In-situ micro-glass-fiber reinforced polymer based 3D printing consumables as well as preparation method and equipment thereof

A 3D printing and polymer technology, applied in the field of material science, to achieve the effect of easy continuous production, easy large-scale production, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1 of the present invention: in-situ micro glass fiber reinforced polymer 3D printing consumables, calculated by mass parts, including 80 parts of PLA, 18 parts of phosphate glass-ceramic and 5502 parts of silane coupling agent Kh. Phosphate glass-ceramic is prepared by firing stannous chloride and ammonium dihydrogen phosphate at a mass percentage of 1:1 at 500°C for 25 minutes, and its glass transition temperature is 215°C.

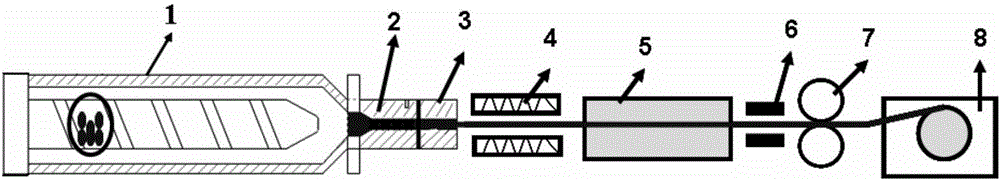

[0014] The preparation method of in-situ micro-glass fiber reinforced polymer 3D printing consumables, each component is taken according to the above-mentioned mass parts, and the polymer matrix, phosphate glass-ceramic and coupling agent are premixed evenly, and then reinforced with in-situ glass fiber Polymer 3D printing consumables production equipment is extruded, and after extrusion, after stretching, cooling, and winding processes, in-situ micro-glass fiber reinforced polymer 3D printing consumables are prepared.

[0015] In-situ gla...

Embodiment 2

[0017] Example 2 of the present invention: in-situ micro glass fiber reinforced polymer 3D printing consumables, calculated by mass parts, including 84 parts of EVA, 15 parts of phosphate glass-ceramic and 1 part of titanate coupling agent KR101. Phosphate glass-ceramic is prepared by firing stannous chloride and ammonium dihydrogen phosphate at a mass percentage of 1:1 at 500°C for 25 minutes, and its glass transition temperature is 215°C.

[0018] The preparation method and production equipment are the same as in Example 1.

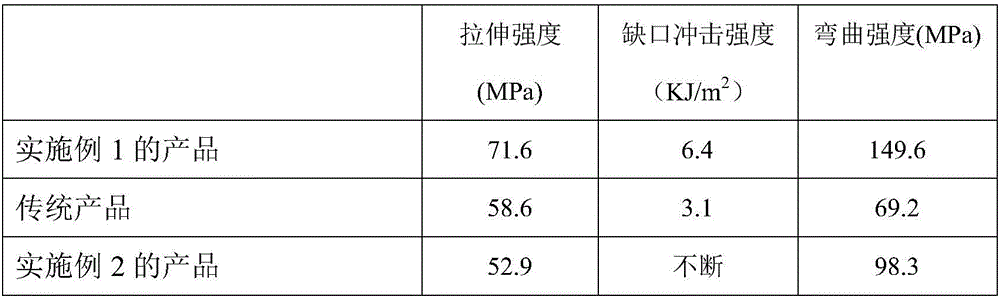

[0019] In order to verify the effect of the present invention, the mechanical properties of the in-situ micro glass fiber reinforced polymer 3D printing consumables prepared by the above implementation examples were tested for mechanical properties, and the results are shown in the following table:

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com