Polyester foaming process based on preparation of side cavity sound-absorbing cotton for automobile

A technology of sound-absorbing cotton and cavity, which is applied in applications, household appliances, household components, etc., can solve the problems of low efficiency and the inability to adjust the ratio of raw materials according to actual conditions, and achieve the effect of improving efficiency and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

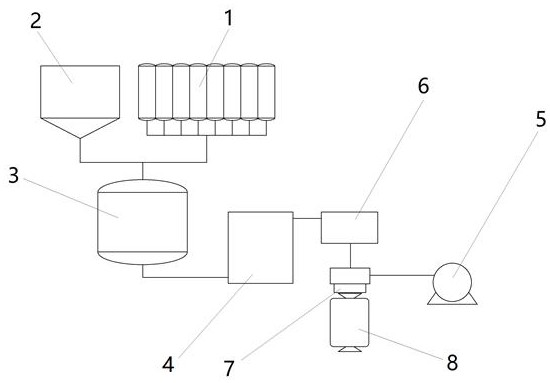

Method used

Image

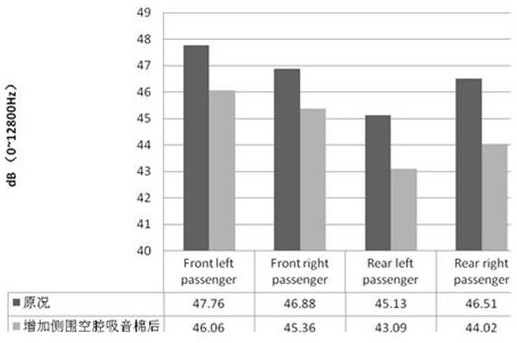

Examples

Embodiment 1

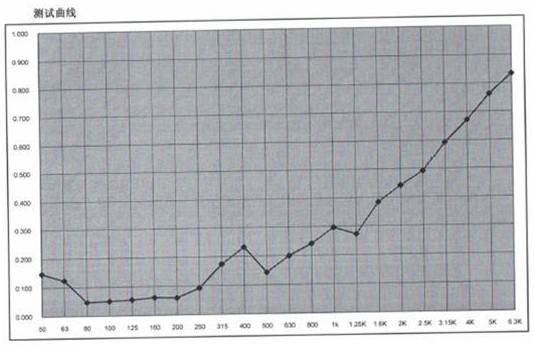

[0137] 1. Preparation of crushed foam

[0138] Broken foam is polyurethane foam material, which is composed of A and B components. The raw materials of the A component include polyester, water, composite stabilizer, starting catalyst, gel catalyst, leveling agent, crosslinking agent, composite catalyst and cell opening agent, and the B component is an isocyanate compound, specifically Polymethylene polyphenyl polyisocyanate is used. Among them, the gel catalyst is composed of 25% triethylenediamine and 75% 1,4 butanediol. As the cell opener, polybutadiene and fumed silica were used.

[0139] Concrete preparation steps are as follows:

[0140] (1) Mix the raw materials in component A, and add component B into the foaming machine separately, and set the flow rate of component A and component B: when setting the flow rate, turn on the high pressure, rotate the flowmeter, and set the flow rate to The actual high and low pressure flow is filled in, and the flow rate of componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com