Calculation and real-time monitoring method for blast furnace tuyere rotation zone boundary

A real-time monitoring and swing zone technology, applied in the field of blast furnace ironmaking technology, can solve the problems of difficult real-time monitoring, long time consumption, inability to reflect the experimental model well, and achieve the effect of ensuring the safety of life and property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

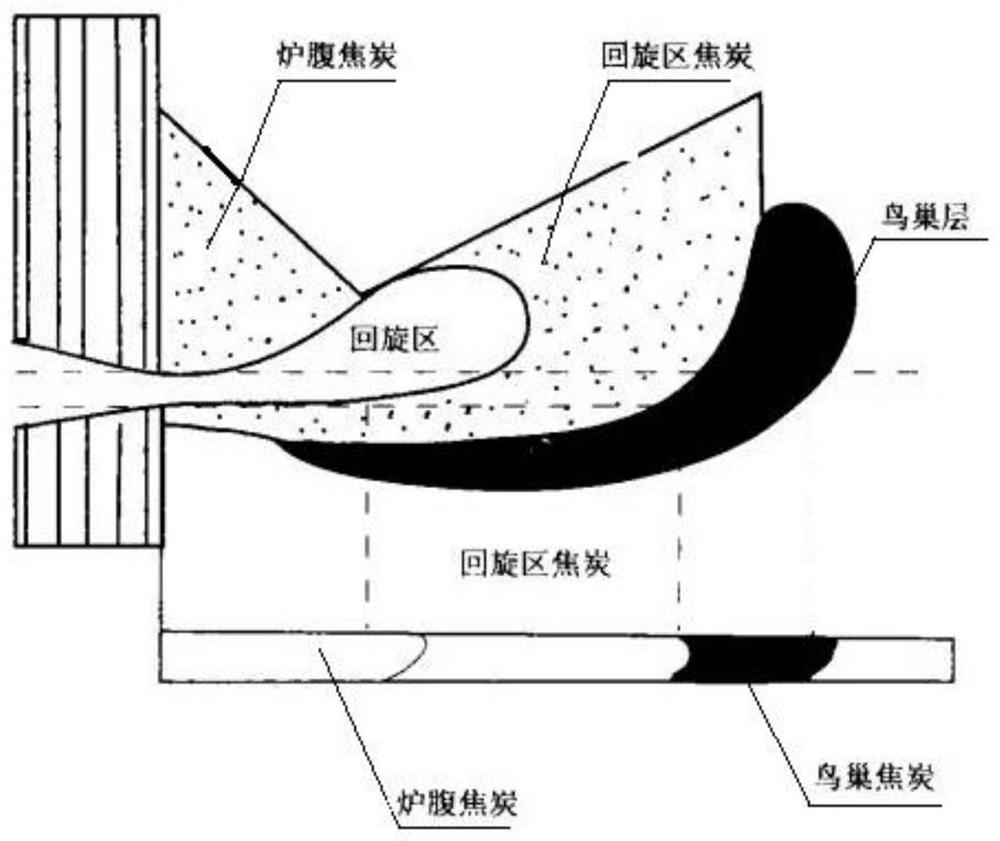

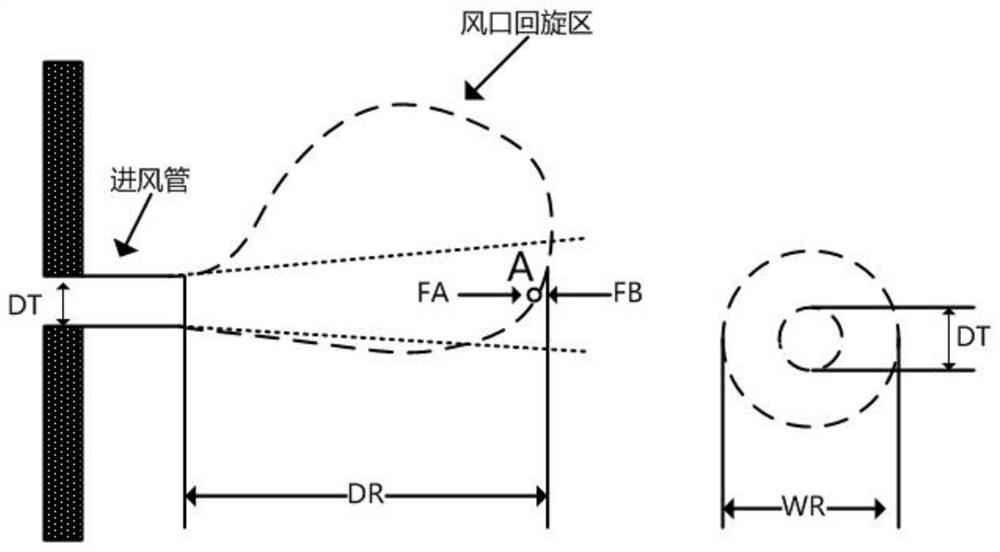

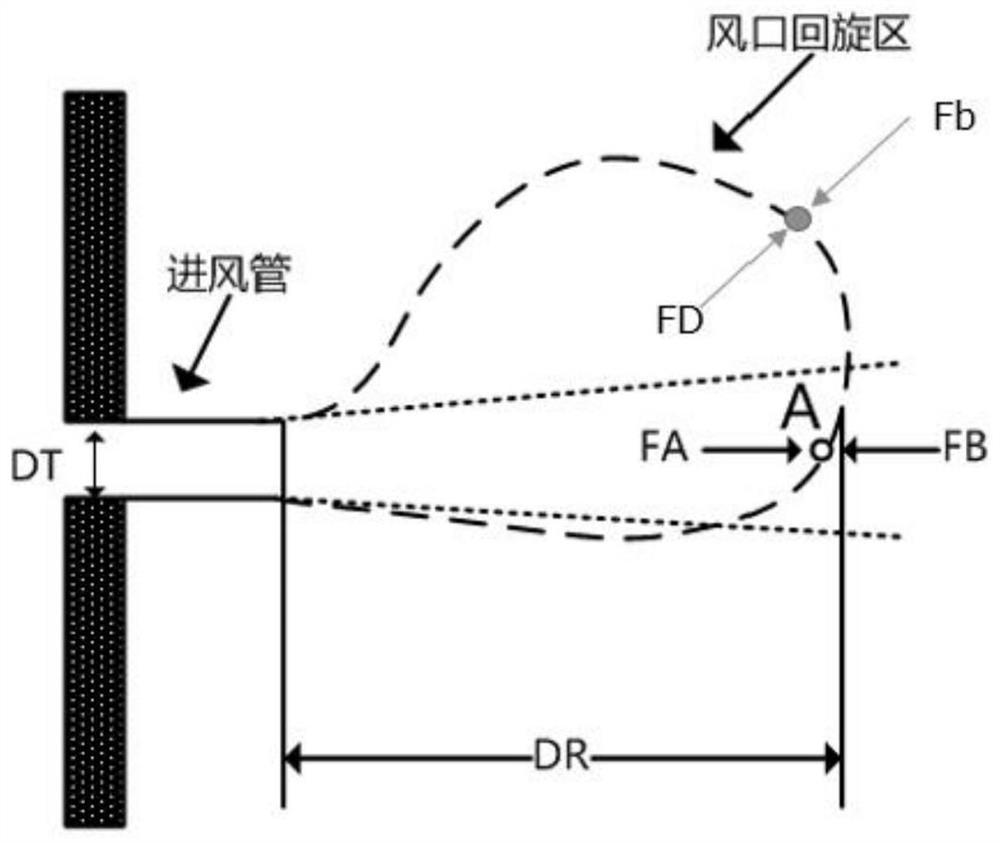

[0047] The blast furnace tuyere swirl area is formed as figure 1 As shown, in the blast furnace ironmaking process, the blast has strong kinetic energy when it leaves the tuyere. It blows the coke in front of the tuyere and reacts with it, forming a loose and approximately elliptical gas phase cavity at the front edge of the tuyere. . In addition, the gas flow in front of the tuyere takes the swirl area as the radiation center, and develops along the center of the hearth in the long radial direction, and develops along the two sides of the short radial direction. The carbon revolves in the cavity, and this area is the blast furnace tuyere swirling area. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com