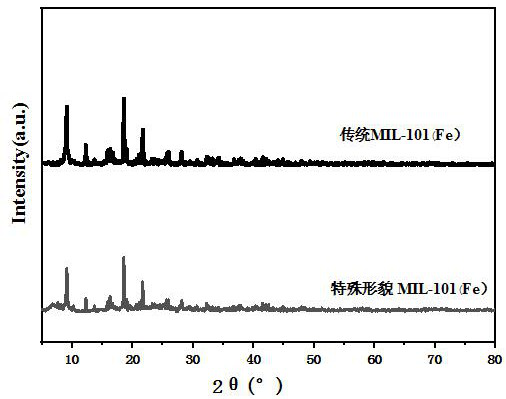

Synthesis and photocatalytic application of spindle-shaped MIL-101 (Fe) photocatalyst

A photocatalyst and spindle technology, applied in the field of nanomaterials, can solve the problem that active sites cannot participate in photocatalytic reactions, and achieve good photocatalytic activity, increase ammonia production, and simple and safe conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Weigh 0.135g of ferric chloride hexahydrate, place it in 15mL of ethylene glycol, stir at 40°C for 1 hour to form A solution; weigh 0.206g of terephthalic acid and 0.675g of ferric chloride hexahydrate Dissolve in 20mL N,N-dimethylformamide solvent to form B solution, pour A solution into B solution, stir evenly, put the solution into a 50 mL high-pressure stainless steel reaction kettle with polytetrafluoroethylene lining , reacted at 110 °C for 20 h. The resulting precipitate was centrifuged, washed with DMF and anhydrous methanol, and dried at 80 °C to obtain MIL-101(Fe)-1 with special morphology.

Embodiment 2

[0022] Example 2: Weigh 0.135g of ferric chloride hexahydrate, place in 15mL of ethylene glycol, stir at 40°C for 2h to form A solution; weigh 0.206g of terephthalic acid and 0.675g of ferric chloride hexahydrate Dissolve in 20mL N,N-dimethylformamide solvent to form B solution, pour A solution into B solution, stir evenly, put the solution into a 50 mL high-pressure stainless steel reaction kettle with polytetrafluoroethylene lining , reacted at 110 °C for 20 h. The resulting precipitate was centrifuged, washed with DMF and anhydrous methanol, and dried at 80 °C to obtain MIL-101(Fe)-2 with a special shape.

Embodiment 3

[0023] Example 3: Weigh 0.135g of ferric chloride hexahydrate, place in 15mL of ethylene glycol, stir at 40°C for 3h to form A solution; weigh 0.206g of terephthalic acid and 0.675g of ferric chloride hexahydrate Dissolve in 20mL N,N-dimethylformamide solvent to form B solution, pour A solution into B solution, stir evenly, put the solution into a 50 mL high-pressure stainless steel reaction kettle with polytetrafluoroethylene lining , reacted at 110 °C for 20 h. The resulting precipitate was centrifuged, washed with DMF and anhydrous methanol, and dried at 80 °C to obtain MIL-101(Fe)-3 with a special shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com