Waterproof construction method for electric smoke exhaust window of color steel tile roof

A construction method and technology for smoke exhaust windows, applied in roof drainage, roofing, roof covering and other directions, can solve problems such as poor corporate reputation, aging sealant, instability, etc., and achieve overall quality control and reduce leakage. , The effect of reducing post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

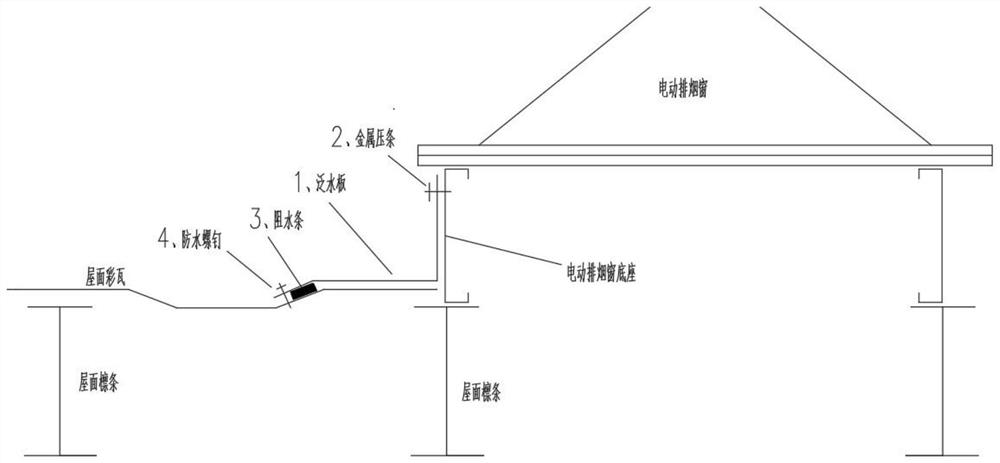

[0019] Such as figure 1 As shown, a waterproof construction method at the electric smoke exhaust window of a color steel tile roof of the present embodiment, the steps are:

[0020] Step 1: Make flashing board 1. According to the regulations, first cut a piece of colored tile with a width of 500mm and the same length as the electric smoke exhaust window, with a thickness of 0.6mm. Fold the colored tile to the flashing board according to the roof panel type and the height of the skylight shape, place the finished flashing plate 1 on the lower opening of the skylight;

[0021] Step 2: Make metal bead 2, the material is galvanized flat iron with a thickness of 2mm. After laying down the material, fix the upper end of flashing plate 1 with the base of the electric smoke exhaust window with screws, and fix the connection between the flashing plate and the base of the skylight with metal bead 2 , can effectively prevent rainwater from infiltrating from the upper opening;

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com