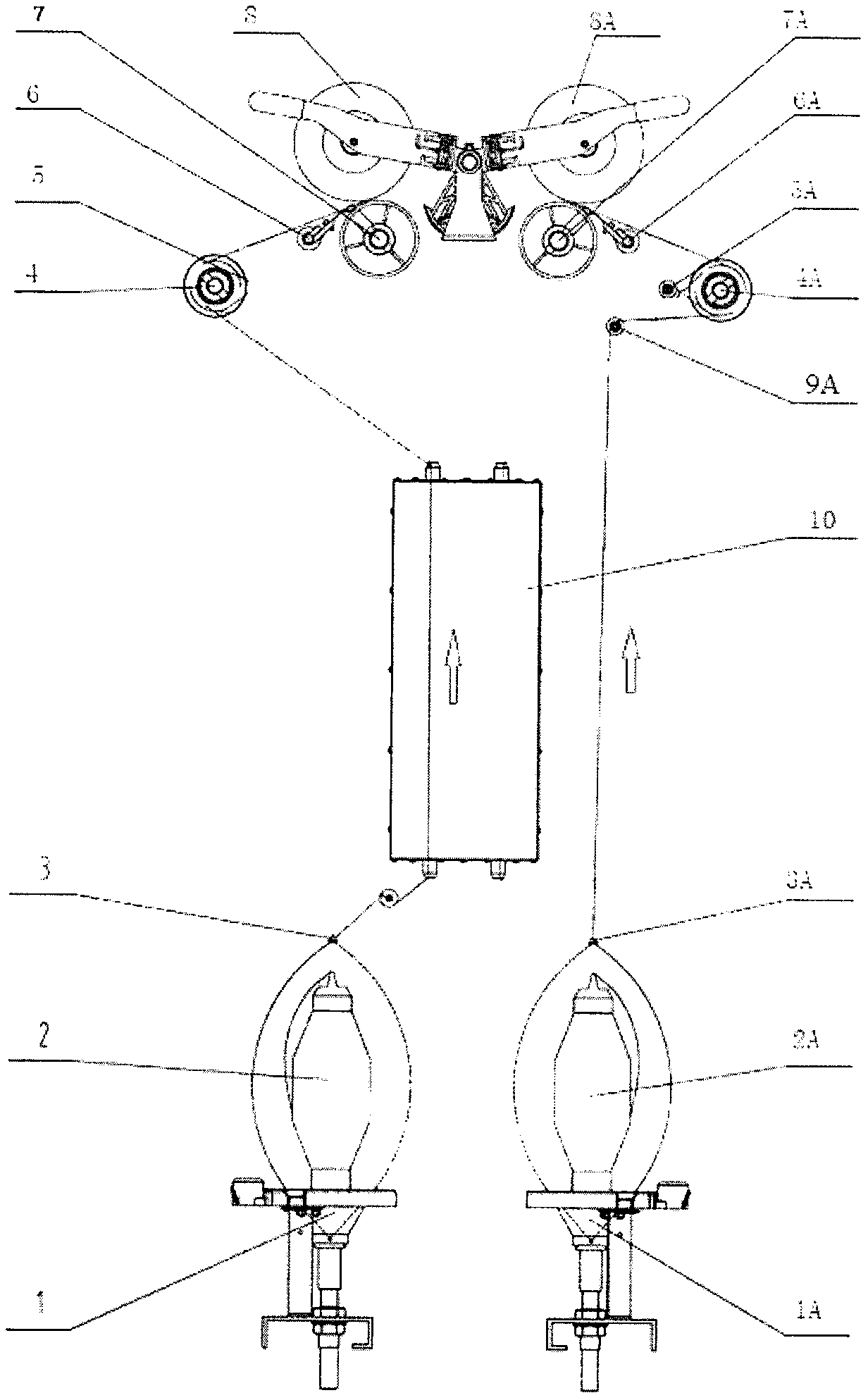

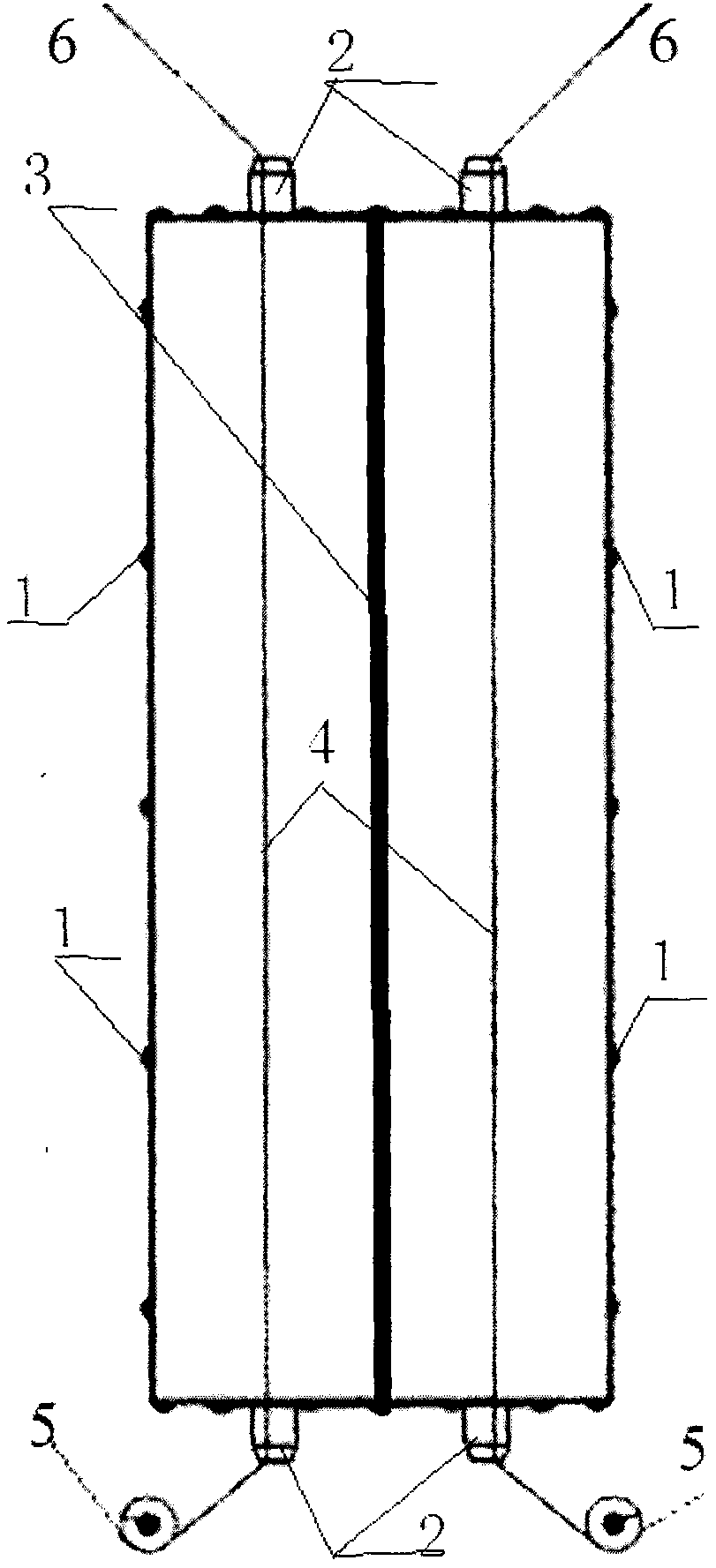

[0026] The specific process flow of this embodiment is as follows: the commercially available 120D polyamide monofilament fiber in drums is subjected to oil and dirt repelling treatment through a winder equipped with the device unit described in the present invention.

[0027] Installed machine: the device unit of the present invention is installed on the domestic tube-to-tube type simple rewinding machine; model: double-sided type; number of spindles: 24 spindles, that is: 12 spindles per side; 12 spindles described in the present invention The device units are r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com