Hollow waveguide cavity for enhancing gas Raman signal

A Raman signal and waveguide cavity technology, which is applied in Raman scattering, material excitation analysis, instruments, etc., can solve the problems of poor optical stability, low detection limit, and short detection time of resonant cavity technology, and achieve fast Raman spectroscopy The effects of detection, improved speed of entry and exit, and improvement of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

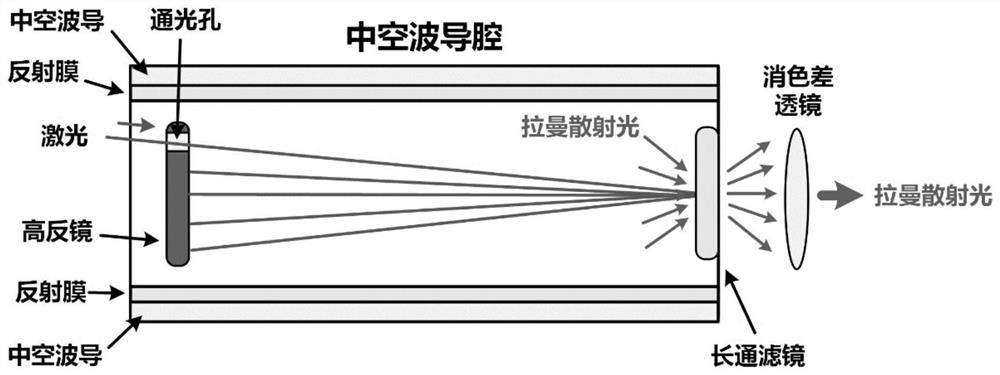

[0060] The hollow waveguide is a hollow tube made of silica, with a length of 0.5 m, an outer diameter of 35 mm, and an inner diameter of 28 mm.

[0061] The high reflection mirror is a circular plano-concave mirror with a diameter of 25 mm, a concave reflective surface, and a radius of curvature of 0.5 m.

[0062] The high reflection mirror has a light hole through which the laser enters the hollow waveguide cavity. The diameter of the light hole is 3mm, and the distance from the center of the light hole to the center of the high reflection mirror is 20mm.

[0063] The long-pass filter is a circular plane mirror with a diameter of 25mm, which sets the cut-off wavelength of the light wave according to the laser wavelength. For example, if the laser wavelength is 532nm, the cut-off wavelength is 533nm.

[0064] The achromatic lens is a circular biconvex lens with a diameter of 25mm and a focal length of 0.5m for light of 500nm-700nm.

[0065] Such as figure 2 As shown, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com