Wall structure and wall construction method

A technology of wall structure and construction method, which is applied in the direction of building components, building structure, insulation, etc., can solve the problems of high risk, different shrinkage force, uneven mortar ratio, etc., to reduce construction risk, improve construction efficiency, The effect of high construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

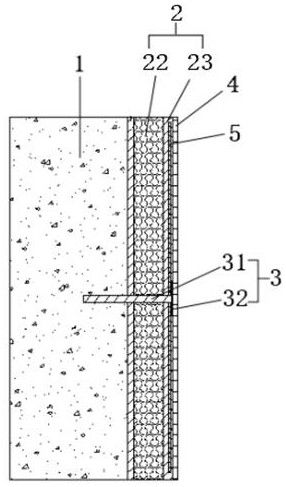

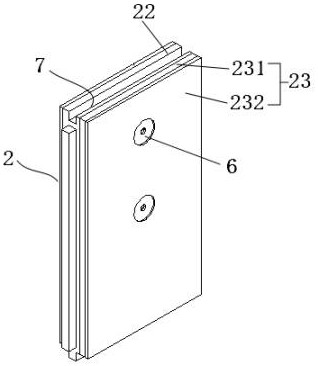

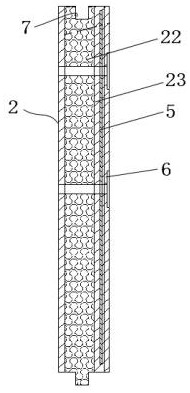

[0031] Such as Figure 1 to Figure 4 As shown, the specific embodiment provides a wall structure, including a base wall 1 and a composite insulation board 2, a plurality of composite insulation boards 2 are arranged on the outside of the base wall 1, and connectors are arranged on the composite insulation board 2 3. The connector 3 passes through the composite thermal insulation board 2 and connects the composite thermal insulation board 2 with the base wall 1; outside; the wall structure does not have a thick plaster layer constructed on site outside the composite insulation board 2. The outer surface of the composite insulation board 2 is a flat surface, which is a mirror surface in some embodiments, and a non-mirror surface in other embodiments. When it is a non-mirror surface, it can be puttyed to form a putty layer. Wherein, the mirror surface refers to a surface with a relatively flat surface, and the non-mirror surface refers to a surface with a concave-convex structur...

specific Embodiment approach 2

[0036] This specific embodiment provides a kind of wall construction method, comprises the following steps:

[0037] A1: Wall reinforcement binding;

[0038] A2: Support the high-precision outer formwork of the wall, install the composite insulation board 2, the composite insulation board 2 is located inside the high-precision outer formwork, support the inner formwork, and connect the inner formwork and high-precision outer formwork through pull bolts;

[0039] A3: Pass the connector 3 through the composite insulation board 2, and the connector 3 extends into the cavity between the composite insulation board 2 and the inner template;

[0040] A4: Pour concrete into the cavity between the composite insulation board 2 and the inner formwork;

[0041] A5: Maintenance and form removal, no thick plastering construction on the outside of the composite insulation board 2;

[0042] Wherein, the composite thermal insulation board 2 includes a thermal insulation board matrix 22 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com