Recyclable enhanced performance carbon fiber reinforced polymers

A fiber-reinforced, recycled fiber technology used in FRP. field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

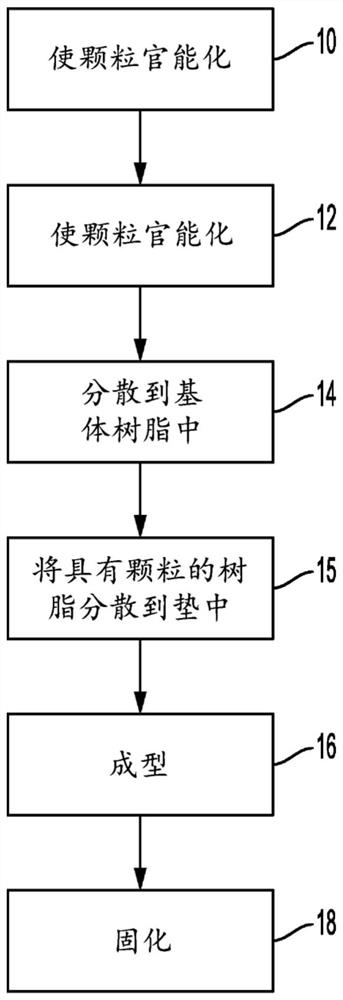

Method used

Image

Examples

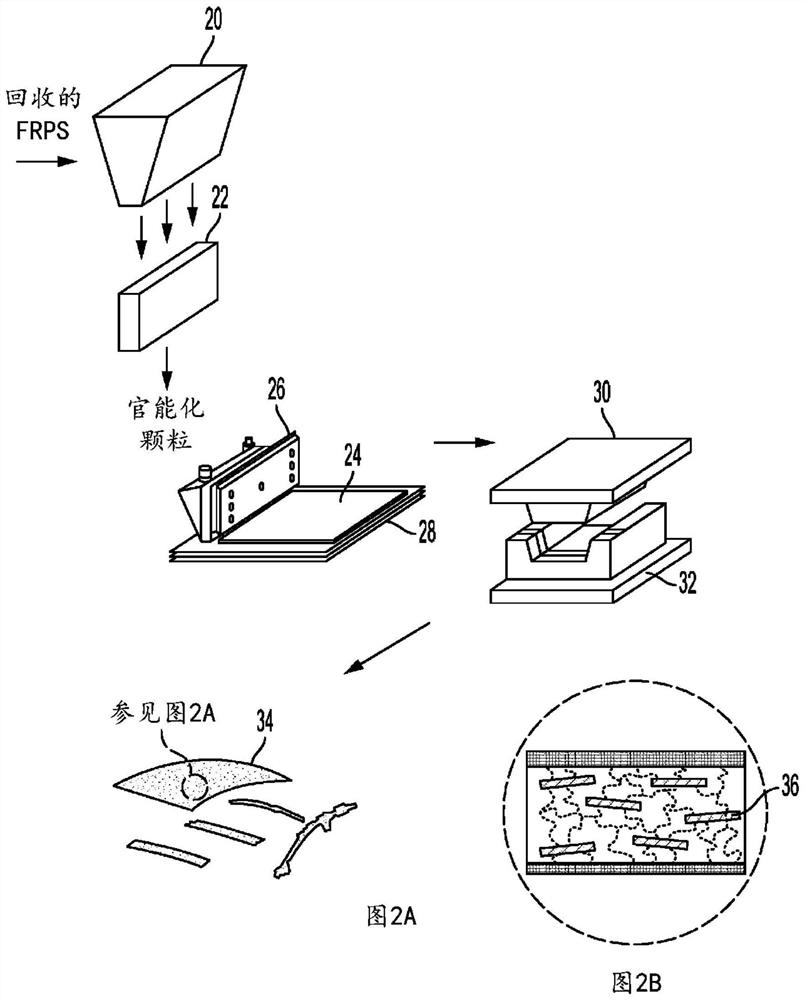

Embodiment Construction

[0017] Embodiments herein enable the manufacture of lightweight, paintable CFRP parts with a Class A surface finish, a weight reduction of over 70% when compared to a steel roof, and an acceptable cost increase (less than the saved $5.00 per pound), offset by fuel savings achieved through lightweighting while being able to recycle CFRP at end-of-life. CFRP parts can also be made from other recycled fiber reinforced polymers (FRP) including fiber reinforced plastics.

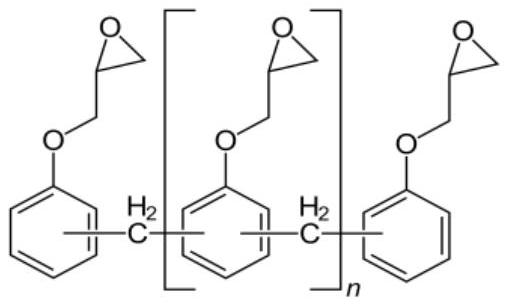

[0018] Embodiments herein include composite resin formulations that, after curing, incorporate a high glass transition temperature epoxy resin, meaning that it has a glass transition temperature greater than 150°C. The formulation includes recycled functionalized CFRP particles having functional groups that are similar to or compatible with epoxy resins and that react with epoxy resins when cured. This creates a cross-linked structure with a network of chemically linked CFRP particles distributed within the cure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com