Manufacturing method of metal structure with 3D texture decoration effect

A metal structure and decorative effect technology, applied in special decorative structures, decorative arts, patterns imitating natural patterns, etc., can solve the problems of easy scratching and damage, poor simulation effect, high noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

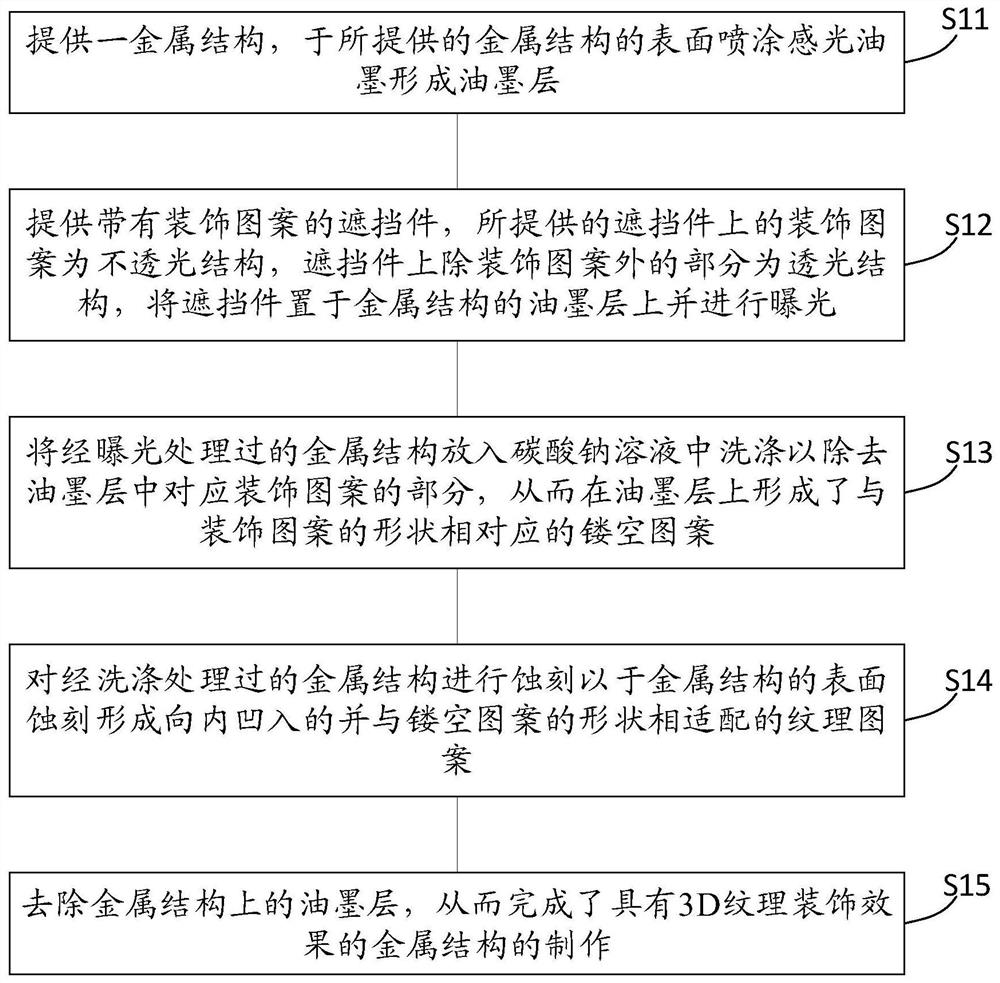

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

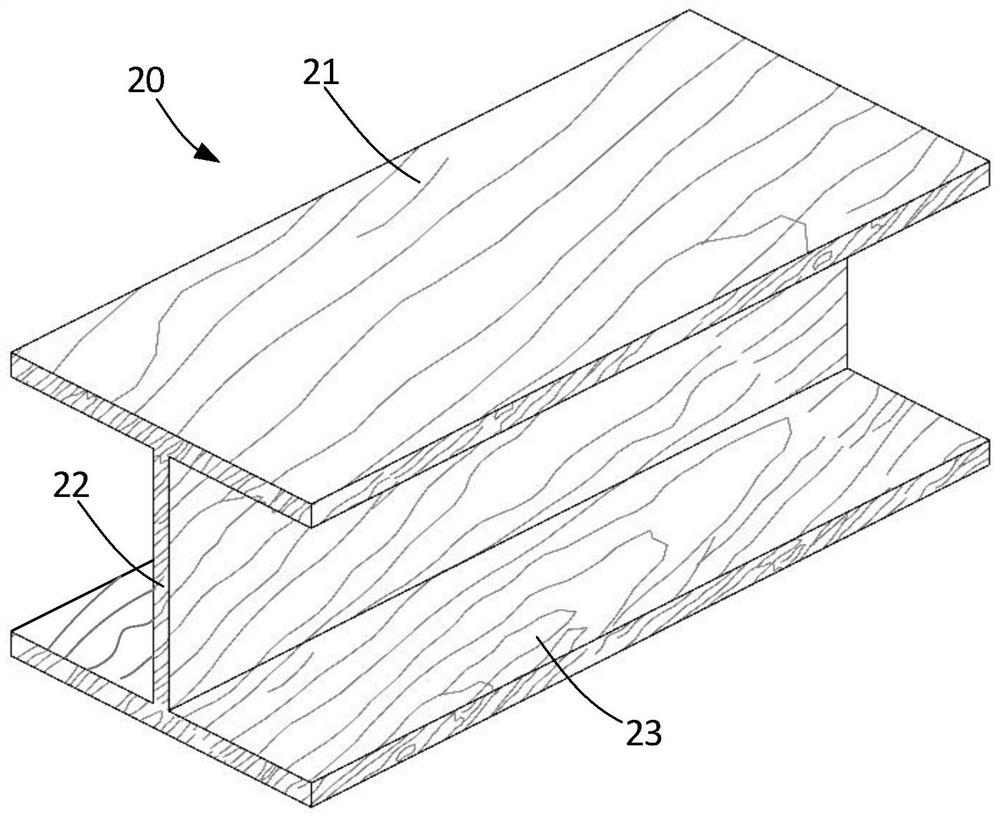

[0029] refer to figure 1 The present invention provides a method for manufacturing a metal structure with a 3D texture decoration effect, which is used for forming a 3D texture decoration effect on the surface of the metal structure. The 3D texture decoration effect formed by the production method of the present invention can form uneven texture shapes on the surface of the metal structure, and the texture patterns that play a decorative role are formed by these uneven textures, so as to improve the decorative effect and achieve real Concave-convex three-dimensional texture feel. Compared with the existing imitation wood grain technology, the production method of the present invention can realize more realistic wood grain texture and texture, and the wood grain shape is not easy to be scratched and damaged. In addition, compared with the unev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com