Porous ceramic atomizing core and preparation method thereof

A technology of porous ceramics and atomizing cores, applied in the field of porous ceramics, can solve problems such as poor user experience, fluctuations, and inability to provide e-liquid on the atomizing surface, and achieve the effect of increasing the amount of atomization and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

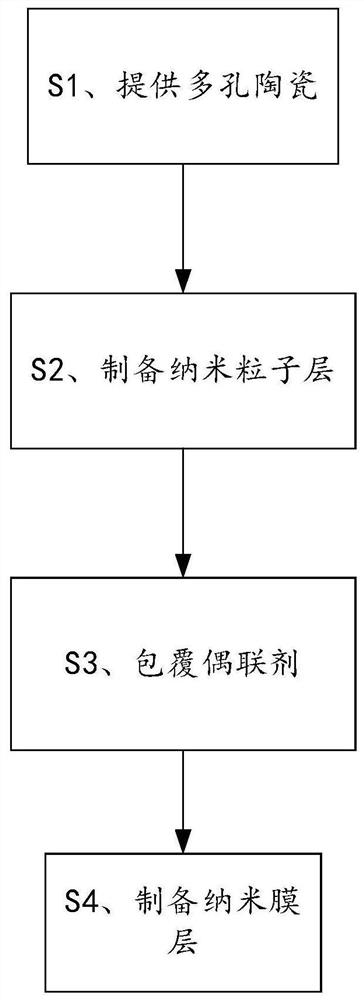

[0024] Such as figure 1 As shown, the preparation method of the porous ceramic atomizing core of this embodiment includes the following steps:

[0025] S1. Provide porous ceramics: provide porous ceramics for preparing atomizing cores. The preparation method of the porous ceramics is as follows:

[0026] S1.1. Surface modification of ceramic powder: After mixing the ceramic powder and the surface modifier, they are pretreated by ball milling together to obtain surface-modified ceramic powder.

[0027] Specifically, in this embodiment, natural microporous diatomite, mica or medical stone is used as the ceramic powder, and the particle size of the ceramic powder is 15 μm. After the ceramic powder is mixed with the surface modifier, ball milling pretreatment is carried out together to form a coating layer on the surface of the ceramic powder, and the surface modified ceramic powder is obtained after drying. The mass ratio of the ceramic powder to the surface modifier is 100:1, ...

Embodiment 2

[0046] Embodiment 2: The preparation method of the porous ceramic atomizing core of this embodiment, in order to make the porous ceramic atomizing core have a better lipophilic effect, in addition to the specific steps in Example 1, the following steps may also be included:

[0047] S3. Coating coupling agent: prepare a mixed solution of coupling agent and ethanol, and fully stir it to make it evenly mixed. The volume ratio of coupling agent and ethanol in the mixed solution is 2 to 5:100. The coupling agent is a silane coupling agent; soak the porous ceramic atomizing core covered with a nanoparticle layer into the mixed solution for 12-24 hours; take it out, wash it, and carry out drying treatment. The range is 80-110° C., the drying treatment time is 0.5-5 hours, and the porous ceramic atomizing core with the coupling agent adsorbed is obtained.

[0048] The coupling agent includes γ-aminopropyltriethoxysilane, γ-(2,3-epoxypropoxy)propyltrimethoxysilane, γ-(methacryloyloxy)...

Embodiment 3

[0051] Embodiment 3: The preparation method of the porous ceramic atomizing core of this embodiment, in order to make the adsorbed coupling agent more tightly bonded to the porous ceramic, in addition to the specific steps in Embodiment 2, the following steps may also be included:

[0052] S4. Preparation of a nano-film layer: the surface of the porous ceramic atomizing core adsorbed with a coupling agent is coated with a nano-film layer by low-temperature deposition (ALD), and the nano-film layer includes at least one of SiO2, Al2O3 or ZnO.

[0053] The preparation of the nano-film layer can stabilize the adsorbed coupling agent and reduce the possibility of its desorption on the porous ceramic surface. At the same time, it can also improve the lipophilicity of the atomizing core, making it easier for the e-liquid to penetrate.

[0054] In the most optimal embodiment of the preparation method of the porous ceramic atomizing core of the present invention, the surface of the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com