Non-symmetric composite reinforced concrete pouring supporting pile

A composite reinforcement and supporting pile technology, applied in sheet pile walls, excavation, construction, etc., can solve the problems of heavy weight, difficult to hoist, construction, affect the performance of supporting piles, easy to be corroded, etc., and achieve a wide range of use. , Easy to hoist the cage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

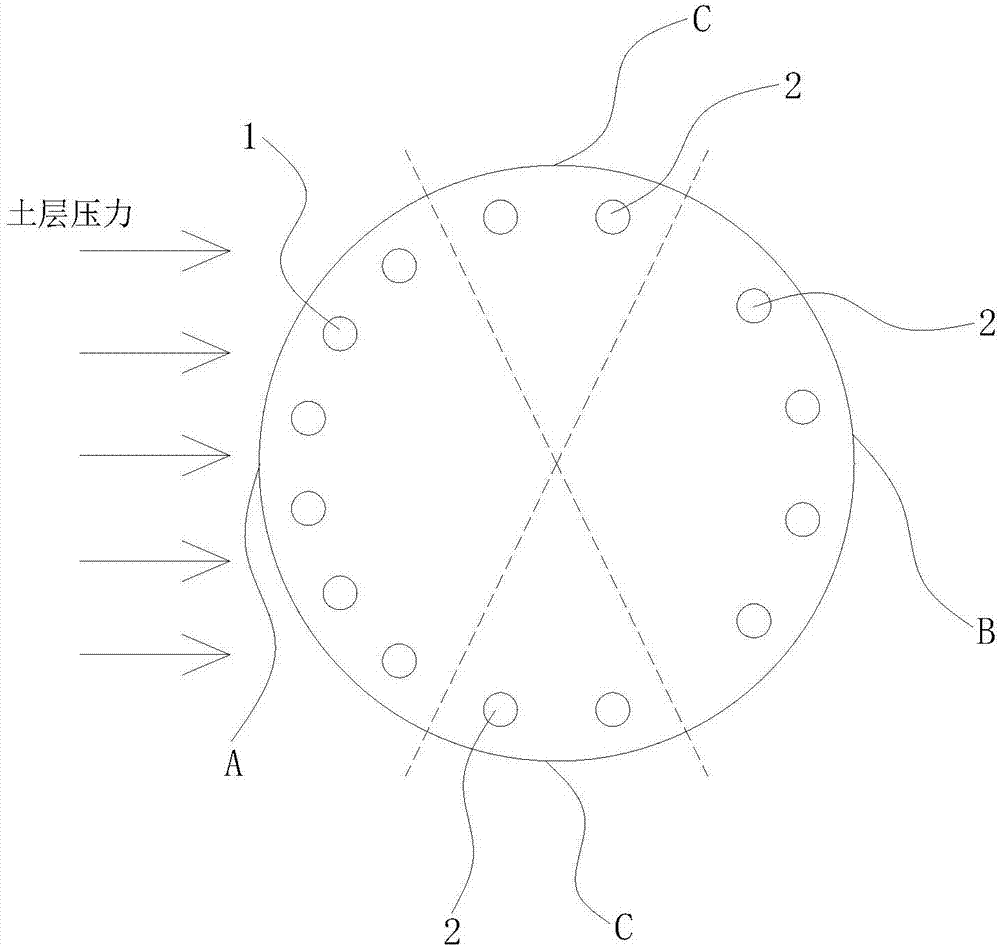

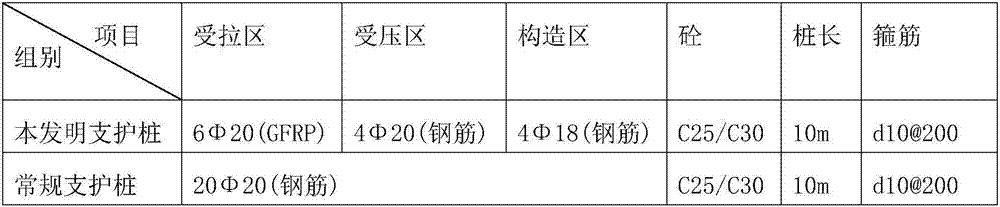

[0016] Such as figure 1 As shown, the present invention includes a tension zone A whose side is close to the soil layer and a compression zone B whose side is away from the soil layer. The reinforcement in the tension zone A is composed of glass fiber reinforcements 1 arranged at intervals along the circumference of the support pile. Or it is composed of glass fiber bars 1 and steel bars 2 arranged alternately along the circumferential direction of the support pile; the reinforcement in the pressure zone B is composed of steel bars 2 arranged at intervals along the circumferential direction of the support pile; the glass fiber bars 1 , The axial direction of steel bar 2 is parallel to the axial direction of the support pile. The support pile of the present invention adopts glass fiber bars 1 or glass fiber bars 1 and steel bars 2 in the tension area A t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com