A thermoplastic pervaporation polymer film and its preparation method and application

A thermoplastic polymer and polymer membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, permeation/dialysis water/sewage treatment, etc., can solve the problems of membrane performance limitation, volatilization speed control, uneven dispersion, etc., to achieve The cost of raw materials is low, the effect of realizing the production process and high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

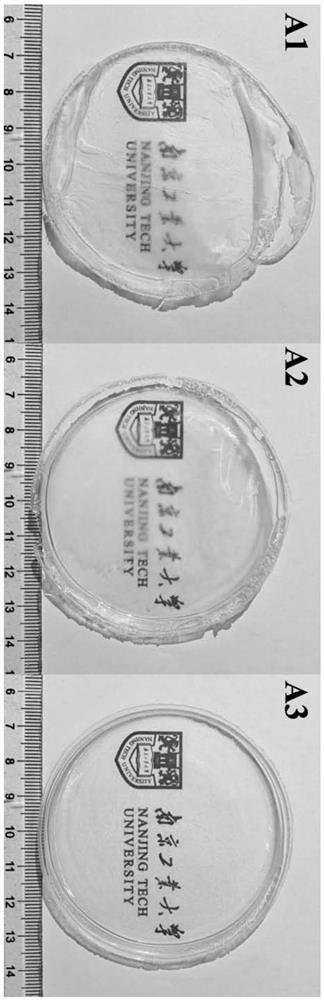

[0040] The PEBA1074 (purchased from Arkema) was put into a vacuum drying oven for drying. Take 1g of dried PEBA1074 polymer particles, put it in 19g of prepared solvent (the solvent is prepared by n-amyl alcohol and n-butanol in a mass ratio of 1:3), and put it in a constant temperature oil bath at 110°C at medium and high speed. Stir at the stirring speed for about 4-8 hours to ensure that it is completely dissolved and dispersed. After dispersing, let it stand for 1 hour in an oil bath at 95°C to complete defoaming.

[0041] Select three teflon Petri dishes and heat to above 80 °C. Pour the dissolved and defoamed casting solution into a petri dish while it is still hot, and then place the petri dish in a container with two sides open, and then place the whole device in a horizontal blast drying oven, and respectively at a certain speed. Inert gas purging at 105°C (initially, the solvent in the film casting liquid volatilizes and quickly reaches a saturated state in the clo...

Embodiment 2

[0046] The PEBA1074 (purchased from Arkema) was put into a vacuum drying oven for drying. Take 1g of dried PEBA1074 polymer particles, put it in 19g of prepared solvent (the solvent is prepared by n-amyl alcohol and n-butanol in a mass ratio of 1:1), and put it in a constant temperature oil bath at 110°C at medium and high speed. Stir at the stirring speed for about 4-8 hours to ensure that it is completely dissolved and dispersed. After dispersing, let stand for 1 h in an oil bath at 100 °C to complete deaeration.

[0047] Choose a teflon petri dish and heat to above 80 °C. Pour the dissolved and defoamed casting solution into a petri dish while it is still hot, then place the petri dish in a container with two sides open, and finally place it in a completely horizontal blast drying oven for drying, and add 2.5 mL / mL Inert gas purging at 105 °C for min (initially, the solvent in the casting solution volatilizes and quickly reaches saturation in the closed container, so that...

Embodiment 3

[0052] The PEBA1074 (purchased from Arkema) was put into a vacuum drying oven for drying. Take 1g of dried PEBA1074 polymer particles, put it in 19g of prepared solvent (the solvent is prepared by n-amyl alcohol and n-butanol in a mass ratio of 2:3), and put it in a constant temperature oil bath at 110°C at medium and high speed. Stir at the stirring speed for about 4-8 hours to ensure that it is completely dissolved and dispersed. After dispersing, let stand for 1 h in an oil bath at 100 °C to complete deaeration.

[0053] Choose a teflon Petri dish and heat to around 80°C. Pour the dissolved and defoamed casting solution into a petri dish while it is still hot, then place the petri dish in a container with two sides open, and finally place it in a completely horizontal blast drying oven for drying, and add 2.5 mL / mL Inert gas purging at 105 °C for min (initially, the solvent in the casting solution volatilizes and quickly reaches saturation in the closed container, so that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com