Inner container, container and manufacturing method

A manufacturing method and liner technology, which is applied in the field of containers and liner manufacturing, can solve the problems of infiltration, increased production costs, and poor thermal insulation performance of titanium cups, and achieve the effects of increasing wall strength, strengthening connection strength, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

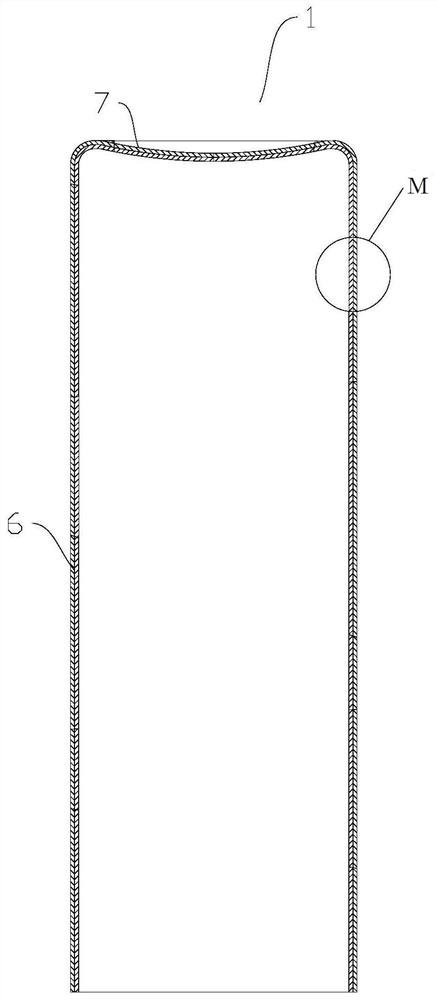

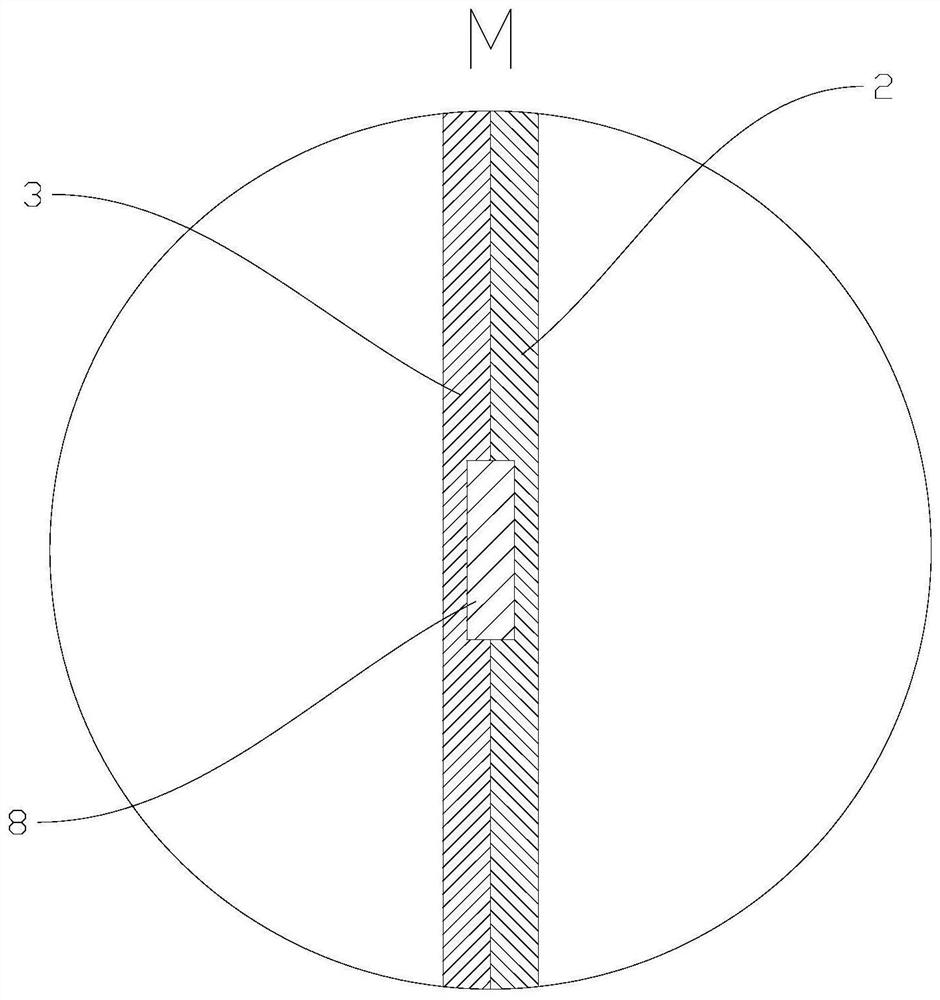

[0035] a liner, such as Figure 1 to Figure 3 As shown, it includes an inner container body 1, which is composed of an outer layer inner container 2 and an inner layer inner container 3, and also includes a seam welding ring 8 arranged between the outer layer inner container 2 and the inner layer inner container 3. Roll welding rings 8 are evenly distributed from the bottom of the inner container to the mouth of the inner container. The connection strength between the outer liner 2 and the inner liner 3 is enhanced, and water or impurities are prevented from entering the outer liner 2 and the inner liner 3, which affects the use of the inner liner 1.

[0036] The inner liner 3 is made of titanium material, and the outer liner 2 is made of metal material other than titanium material. The outer liner 2 is made of stainless steel, copper or aluminum. The thickness of liner 1 is 0.05-0.5 mm, and the thickness of inner liner 3 is 0.03-0.2 mm. When the inner tank body 1 is filled...

Embodiment 2

[0040] A kind of manufacturing method of liner, such as figure 1 , figure 2 , Figure 4 , Figure 5 Shown, be used to manufacture a kind of liner described in embodiment 1, comprise the following steps:

[0041] Step 1, taking the inner liner blank formed by compounding the outer liner 2 and the inner liner 3;

[0042] Step 2, process the liner blank by the seam welding process, so that a seam welding ring 8 is formed between the outer liner 2 and the inner liner 3

[0043] Step 3, performing hot or cold spinning processing on the side wall of the liner blank to form the liner body 1 including the outer liner 2 and the outer liner 2 . The liner body 1 is the liner of the thermos cup or the liner of the pot.

[0044] The seam welding process in step 2 includes:

[0045] 1), inserting the copper mandrel 4 connected to the negative pole of the power supply inside the inner liner 3 and driving the inner liner blank to rotate;

[0046] 2), the seam welding wheel 5 connected...

Embodiment 3

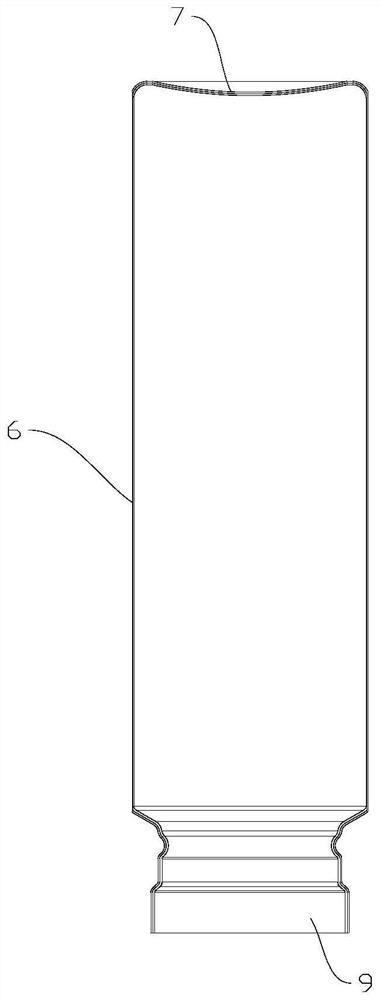

[0054] A kind of manufacturing method of liner, such as Figure 1 to Figure 3 as well as Figure 5 As shown, the difference from Example 1 is that when the inner container body 1 is a thermos cup inner container, step 4 is also included, and the mouth of the inner container body 1 is screwed and compressed to form a cup mouth 9 . The liner body 1 is formed into a thermos cup liner. When the thermos cup is filled with a solution, the inner liner 3 made of titanium material is in contact with the solution to improve the hygiene and health of the thermos cup when it is filled with a solution.

[0055] The invention also discloses a manufacturing method of a container. After the inner container is manufactured as above, step 5 is also included. The connection is fixed and sealed, and a vacuum is drawn between the inner tank body 1 and the outer shell 12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com