Preparation method of amyloid fiber iron oxide composite film and method for removing phosphate in tail water of municipal sewage treatment plant

A technology of amyloid protein and iron oxide, applied in water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor adsorption capacity of activated carbon and improve phosphorus removal performance , Environmental benefits are obvious, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the amyloid fiber iron oxide composite film of the present invention comprises the following steps

[0028] Step S1, weighing the functional protein and dissolving it in water, controlling the mass fraction to 5%-25%, adjusting the pH of the solution to 2.0-4.0 and placing it in a water bath at 80-100°C for 5-10 hours to obtain a protein fiber solution;

[0029] Step S2, weighing iron oxide and placing it in the protein fiber solution, controlling the mass fraction of Fe% to 2%-4%, adjusting the pH of the mixed solution to 3.5-5.5, stirring to make the mixture uniform, and obtaining a suspension B.

[0030] Step S3, put the diatomite powder in the water, control the mass fraction of the diatomite powder to 5%-20%, stir and mix thoroughly, record it as suspension A, and fully mix suspension A and suspension B , measured by the volume ratio of suspension A:suspension B, controlled at 1:1-3:1, mixed evenly and then filtered to form amyloid fiber i...

Embodiment 1

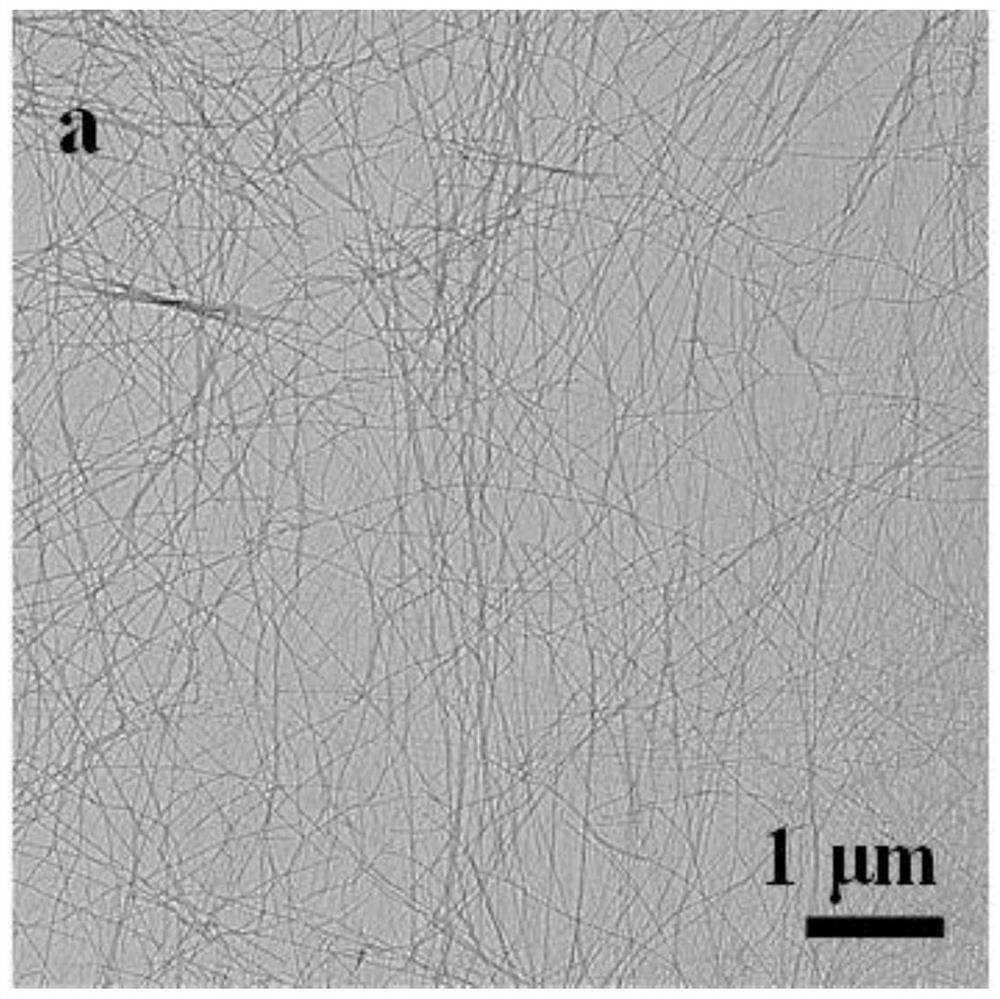

[0050] Accurately weigh 10g of bovine serum albumin and dissolve it in 190mL of pure water, adjust the pH of the solution to 2.0, and place it in a water bath at 80°C for 5 hours to obtain a protein fiber solution. Amyloid fibers with a diameter of about 5nm and a length of 2 microns can be obtained. The transmission electron microscope morphology of the resulting amyloid fibrils is as follows: figure 1 shown.

[0051] Weigh 5.8g of iron oxide and put it into the above protein fiber solution, mix thoroughly with a mixer, adjust the pH of the mixed solution to 3.5 with NaOH, and a large amount of white suspension appears, and the sub-10nm iron oxide amyloid fiber composite material is obtained, record Make suspension B.

[0052] Put 10g of 200-mesh diatomite powder in 190mL aqueous solution, stir and mix thoroughly, and record it as suspension A, 150mL of suspension A and 150mL of suspension B are fully mixed, then placed in a vacuum filtration device, and suction filtered Fo...

Embodiment 2

[0057] Accurately weigh 25g of lysozyme protein and dissolve it in 75mL of pure water, adjust the pH of the solution to 4.0, and place it in a water bath at 100°C for 10 hours to obtain a protein fiber solution, in which amyloid fibers with a diameter of about 5 nm and a length of 5 microns can be obtained.

[0058] Weigh 6g of iron oxide and place it in the above protein fiber solution, mix thoroughly with a mixer, adjust the pH of the mixed solution to 5.5 with NaOH, and a large amount of white suspension appears, and the sub-10nm iron oxide amyloid fiber composite material is obtained, which is denoted as Suspension B.

[0059] Put 40g of 200-mesh diatomite powder in 160mL aqueous solution, stir and mix thoroughly, and record it as suspension A, fully mix 120mL of suspension A with 40mL of suspension B, then place it in a vacuum filtration device, and Filtrate into a film to obtain a thickness of 2.3mm and a density of 0.1535g / mm 3 Amyloid fiber iron oxide composite film (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com